Twisting machine used for compound double twisting

A technology of twisting machine and two-for-one twisting spindle, which is applied in the field of compound two-for-one twisting twisting machine, which can solve the problems of large and complex twisting machine structure, shortened production process, inconvenient adjustment of twist ratio, etc., and achieves simple structure, easy replacement Easy to adjust and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

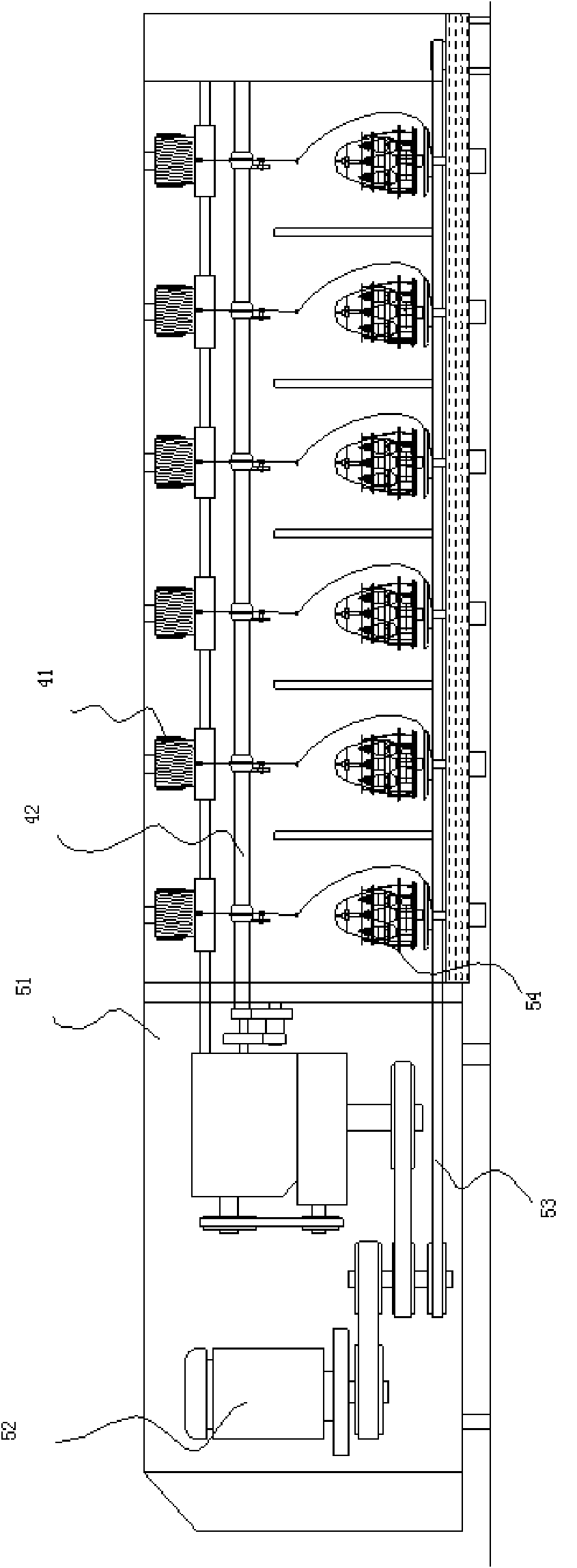

[0035] Such as figure 1 and 7 As shown, a twisting machine for compound two-for-one twisting includes a frame 51, on which a motor 52 is installed, and the motor 52 drives a plurality of simultaneously running twisting devices fixed on the frame 51 through a transmission belt 53 54, each twisting device 54 is connected with its corresponding yarn winding device.

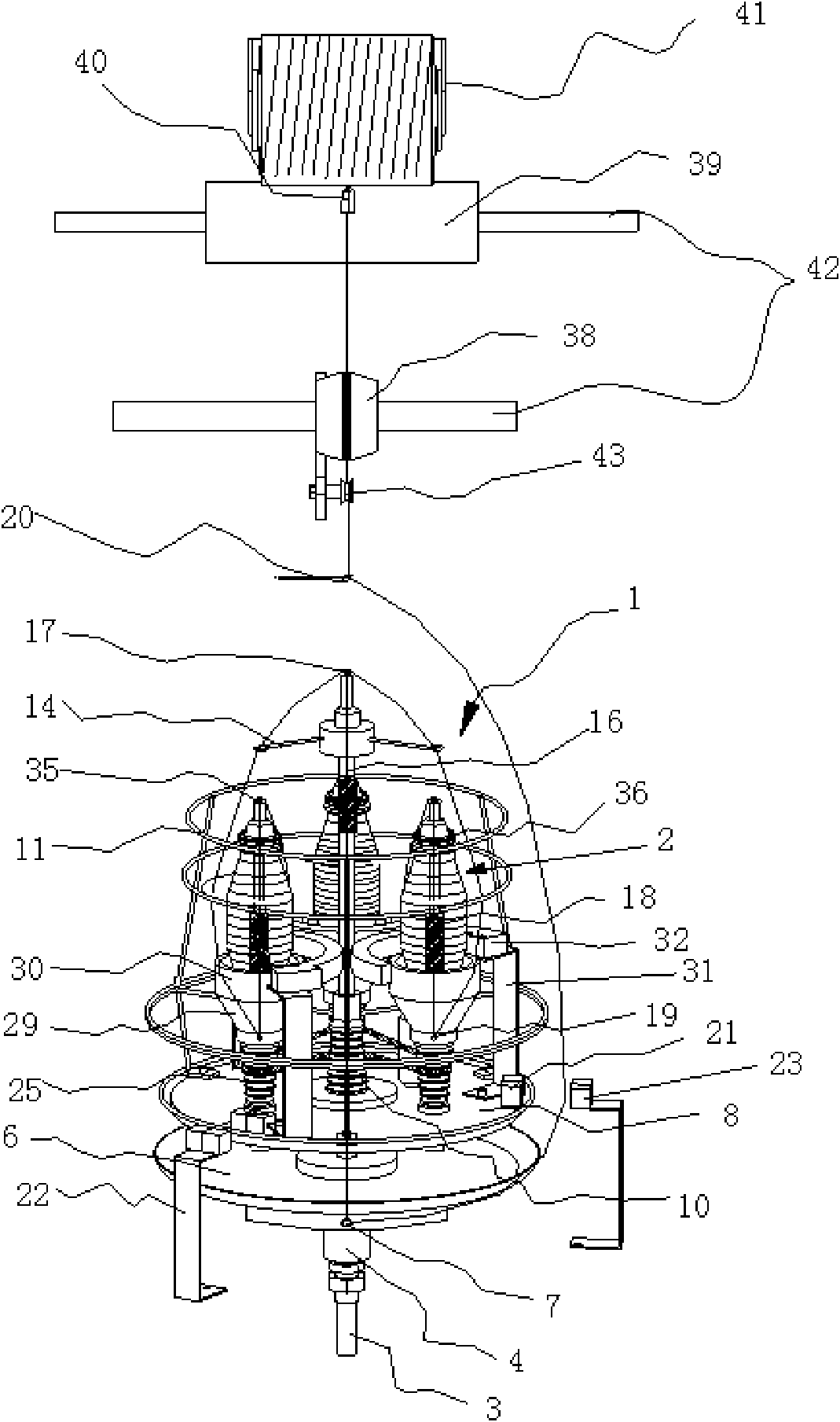

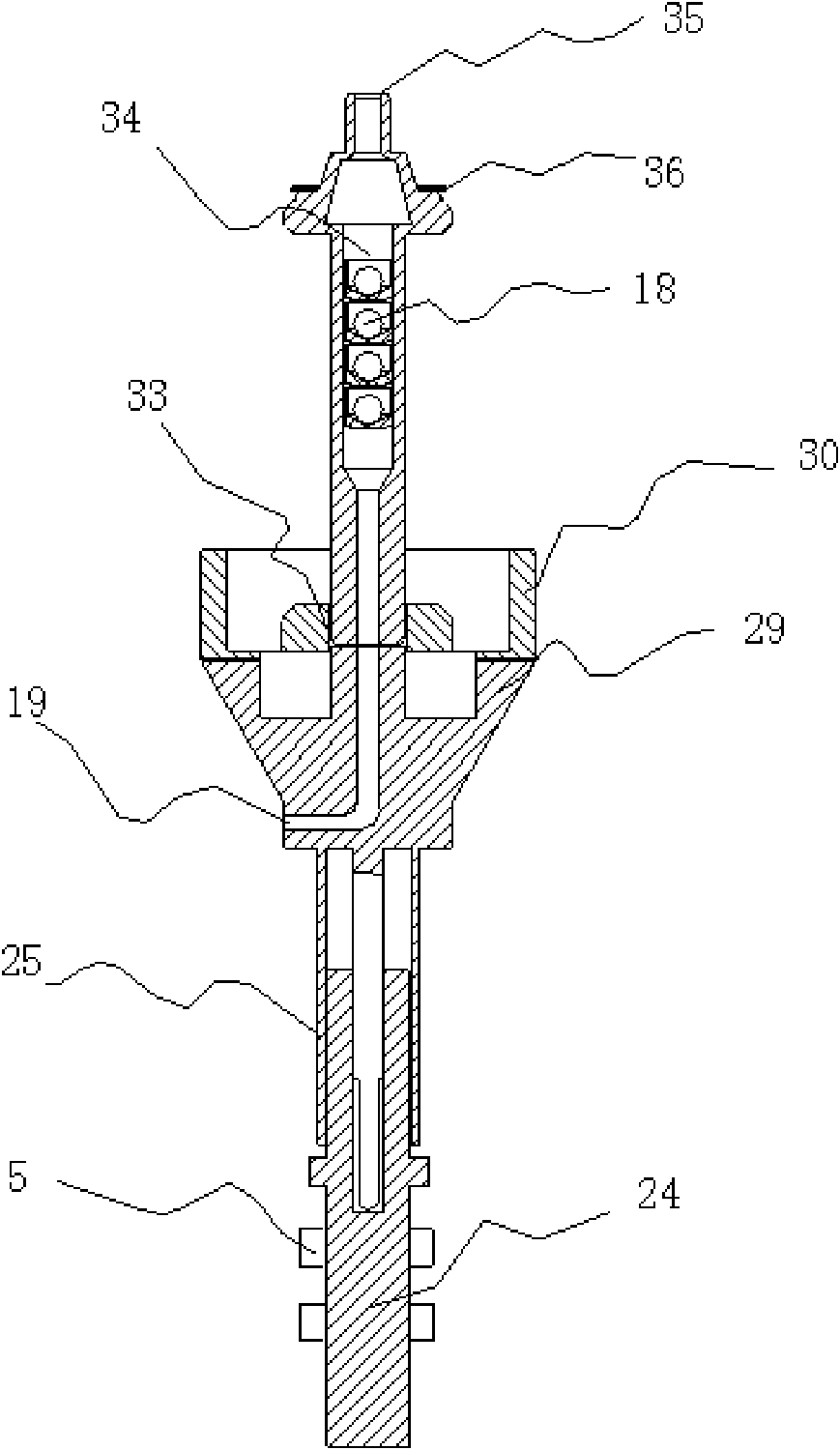

[0036] Such as figure 2 As shown, the twisting device includes three primary twisting two-for-one twisting spindles 2 and one double-twisting spindle 1, the double-twisting spindle 1 includes a double-twisting spindle foot 3, and the double-twisting spindle 1 is fixed on the frame 51 through the double-twisting spindle foot 3 Above, the movable retwisting spindle disk 4 is socketed on the retwisting spindle foot 3, and the retwisting spindle disk 4 is driven to rotate by the motor 52 through the transmission belt 53. A circular twisting and twisting disc 6 is sleeved above the twisting spindle disc 4 , and a twis...

Embodiment 2

[0041] Such as Figure 8 and 9 Shown in and 10, a kind of twisting machine of compound two-for-one twisting comprises frame 51, and a plurality of twisting devices and yarn winding devices corresponding to twisting devices are installed on frame 51, wherein twisting devices include The double-twisting spindle 1 and the two-for-one twisting spindle 2 located on the mounting plate 8 of the double-twisting spindle 1. Above the first twist static spindle disk 30 of each two-for-one twisting spindle 2 is provided with a first twist balloon ring 61, and the first twist balloon ring 61 is fixed on the inner diameter of one of the balloon rings 13 of the balloon ring guide frame 11. The outer magnet 32 on the two-for-one twisting spindle 2 is fixed on the wire guide tube 16 of the two-for-one twisting spindle 1 . The retwisting spindle 1 includes retwisting spindle discs 4, and each retwisting spindle disc 4 is directly driven by a small motor 62. All the other are identical with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com