Thermoelectric module and optical transmission apparatus

A thermoelectric module and thermoelectric conversion technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of slow heat conduction, long distance, and inability to maintain the temperature of the laser diode at the specified temperature, so as to simplify wire bonding and improve reliability. Excellent performance and responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

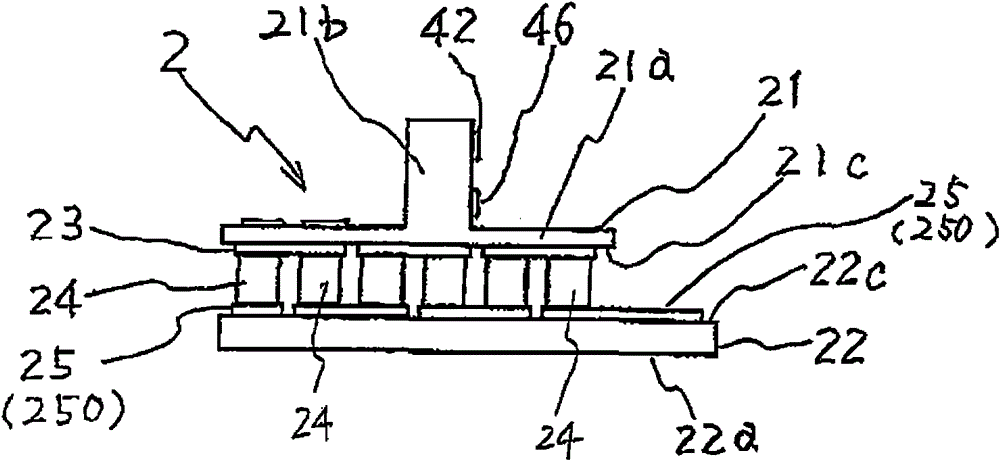

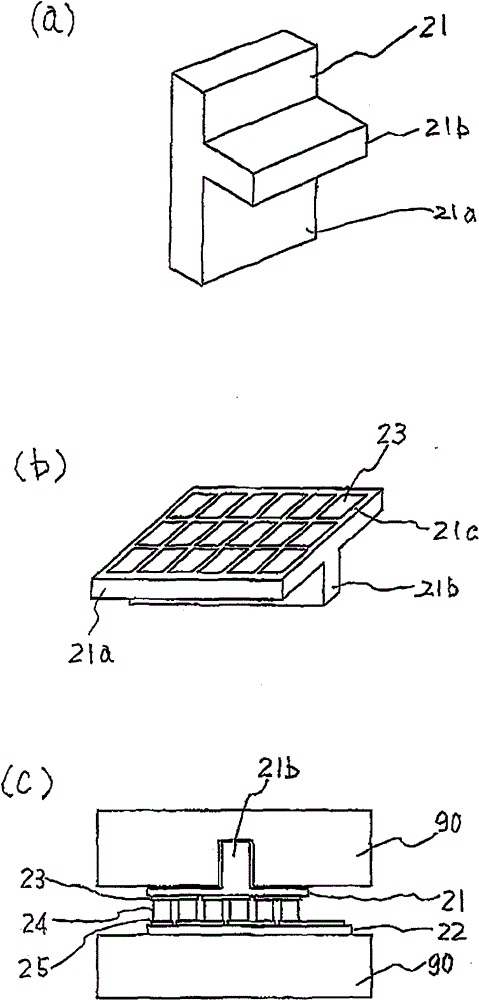

[0035] figure 1 A thermoelectric module 2 according to Embodiment 1 of the present invention is schematically shown. figure 2 is an explanatory diagram schematically showing the state of manufacturing the thermoelectric module 2 of Example 1, Figure 5 An optical transmission device 1 incorporating a thermoelectric module 2 is schematically shown.

[0036] Such as figure 1 As shown, the thermoelectric module 2 has a first insulating substrate 21 , a second insulating substrate 22 , a plurality of electrodes for thermoelectric conversion elements (hereinafter referred to as electrodes) 23 and 25 , and a plurality of thermoelectric conversion elements 24 .

[0037] The first insulating substrate 21 is made of alumina, such as figure 1 The cross-section shown is convex, and the first insulating substrate 21 has a substrate main body portion 21a and a convex portion 21b. The substrate main body portion 21a has a long plate shape. The convex part 21b is connected to the cente...

Embodiment 2

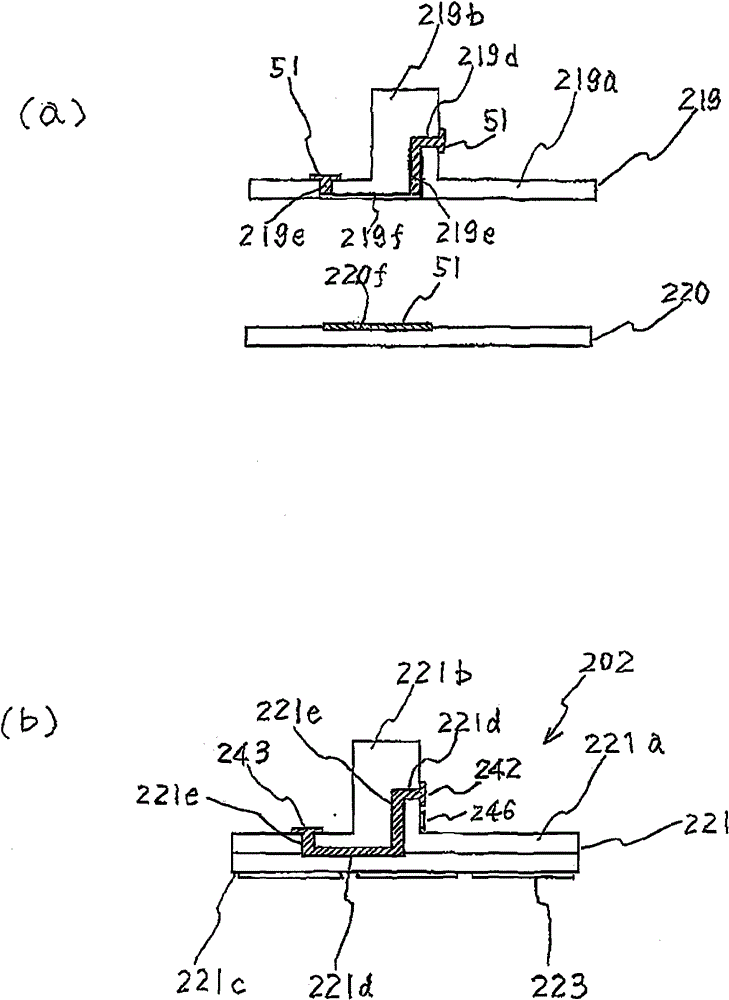

[0044] Next, refer to image 3 , the thermoelectric module 202 in which the first insulating substrate has two layers is described. In addition, in Embodiment 2, the integration process of the first insulating substrate 21 and the second insulating substrate 22 and the structure of the second insulating substrate are the same as those of Embodiment 1, so the description is omitted, and only the structure different from that of Embodiment 1 will be described. the first insulating substrate.

[0045] Such as image 3 As shown in (a), the alumina mixed material in the form of slurry is prepared, and the first insulating substrate intermediate molded product 219 and the flat plate-shaped first insulating substrate intermediate molded product 220 are formed respectively. Afterwards, on the first insulating substrate intermediate molded product 219, the horizontal conduction circuit hole 219d, the vertical conduction circuit hole 219e, and the horizontal conduction circuit hole gr...

Embodiment 3

[0048] Next, refer to Figure 4 , illustrating the thermoelectric module 302 . in addition, Figure 4 The structure shown is in image 3 In terms of structure, the thermistor 344 is mounted on the convex portion 319b, the integration process of the first insulating substrate and the second insulating substrate and the structure of the second insulating substrate are the same as those of the first embodiment, so the description is omitted, and only the same as that of the first embodiment is described. 1 different first insulating substrates.

[0049] Such as Figure 4 As shown in (a), the alumina mixed material in the form of slurry is prepared, and the first insulating substrate intermediate molded product 319 having a substantially square-shaped cross section and the first insulating substrate intermediate molded product 320 having a flat plate shape are respectively molded. Afterwards, the horizontal conductive circuit hole 319d, the vertical conductive circuit hole 319...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com