Grinding device

A technology for grinding and grinding surfaces, applied in the direction of grinding/polishing equipment, grinding machines, abrasives, etc., can solve the problems of quality decline, grinding, large free length, etc., and achieve the effect of improving the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

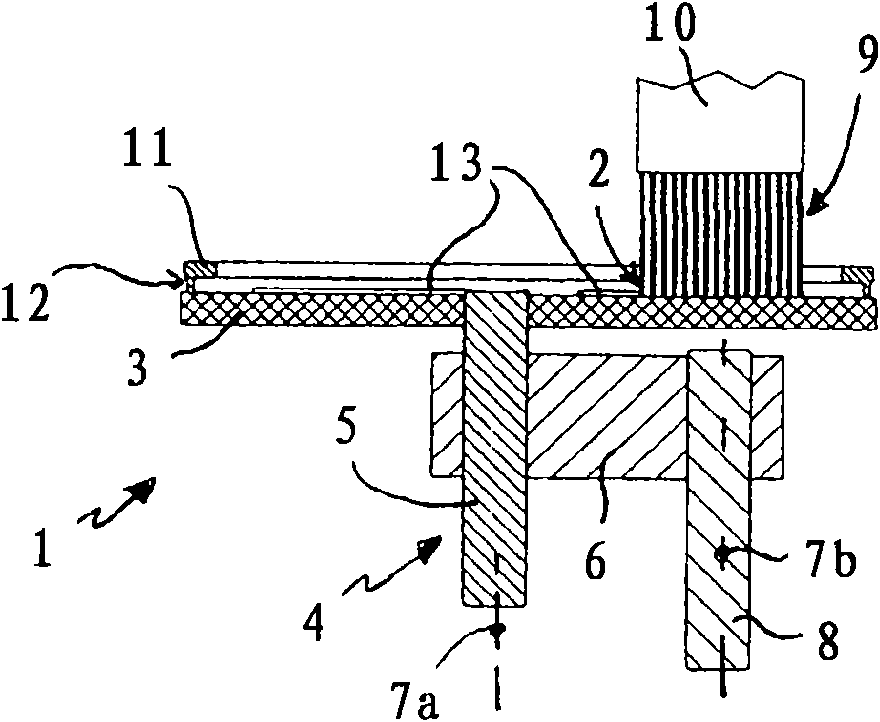

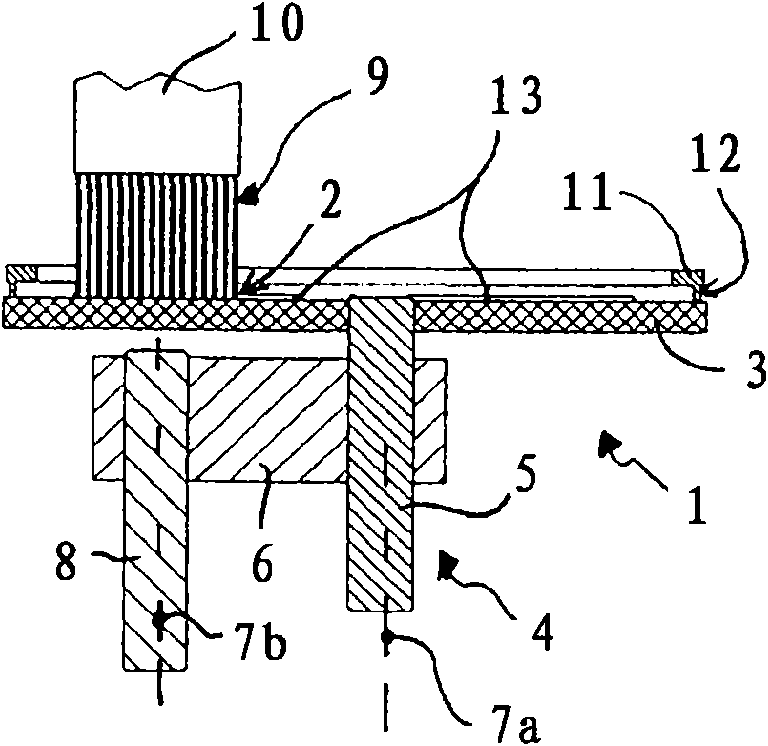

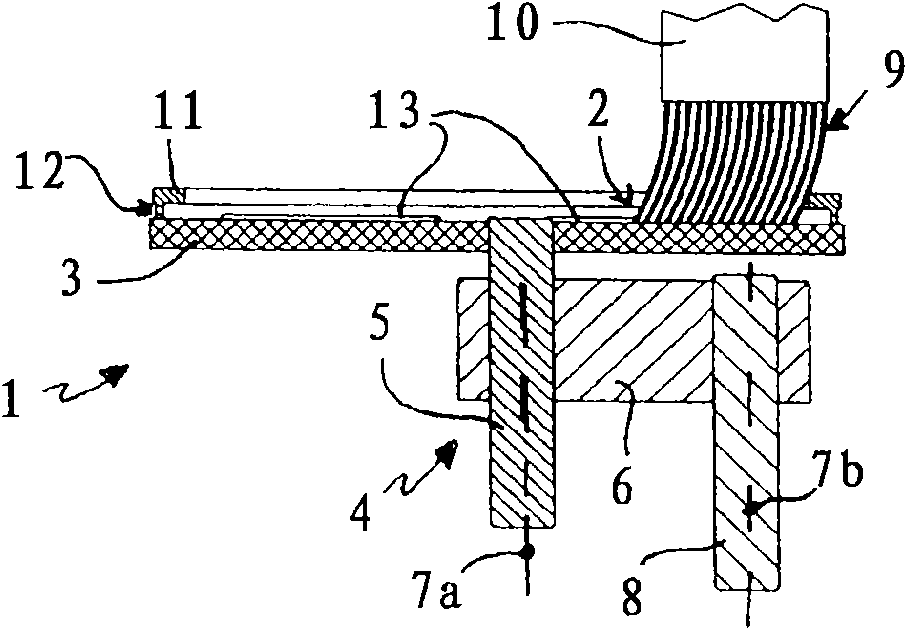

[0021] As shown in the drawing, the grinding device designated by reference numeral 1 for grinding bristle ends 2 has a grinding wheel 3 which is connected to a rotary drive 4 and is rotatably mounted.

[0022] The grinding wheel 3 is rotatable about a first axis of rotation 7 a via a flexible shaft 5 , which is rotatably mounted in an eccentric element 6 . The eccentric element 6 is in turn fixedly connected to a further shaft 8, which is driven by a drive (not shown), such as a servo motor, and is rotatable about the second axis of rotation 7b.

[0023] The flexible shaft 5 directly connected to the grinding wheel 3 rotates at a high speed so that the bristle ends 2 can be well ground; The two shafts 5 , 8 can also be connected to one another via a transmission not shown in the figure, so that only a single common drive motor is required for the two shafts 5 , 8 .

[0024] From Figure 5 and 6 In particular, it can be seen that the grinding wheel 3 is connected eccentrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com