Production method of all-cotton high-tenacity double-faced polyester peach skin knitted fabric and shell fabric thereof

A production method and fabric technology, applied in the direction of fabric surface trimming, knitting, weft knitting, etc., can solve the problems of inability to wear, great damage, and frayed fabrics, and achieve excellent anti-pilling performance, soft hand feeling, powerful high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

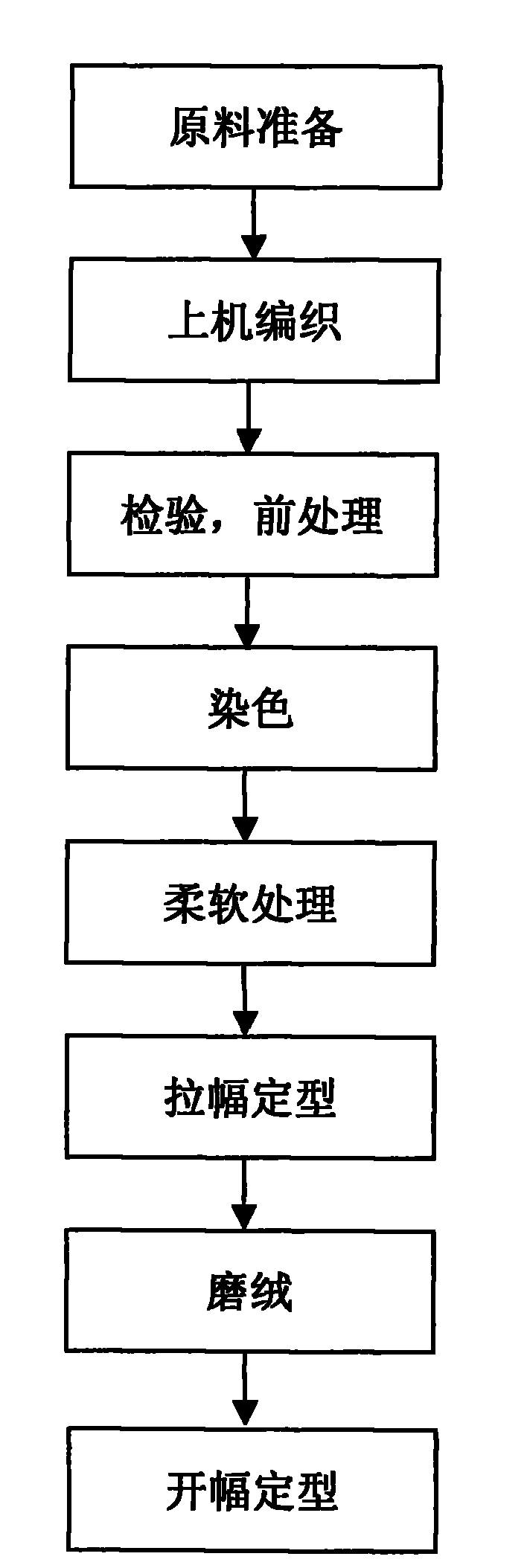

[0026] The technical scheme of the present invention is to select 100% cotton yarn count raw material, adopt double-sided structure, and then produce through pretreatment, dyeing, tenter drying, sanding, and open-width setting. Its process is carried out in the following order (see figure 1 ):

[0027] 1. Raw material preparation,

[0028] The hand feeling of the fabric is required to be extremely soft, and it has to be sanded, which has extremely high requirements on raw materials, that is, the yarn count must meet the requirements of sanding and fabric strength, and it must also reflect the high-grade fabric. Flower shells and neps are also highly required. Therefore, in order to show the grade of the fabric, you can choose 100% combed cotton yarn with a count of 28 S ~80 S , such as 36 S , 40 S , 50 S , 60 S Wait. It is appropriate to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com