Method for extracting features of crack acoustic emission signal of drawing part

An acoustic emission signal and feature extraction technology, which is applied in the direction of using the acoustic emission technology for material analysis, processing the response signal of the detection, etc. Network identification speed and accuracy, etc., to achieve the effect of fast calculation speed, improve diagnosis efficiency, and shorten diagnosis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

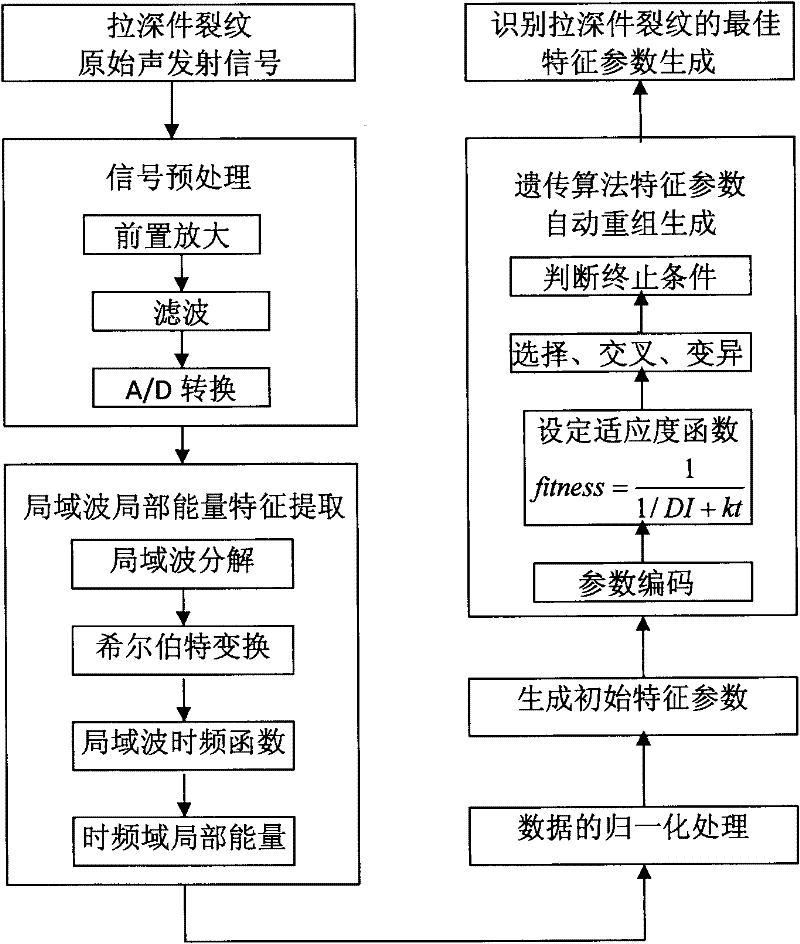

[0012] Such as figure 1 As shown, in the present invention, the original signal of the crack acoustic emission of the deep-drawing part is preprocessed in the computer, and then the local energy feature of the local wave is extracted, and finally the characteristic parameters of the genetic algorithm are automatically recombined to obtain an effective identification drawing. The optimal characteristic parameters of the acoustic emission signal of the crack in the deep part are specified as follows:

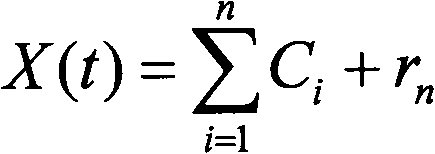

[0013] In the computer, the original acoustic emission signal of cracks in the deep-drawing parts is firstly processed through signal preprocessing, and the signal preprocessing includes pre-amplification, filtering, A / D conversion and other pre-processing in turn. Aiming at the acoustic emission characteristics of cracks in deep-drawing parts, a resonant sensor with a bandwidth of 100KHz-300KHz is selected to capture the corresponding acoustic emission signals when cracks occur. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com