Continuously variable valve timing phaser

A valve timing and phaser technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve problems such as insufficient fuel combustion, difficult control of control mechanisms, heavy pollution, etc., to improve power and fuel economy , Improve torque and power, and fully burn gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

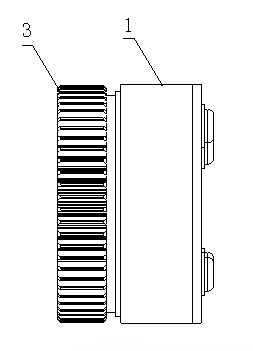

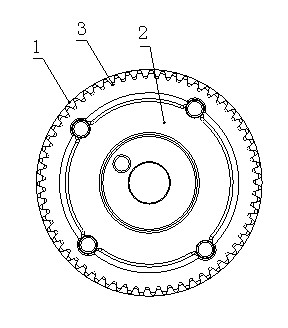

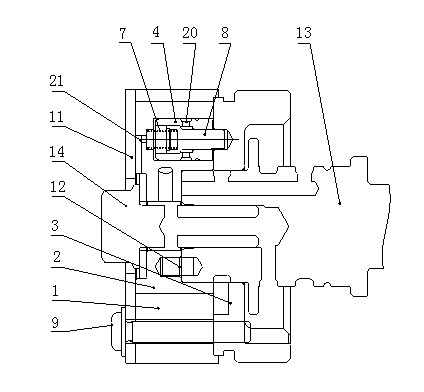

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , a continuously variable valve timing phaser, which is fixed on the camshaft 13 through pins 12 and mounting bolts 14, which includes a casing 1, an impeller 2, a sprocket 3, screws 9, a rear cover 11, a locking mechanism 18, The sealing assembly 19 and the locking mechanism 18 are pressed into the impeller 2 to form the impeller assembly. The impeller assembly is placed in the casing 1. The two ends of the casing 1 are sealed with the back cover 11 and the sprocket 3. The screw 9 passes through the back cover 11 and the casing 1 and then screwed. The sprocket 3 fixes the back cover 11, the impeller 2 is free to rotate in the closed space formed by the casing 1, the back cover 11 and the sprocket 3, grooves 25 are distributed on the casing 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com