Unbalanced shaft

A balanced shaft, balanced technology, applied in the field of unbalanced shafts, can solve the problems of no lubricant inlet, wear of rolling contacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

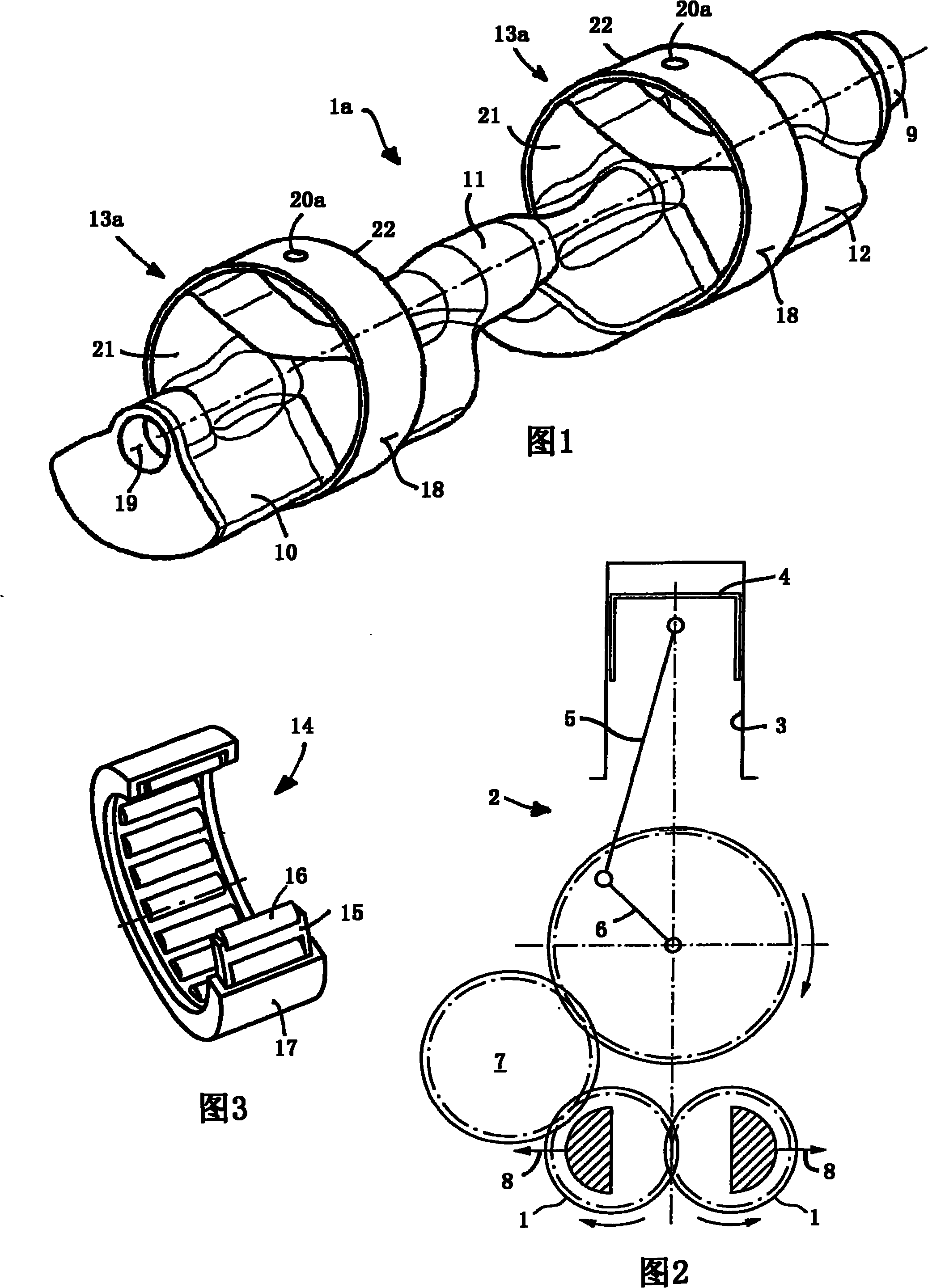

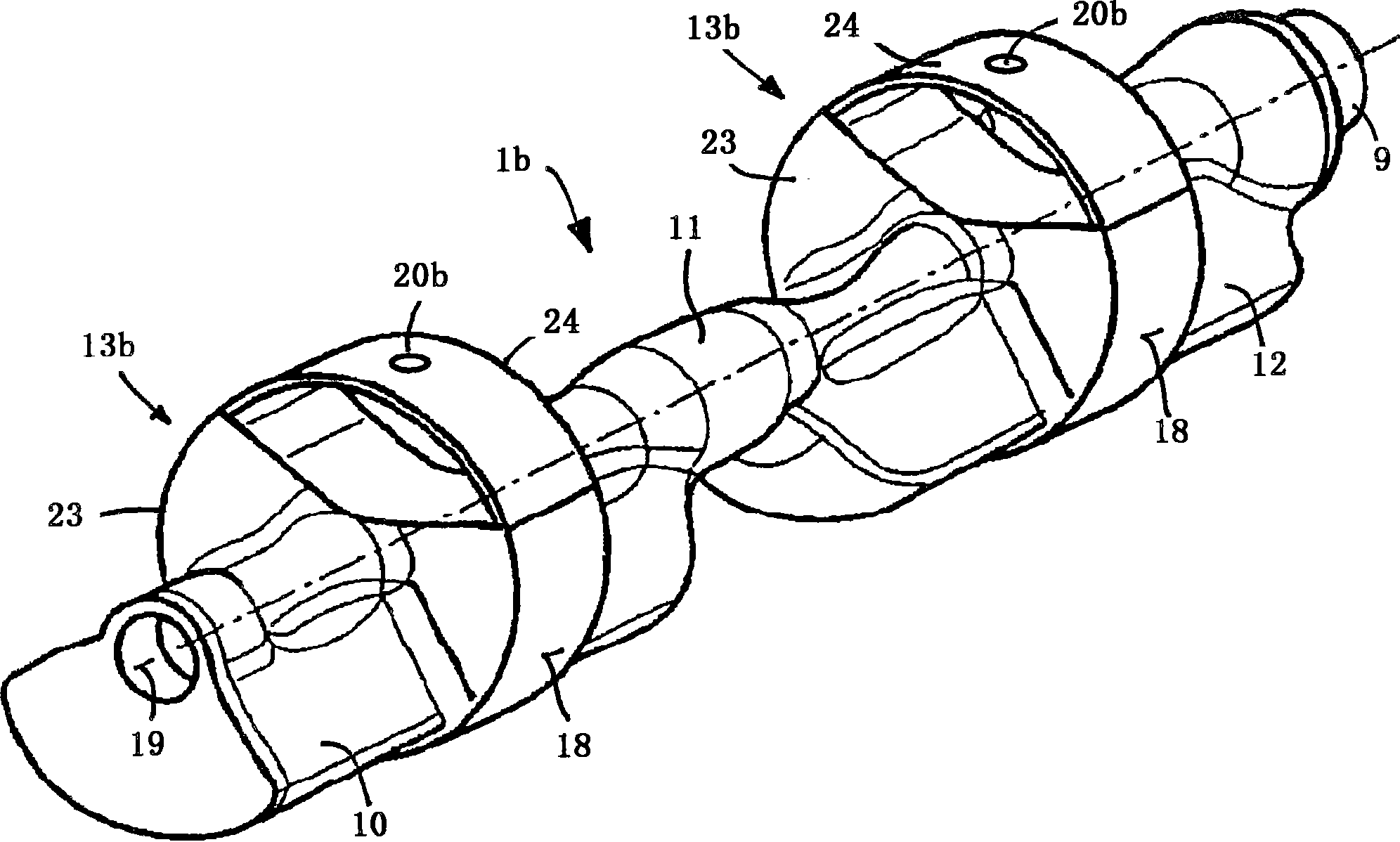

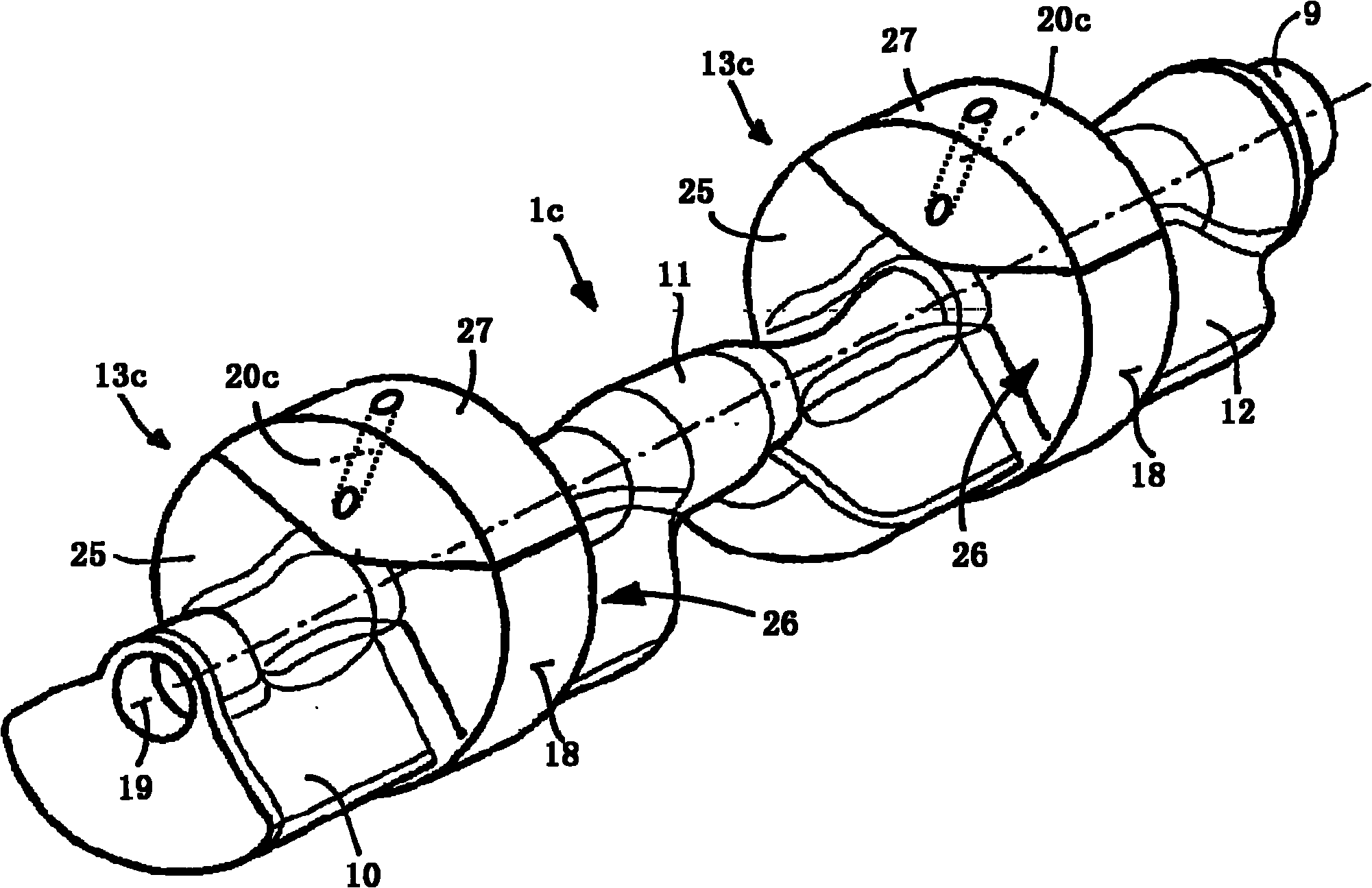

[0016] exist figure 1 , 4 Shown in and 5 is the unbalance shaft 1, which is used to balance the second-order inertial forces of a piston internal combustion engine in a four-cylinder in-line configuration (Vierzylinder-Reihenbauweise). This mass-balance transmission, also known as Lancaster balance (Lancaster-Ausgleich), is produced by figure 2 It is known from the schematic diagram of the transmission shown in . Internal combustion engine 2 includes four pistons 4 oscillating in cylinders 3 , the longitudinal movement of which is converted into rotation of a crankshaft 6 via connecting rods 5 . This drives (here via the intermediate shaft 7 ) the two unbalance shafts 1 with unbalance bodies 8 , wherein the unbalance shafts 1 rotate parallel to the crankshaft 6 in opposite directions at double the crankshaft speed.

[0017] The unbalanced shaft 1 , which is driven on the drive section 9 , for example via sprockets or gears not shown, comprises three shaft sections 10 , 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com