Forming occlusion mechanism of air duct hydraulic elbow forming machine

A molding machine and hydraulic technology, which is applied in the production of gas pipe connecting elbows and the field of elbow molding machines, can solve the problems of low single-station efficiency and poor molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

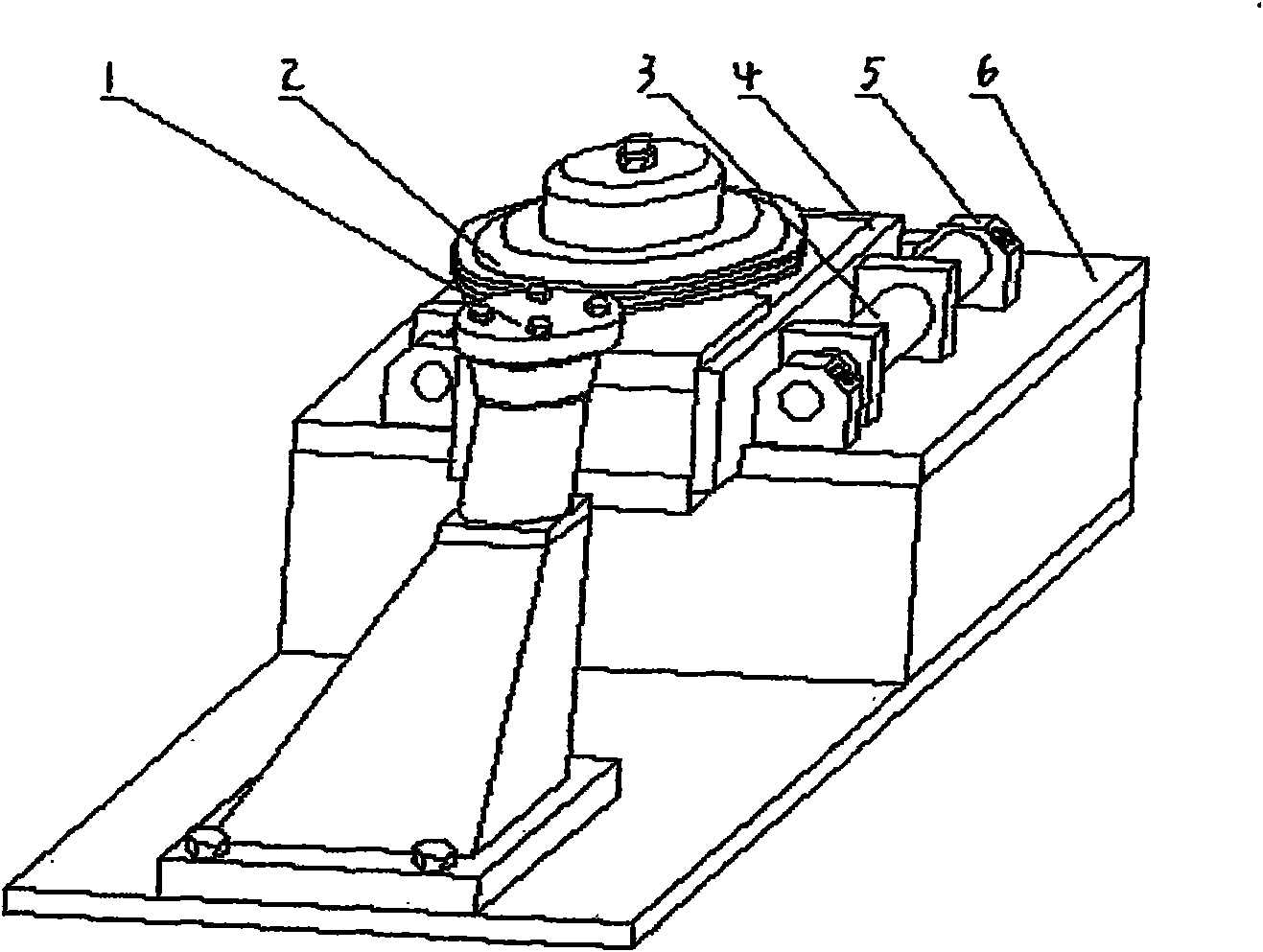

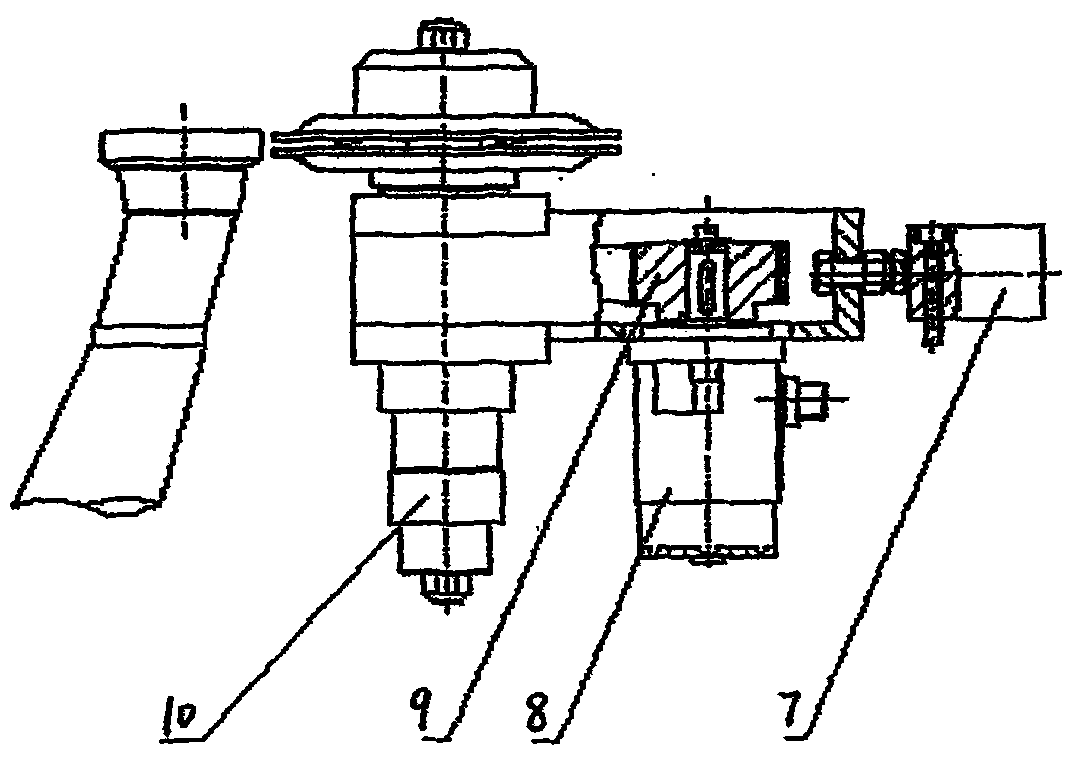

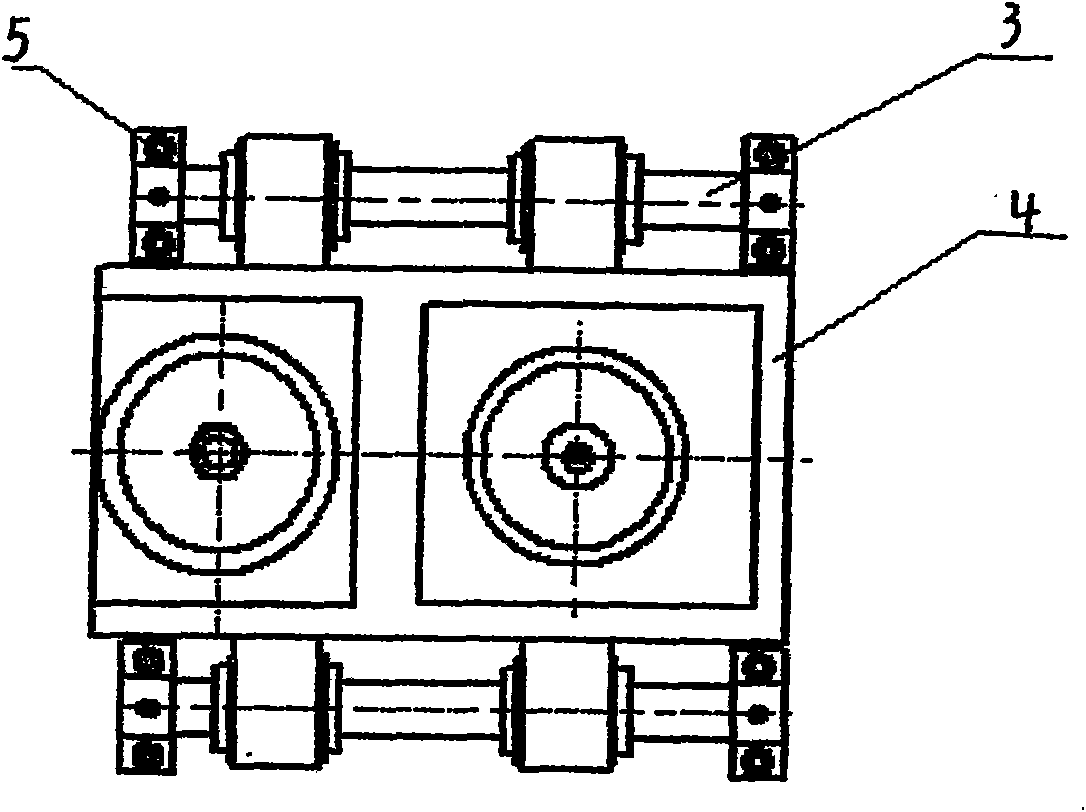

[0014] see Figure 1~3 , the forming occlusal mechanism of the air duct hydraulic elbow forming machine of the present invention is mainly composed of an installation frame 6, a positioning guide rod 3, an installation seat 5, a movable support 4, a hydraulic motor 8, an occlusal cylinder 10, a power transmission wheel 9, an upper and lower Forming wheel 2, thrust oil cylinder 7 and wheel mechanism 1 form. The installation frame 6 is installed on the box body of the air duct hydraulic elbow forming machine. There are two positioning guide rods 3, which are installed on the installation frame 6 through the mounting base 5, one left and one right, and the movable support 4 is slidingly connected. On the two positioning guide rods 3, the hydraulic motor 8 and the occlusal cylinder 10 are vertically installed on the movable support 4, and the power transmission wheel 9 is installed on the output end of the hydraulic motor 8, and the power transmission wheel 9 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com