Template unit for cast-in-place concrete wall and construction method thereof

A concrete wall and formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of affecting the quality of concrete molding and project cost, unstable construction quality, and low turnover times of formwork To achieve the effect of shortening the construction period, improving the quality of joints, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

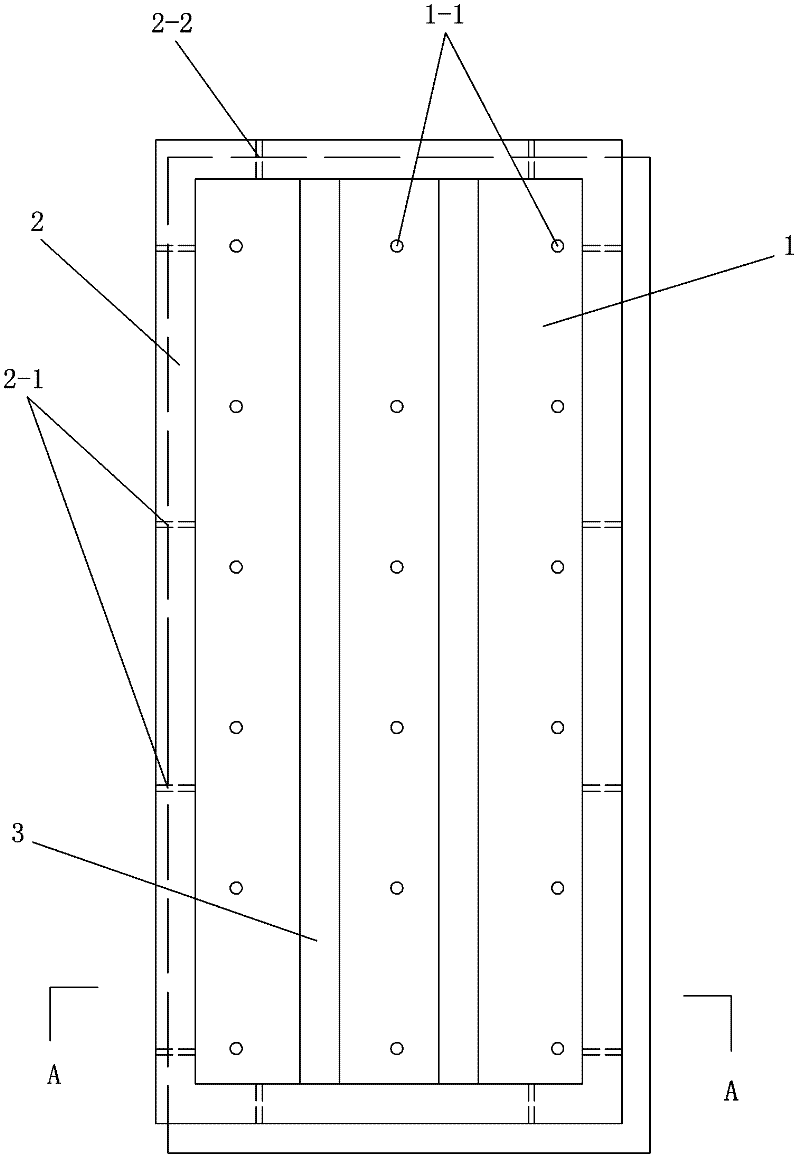

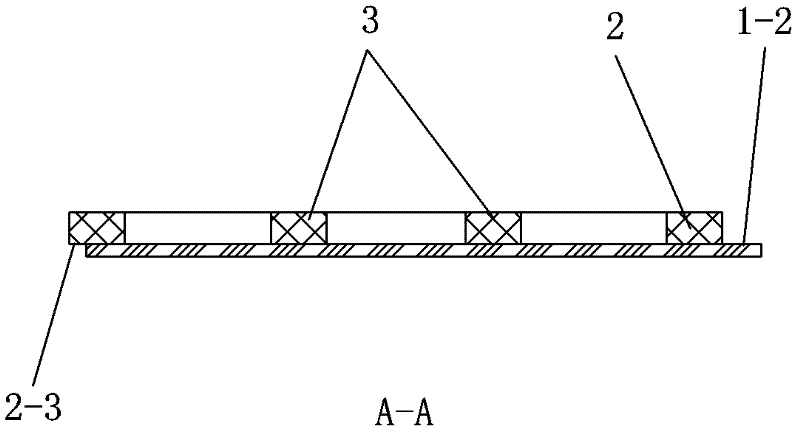

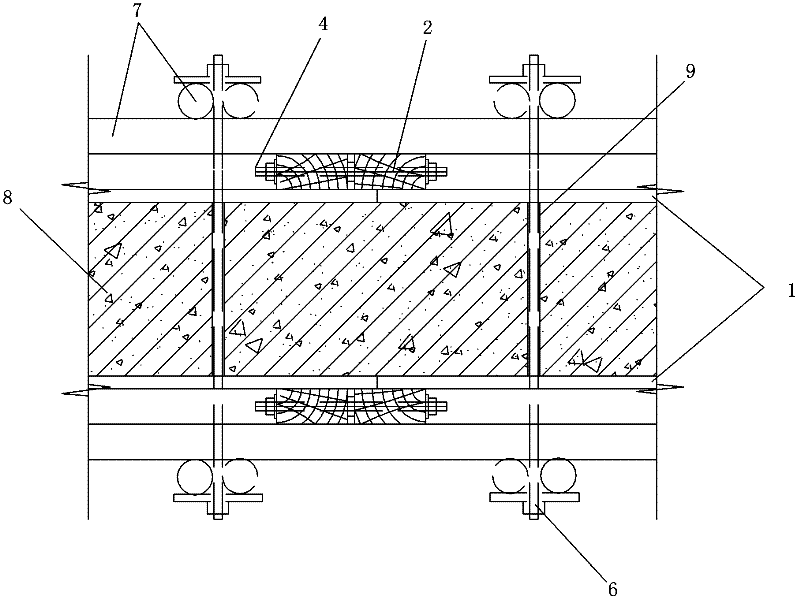

[0022] See Figure 1-4 , the formwork unit for the cast-in-place concrete wall of the present embodiment includes: a rectangular plywood 1 and splicing wooden frames 2 arranged on four sides of the plywood 1; Horizontal splicing bolt holes 2-1 are provided on the vertical frame of the frame 2, and vertical splicing bolt holes 2-2 are provided on the horizontal frame of the splicing wooden frame 2; the lower edge and the right edge 1-2 of the plywood 1 extend out of the splicing wooden frame 2. The upper and left edges 2-3 of the spliced wooden frame 2 extend out of the plywood 1 .

[0023] The plywood 1 is also provided with a corrugated wood 3 fixed in the spliced wooden frame 2 . The six end faces of the plywood 1 are sealed with film. It is also possible to seal all the processing places of the plywood 1 with novolac varnish. The width of the lower edge and the right edge 1-2 of the plywood 1 extending out of the splicing wooden frame 2 is 5-15mm larger than the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com