A kind of modified asphalt and its preparation method

A modified asphalt and thermoplastic technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems that the road performance cannot meet the higher road use requirements, the price remains high, and the production process is complicated, so as to reduce traffic. Accidents, less volatile matter, excellent road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A modified bitumen is prepared by the following method:

[0022] A. Material preparation

[0023] Coumarone resin and carbon five resin with a mass ratio of 3:2: 46 parts; rubber process oil: 14 parts; naphthenic oil: 10 parts; SBS: 14 parts; polypropylene wax: 0.02 parts.

[0024] B. Production steps

[0025] Add the above-mentioned amount of petroleum resin, rubber process oil, and naphthenic oil into an oil bath device kept at 155°C to 160°C, with stirring, until the petroleum resin melts, then add the above-mentioned SBS and polypropylene wax gradually. Continue to stir for 18min to 22min, while keeping the temperature of the oil bath at 155°C to 160°C.

[0026] After the material is fused evenly, it enters the shearing device, the shearing rate is controlled at 5500r / min-6000r / min, and the shearing time is 24min-27min. After shearing, the modified bitumen of the present invention is obtained.

[0027] The road performance indicators of the modified asphalt prep...

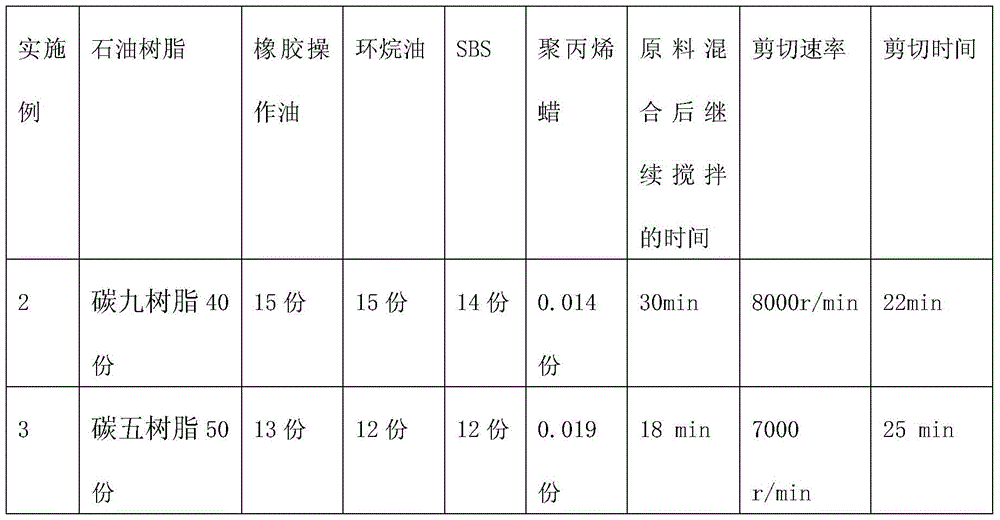

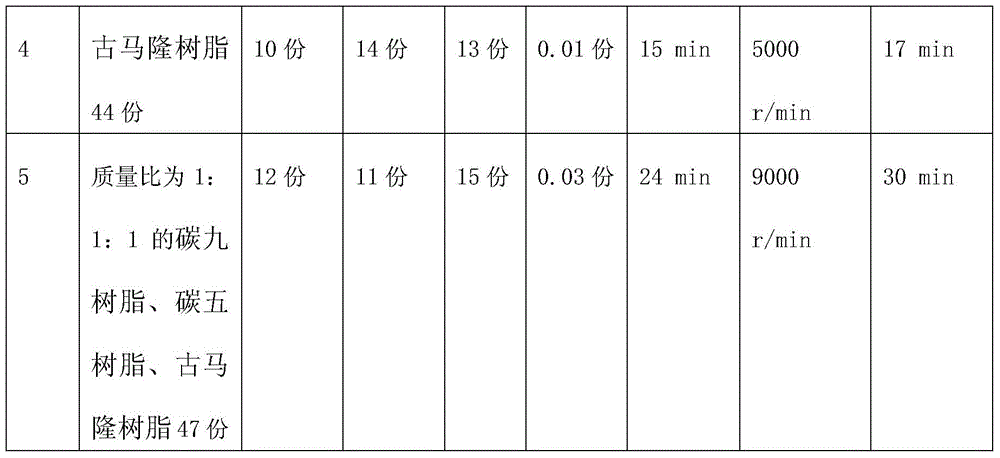

Embodiment 2--5

[0032] Carry out by following processing parameter, other are all identical with embodiment 1. The prepared modified asphalt has a penetration (25°C, 100g, 5s) (0.1mm) of 54.1-54.5, a ductility (5cm / min, 5°C) of 24.03-24.20, and a softening point (ring and ball method) of 65-68. , Flash point (COC) is 227-232, viscosity (135°C) is 1.624-1.634.

[0033]

[0034]

Embodiment 6

[0036] With the modified bitumen that embodiment 1~5 makes, make some Marshall test blocks according to " highway engineering asphalt and bituminous mixture test regulation ", experimental method is according to T0702-2011 middle bituminous mixture test piece preparation method (compaction method ), the Marshall sample block is made according to the standard sample in the regulations, the red coloring agent is added to the sample, and the height of the standard sample is 63.5mm±1.3mm. After the prepared sample was placed in the mold stably for 24 hours, the standard Marshall test piece was obtained. Continuously observe, monitor the color change, and put it into -18°C low temperature, normal temperature, and 120°C high temperature environment for 24 hours to observe the color change. Under low temperature and normal temperature, the color is stable and bright, and it becomes lighter in high temperature environment. After research, it is found , the phenomenon of lightening of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com