Gate driving circuit on liquid crystal panel

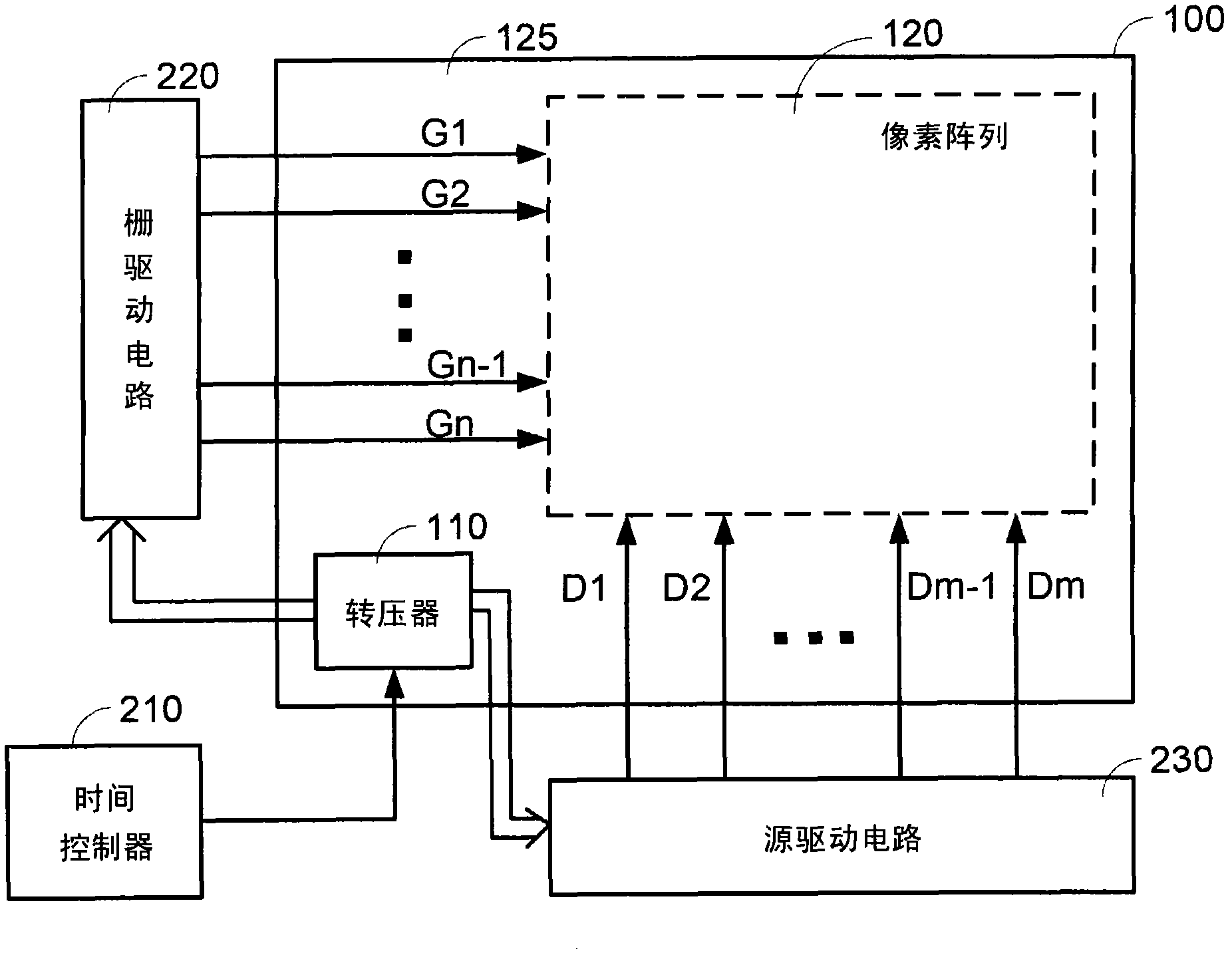

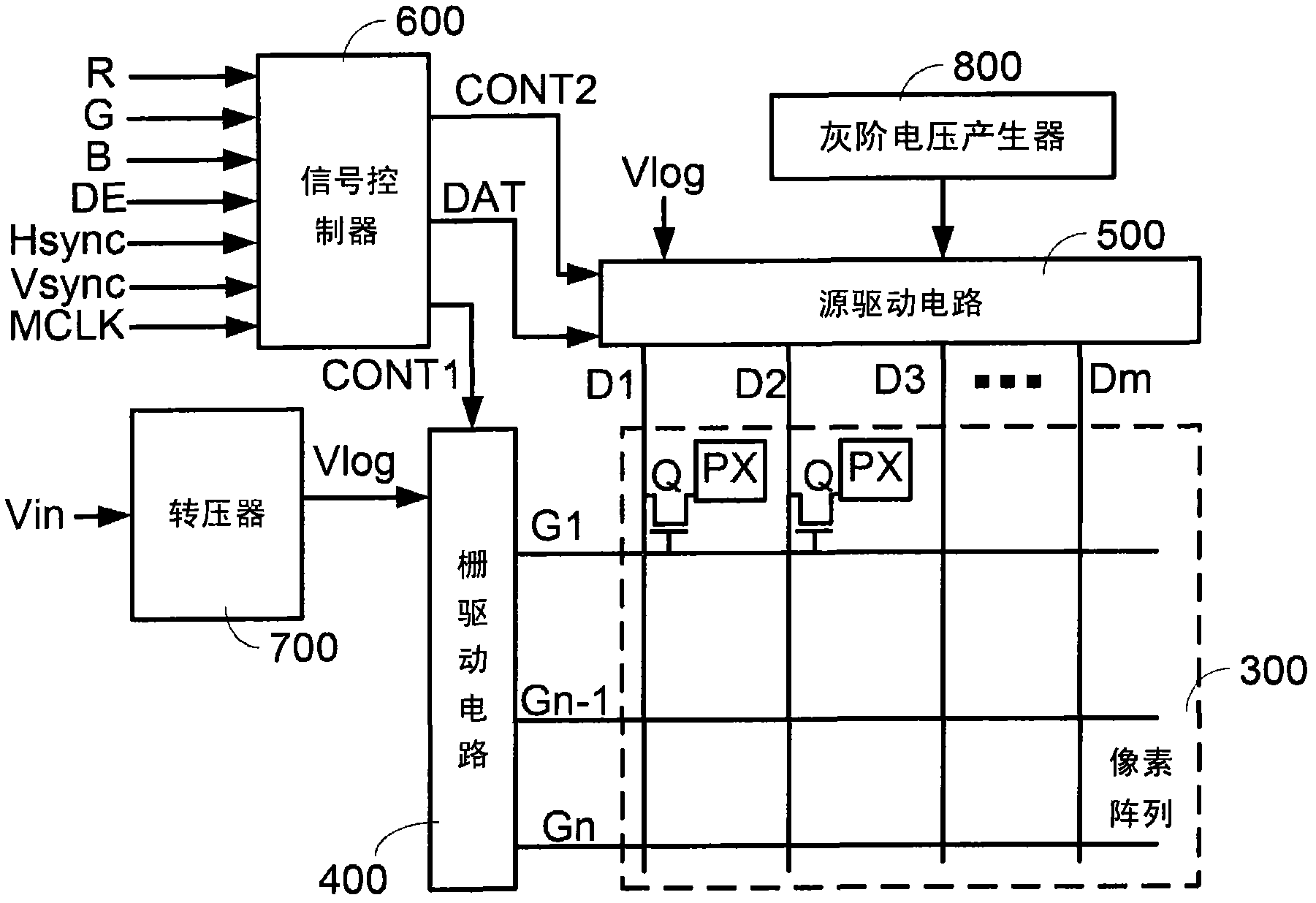

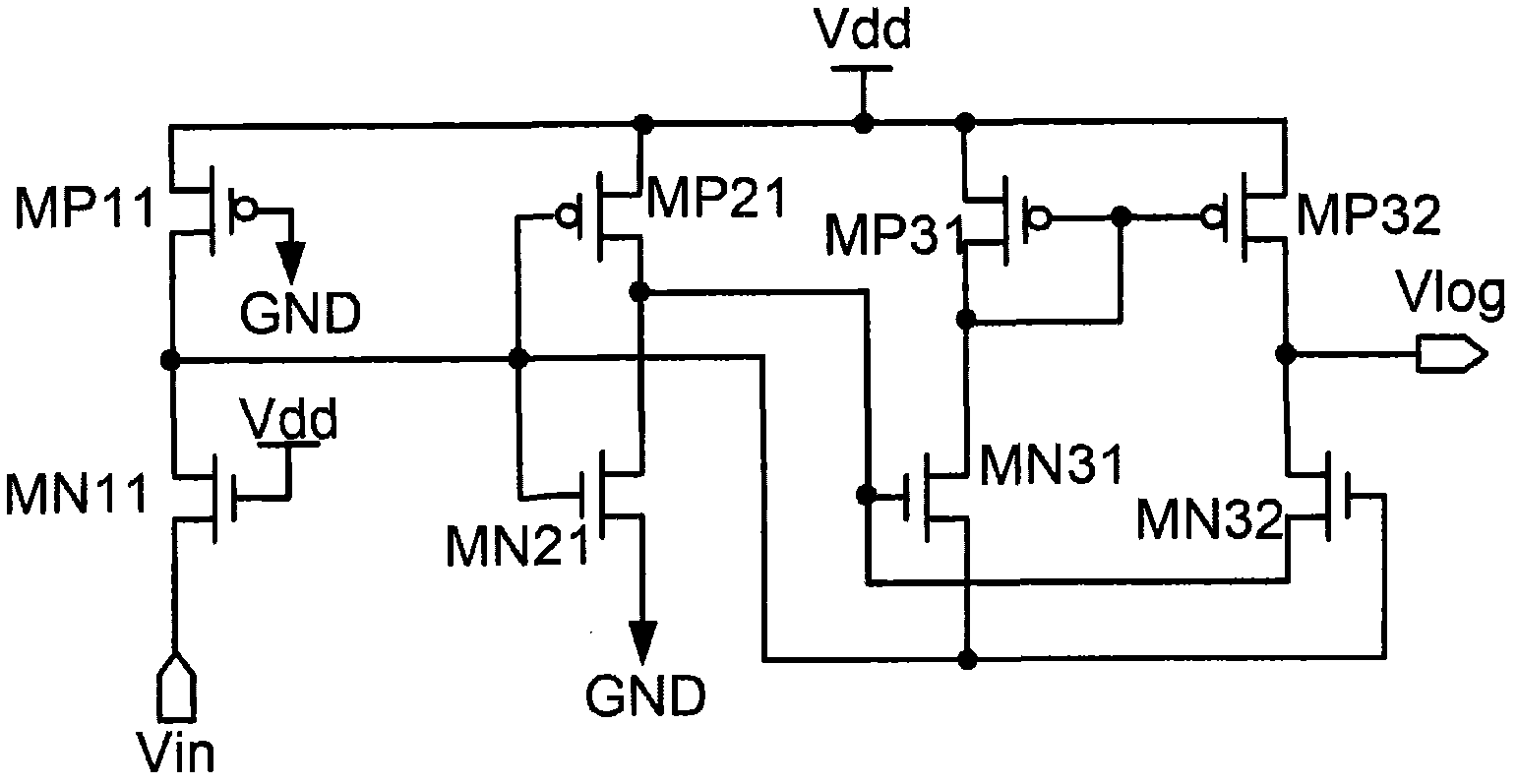

A technology for gate driving circuits and driving transistors, which can be used in instruments, static indicators, etc., to solve problems such as high power, complicated circuit design and fabrication, and high-level voltage Vlog attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0052] According to the first embodiment of the present invention, the shift register in the gate drive circuit integrates the shift unit 910 and the transformer 920, and the transformer is located in the last stage of the gate drive circuit, so it can effectively Power loss is reduced, and distortion of gate drive signals is prevented. Furthermore, the transistors in the present invention are all N-type thin film variable crystals of the same type, so the design and manufacture of the gate driving circuit can be greatly simplified.

[0053] Please refer to Image 6 , which shows the second embodiment of the gate driving circuit on the GOA panel of the present invention. The gate driving circuit 950 includes a plurality of shift registers 951˜95n+1. The first shift register 951 generates a first gate driving signal G1 and a first secondary notification signal NS1 after receiving the start signal START. After receiving the first secondary notification signal NS1 , the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com