Anti-condensation refrigerator and anti-condensation control method

An anti-condensation and refrigerator technology, used in program control, computer control, household refrigerators, etc., can solve the problems of slow response of relay mechanical contacts, low frequency of heating wire on and off, waste of energy consumption, etc., to reduce energy consumption. Consumption, small temperature fluctuation, accurate control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

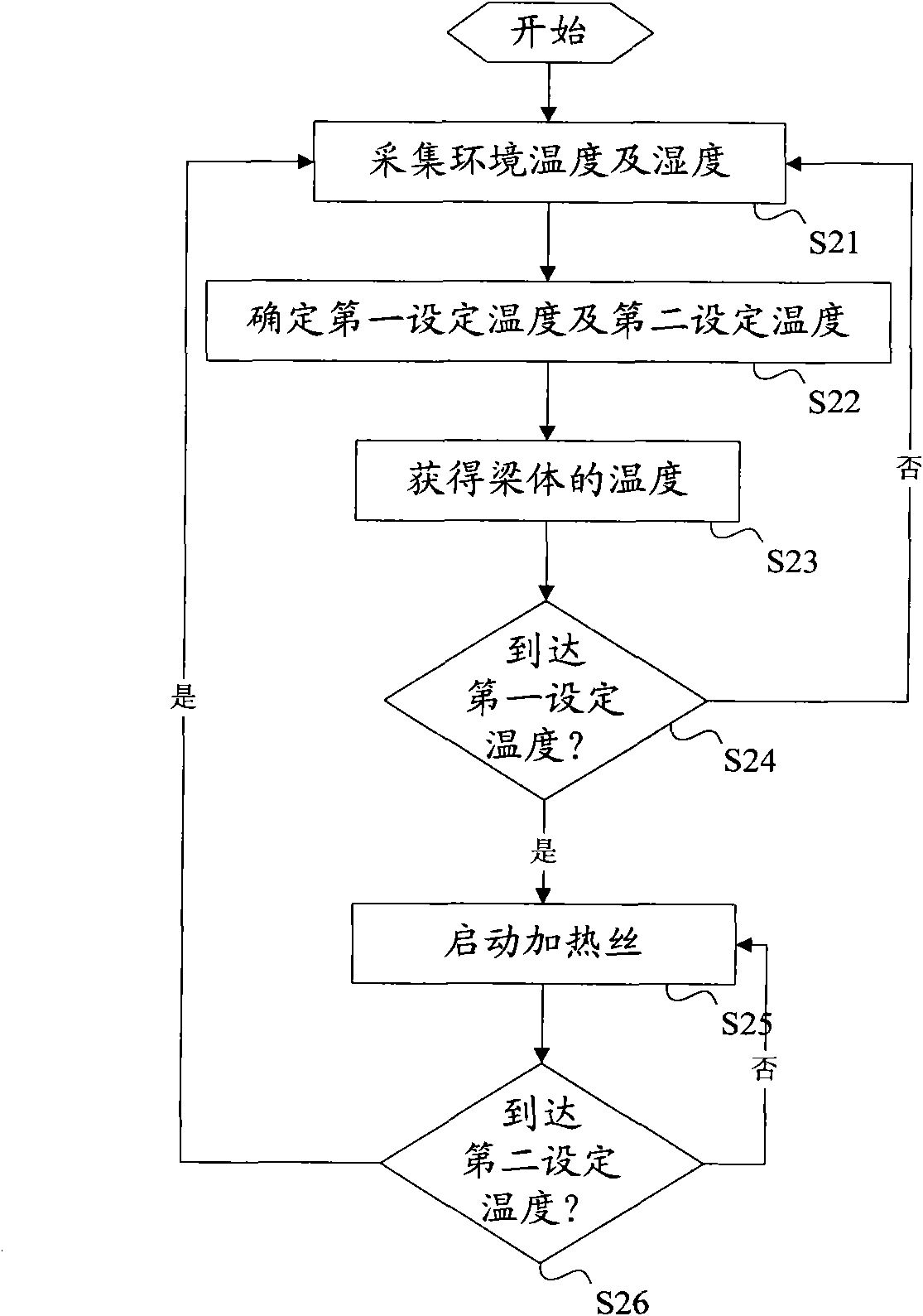

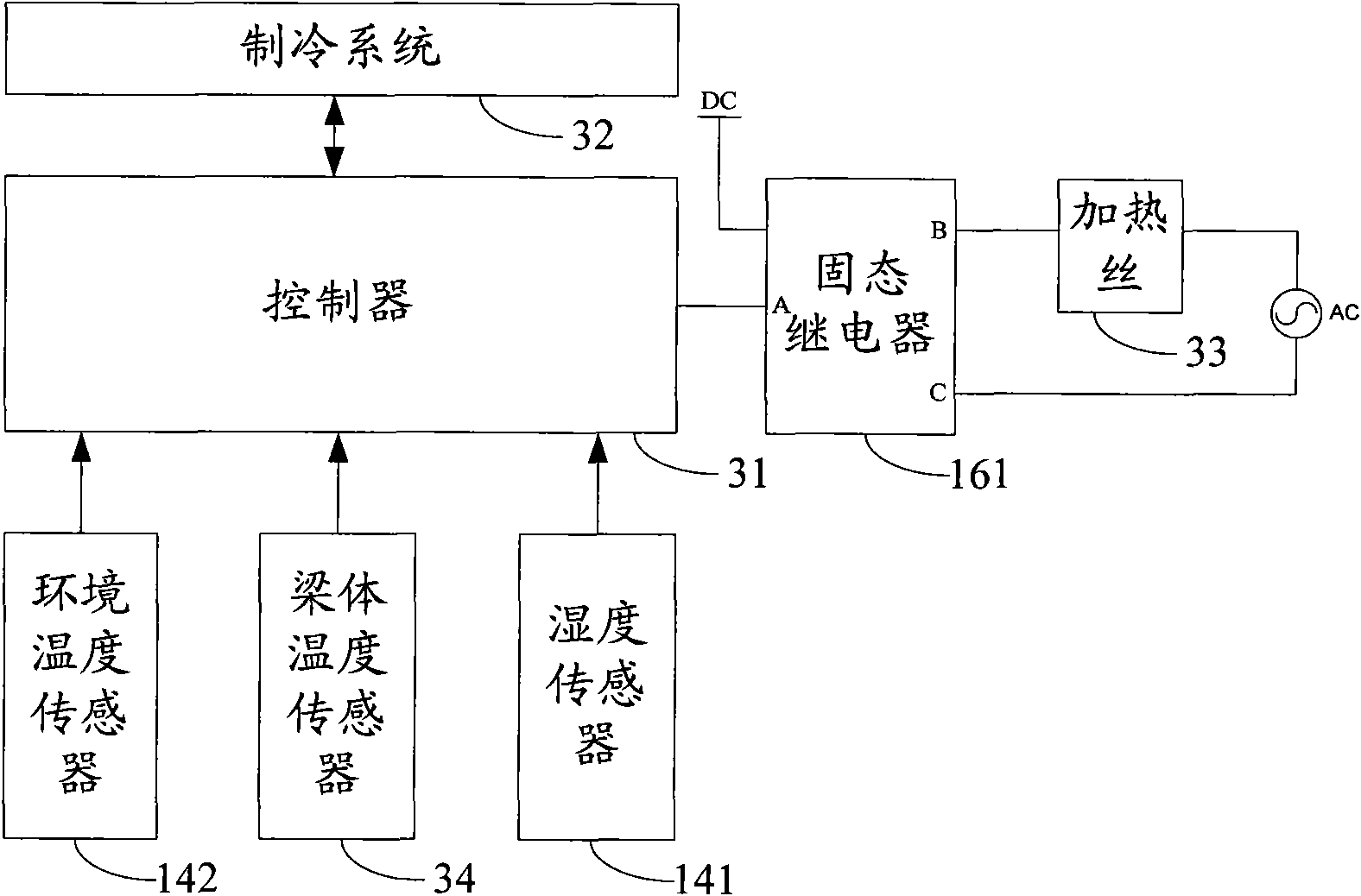

[0038] First, the principle of the present invention is briefly explained. In the present invention, a non-contact switch device is set to control the start and stop of the heating device, so that the control speed is increased, and the temperature fluctuation is further reduced. And by arranging a temperature sensor at the beam body (the general designation for the body of the sealing beam and the dividing beam), the temperature obtained is compared with the first set temperature obtained in real time by ambient temperature and humidity to control the start and stop of the heating device , making the control more scientific and accurate, and reducing energy consumption.

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

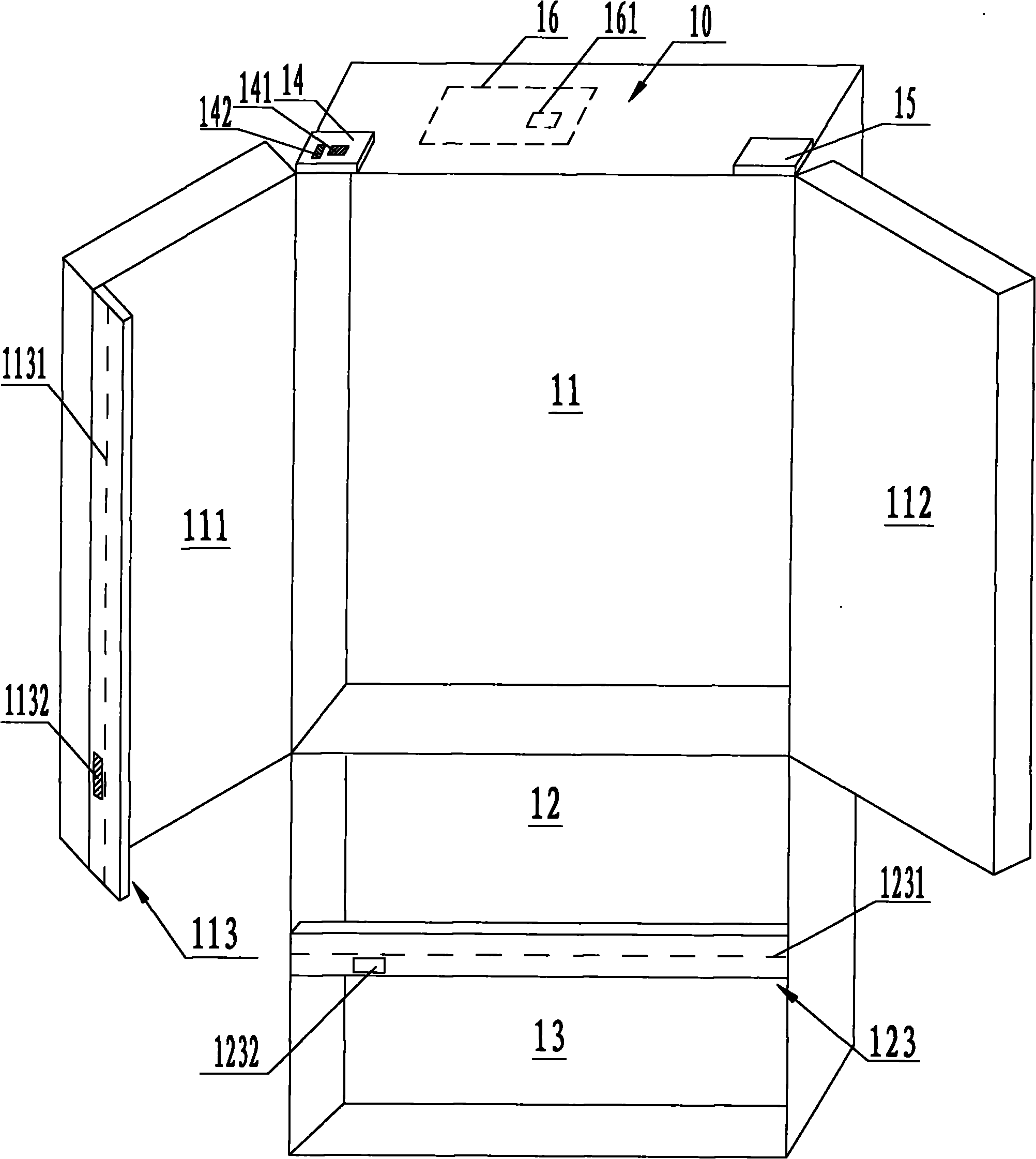

[0040] refer to figure 1 , shows a schematic structural view of an embodiment of the anti-condensation refrigerator of the present invention. As shown in the figure, it includes a box body 10; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com