Ultra-thin stone heat insulation decorative plate with built-in fast installing member

A technology of thermal insulation decorative panels and installation parts, which is applied in covering/lining, construction, building construction, etc., to achieve the effects of safe use, cost reduction, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

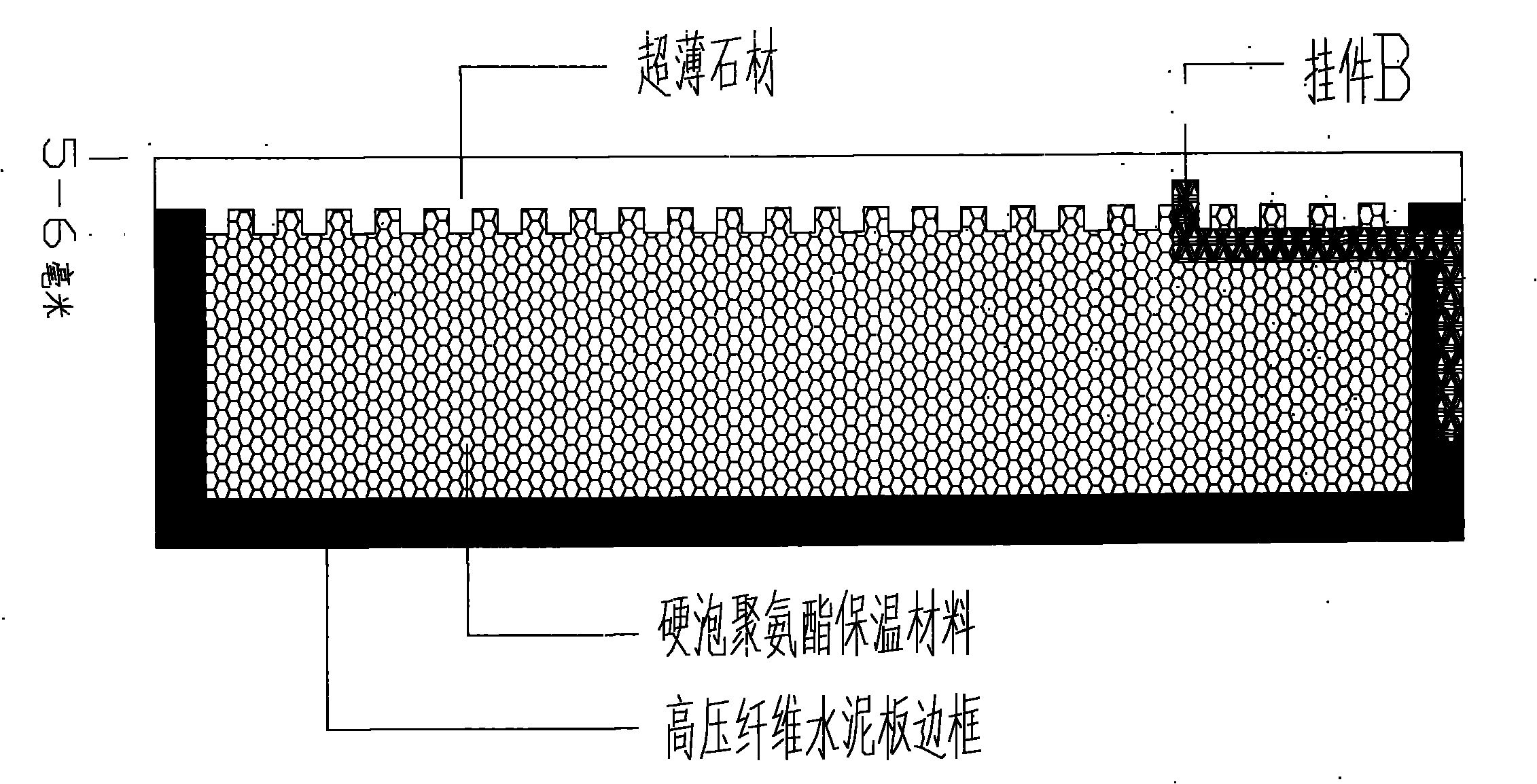

[0006] The first step is to cut the natural stone into ultra-thin stone with a thickness of 5-6mm.

[0007] The second step is to open the dovetail groove on the back of the ultra-thin stone, and process the rear wheel one centimeter around the back of the thin plate to a uniform thickness of 5*10.

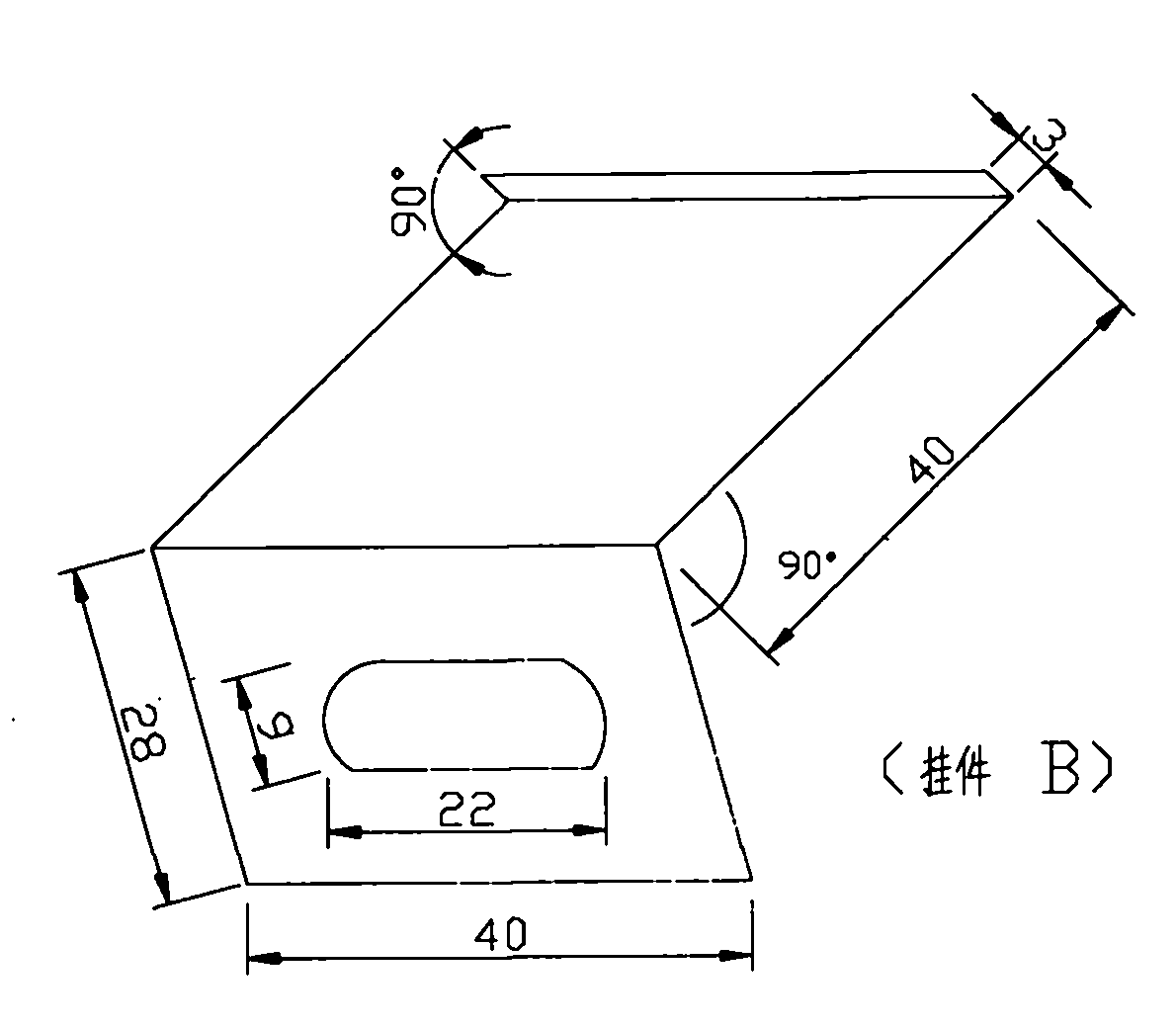

[0008] The third step is to paste and install the pendant B on the back of the ultra-thin stone.

[0009] The fourth step is to put the ultra-thin stone finished in the first, second and third steps into the mold.

[0010] The fifth step is to put the processed high-pressure fiber cement frame and back plate on the back of the ultra-thin stone around the mold. One side has a polyurethane insulation filling hole with a diameter of 25 mm.

[0011] The sixth step is to inject polyurethane insulation material and take it out after molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com