Method for separating and purifying ellagitannic acid in raspberry

A technology for the separation and purification of ellagitannin, which is applied in the field of separation and purification of ellagitannin in Rubus, can solve the problems that the product content is greatly affected, the separation and purification cannot be achieved, and there are no reports, so as to improve the drug Good effect, economic and social benefits, and high separation purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

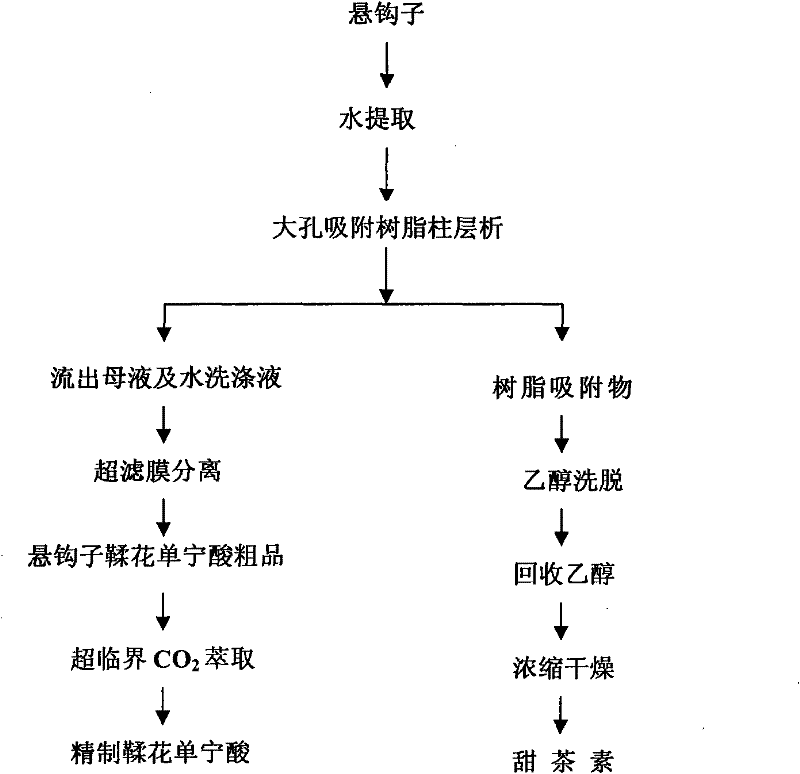

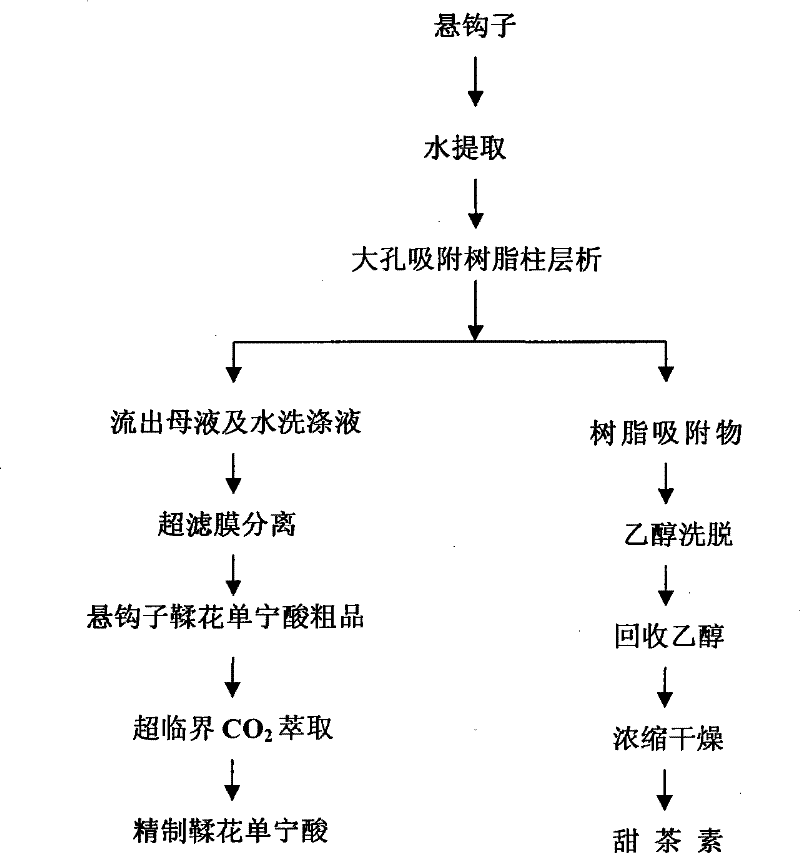

Image

Examples

Embodiment 1

[0026] In the stainless steel reaction kettle, add the dried leaves of the former drug Rubus in parts by weight as 50 parts, water as 600 parts and protective agent sodium pyrosulfite as 6 parts, boil and keep warm for 1 hour, filter, and the extract is for subsequent use; Continue to add 600 parts of water and 6 parts of protective agent in parts by weight to the slag, boil and keep warm for 1 hour, filter, and combine the secondary extract; pass the cooled extract through a DM101 macroporous adsorption resin column, and wash with water When it is clear, the mother liquor and washing liquid are combined for subsequent use; the mother liquor and washing liquid are ultrafiltered through an organic membrane with a molecular weight of 30,000 Daltons used in the first pass, and then the organic membrane molecular weight used is 1,000 Daltons for the second organic filtration. Membrane ultrafiltration is concentrated, and the retentate is concentrated and dried to obtain a crude pro...

Embodiment 2

[0029] Adding the whole plant of the former drug Rubus in parts by weight in the stainless steel retort is 55 parts, water is 650 parts and protective agent sodium pyrosulfite is 7 parts, boils and keeps warm for 1.5 hours, filters, and the extract is for subsequent use; Continue to add 650 parts of water and 7 parts of protective agent to the slag, boil and keep warm at 0.5, filter, and combine the secondary extract; pass the cooled extract through DM101 macroporous adsorption resin column or similar type packing The column is washed with water until it is clear, and the mother liquor and washing solution are combined for subsequent use; the mother liquor and washing solution are passed through the first ultrafiltration with an organic membrane molecular weight of 20,000 Daltons, and then the organic membrane molecular weight used is 200 Daltons. The second organic membrane ultrafiltration is concentrated, and the retentate is concentrated and dried to obtain a crude product o...

Embodiment 3

[0032] In the enamel reaction tank, adding the dried leaves of the former drug Rubus in parts by weight is 45 parts, water is 550 parts and protective agent sodium pyrosulfite is 5 parts, boiling and insulating is 1 hour, filters, and the extract is for subsequent use; Continue to add 550 parts of water and 5 parts of protective agent to the slag, boil and keep warm for 1.5 hours, filter, and combine the secondary extract; pass the cooled extract through a DM101 macroporous adsorption resin column or similar models The packed column is washed with water until it is clear, and the mother liquor and water washing liquid are combined for later use; the mother liquor and water washing liquid are passed through the ultrafiltration of an organic membrane with a molecular weight of 26,000 Daltons used in the first pass, and an organic membrane with a molecular weight of 1,000 Daltons is used again. Carry out the organic membrane ultrafiltration concentration for the second time, obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com