Hydraulic valve mechanism of diesel engine

A technology of valve train and diesel engine, applied in the direction of machine/engine, non-mechanically actuated valve, mechanical equipment, etc., can solve the problems of valve noise, low intake and exhaust efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

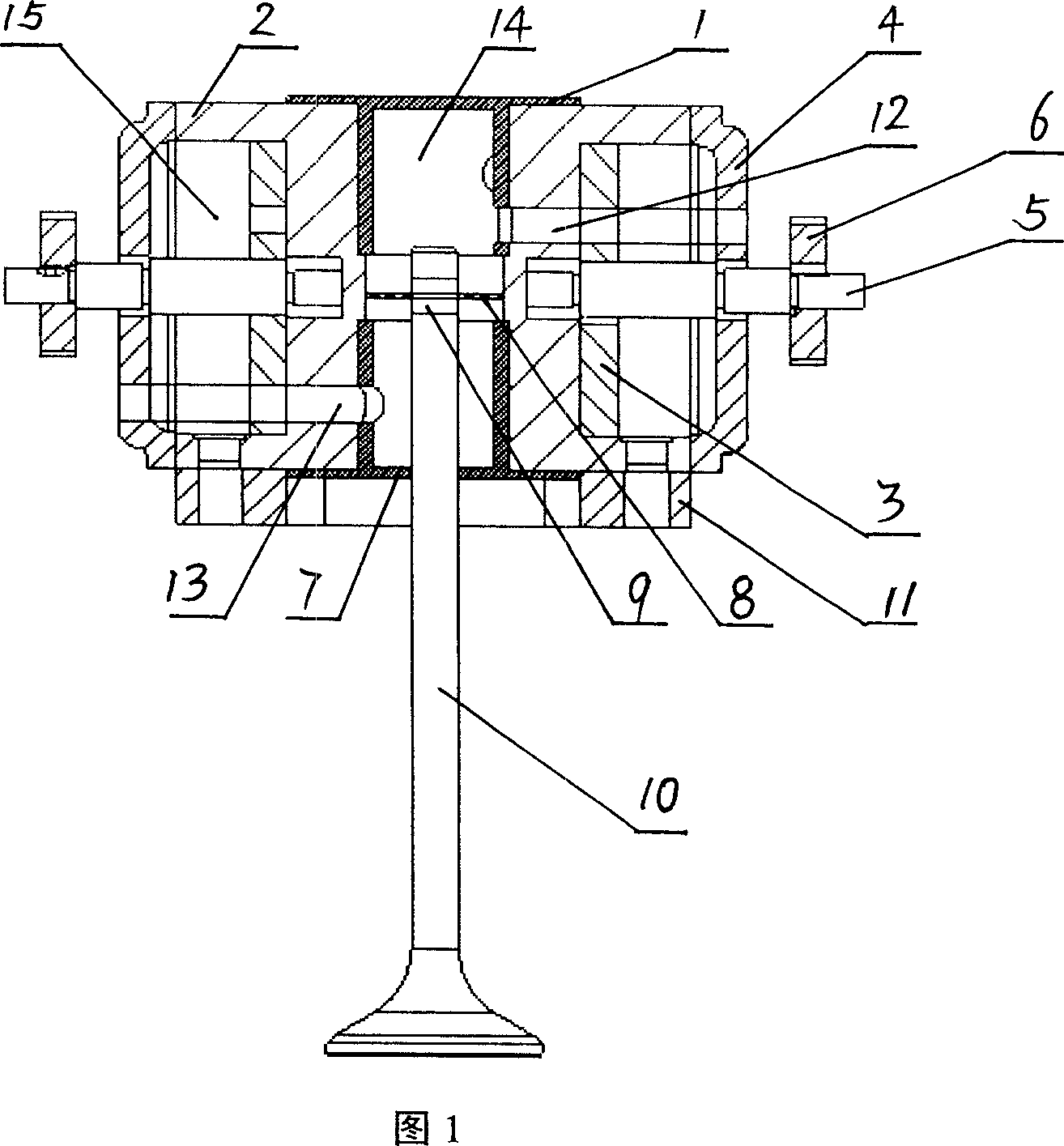

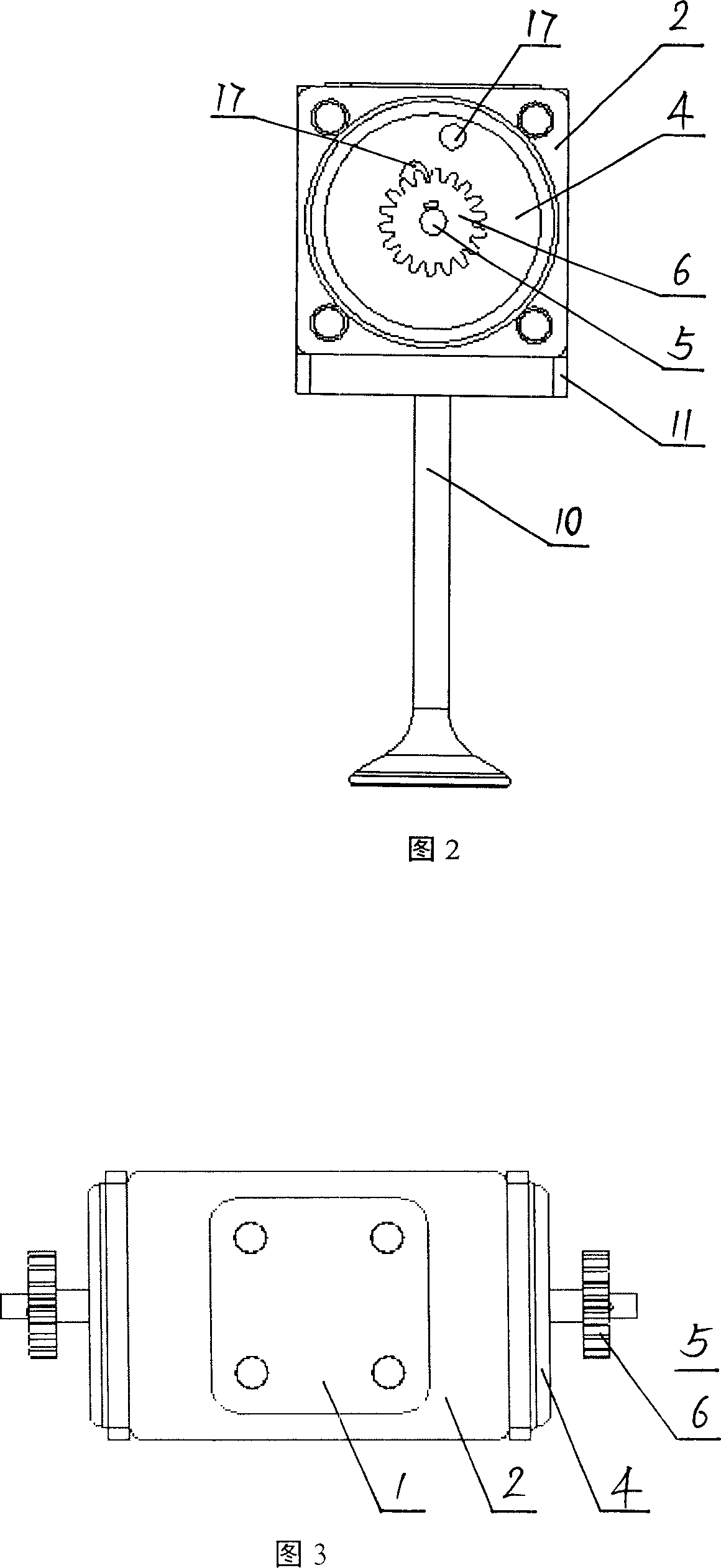

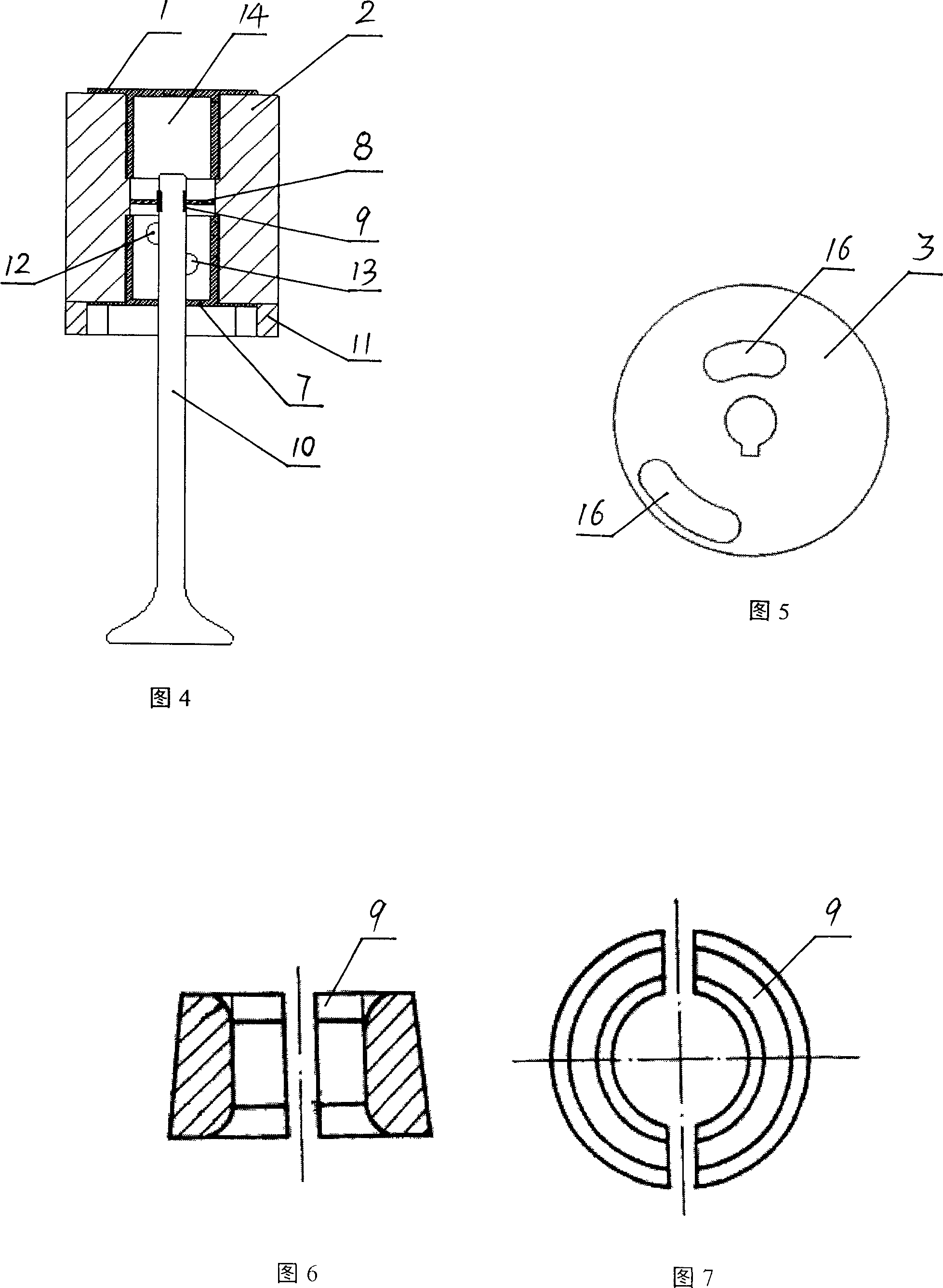

[0016] Referring to the accompanying drawings, the diesel engine hydraulically drives the valve distribution mechanism, including a hydraulic cylinder block 2, a valve 10, and a gear timing group. The hydraulic cylinder block 2 has a hydraulic chamber 14 that penetrates up and down and a timing disc chamber 15 that is symmetrically arranged on both sides of the hydraulic chamber 14 axially. Oil hole 13, oil return hole 12, the upper and lower ends of the hydraulic cylinder block 2 are sealed by the upper cylinder head 1 and the lower cylinder head 7, and the opposite inner ends of the upper cylinder head 1 and the lower cylinder head 7 have a hollow cavity communicating with the hydraulic chamber 14 , the cavity walls of the upper cylinder cover 1 and the lower cylinder cover 7 are provided with high-pressure oil inlet holes and oil return holes corresponding to the positions of the high-pressure oil inlet hole 13 and the oil return hole 12, and the upper cylinder cover 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com