Photochromic printing process of real wax clothing material

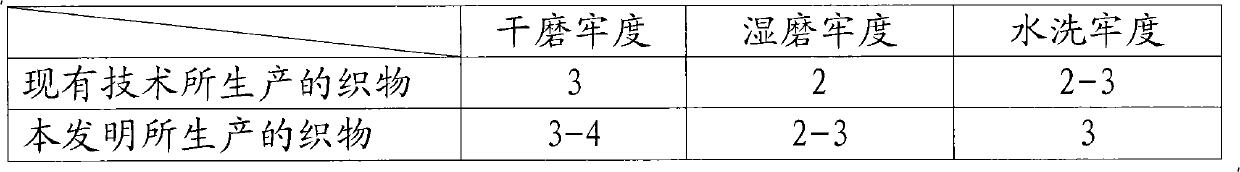

A printing process and clothing technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of poor dyeing coverage, single color of fabric, poor fastness, etc., achieve strong color contrast, high printing and dyeing quality, and ensure continuous uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

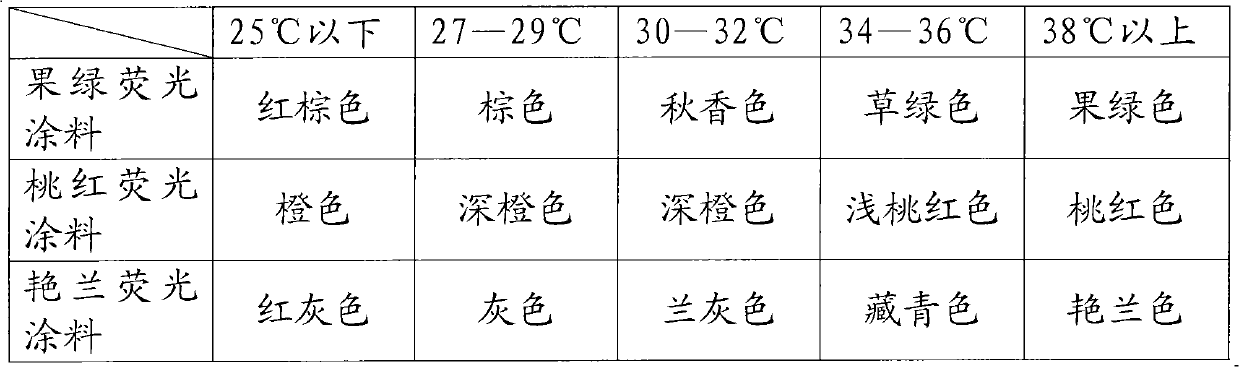

[0019] Take the 102609 pattern C24×2472×60 54” fabric produced by our company as an example, when the temperature is required to gradually rise from 25°C to 38°C, the printing color of the fabric will gradually change from dark green to reddish brown.

[0020] The technological process adopted is: seam turning → singeing → desizing → mercerizing → white cloth rolling → wax printing → Indian blue → wax removal → alkali washing and wax removal → rolling → printing → baking → tentering;

[0021] The raw materials of the used dyeing slurry in the printing step are:

[0022] Fluorescent paint: Fruit Green F4G, Dongguan Qicaihua Paint Technology Co., Ltd. 7%

[0023] Color-changing paint: 1-9UM, Shenzhen Caijia Technology Development Co., Ltd. 10%

[0024] Printing and dyeing adhesive: FS-468, 70% produced by Dandong Dyestuff Factory

[0025] Elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com