Construction Technology of Prestressed Channel Making and Positioning in Post-tensioned Prestressed Beam

A technology of prestressed beams and construction technology, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of difficult to meet the requirements of prestressed channel positioning accuracy, low steel binding accuracy, and unstable steel reinforcement. To achieve the effect of reducing the amount of steel bars, improving the accuracy, and improving the construction efficiency and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

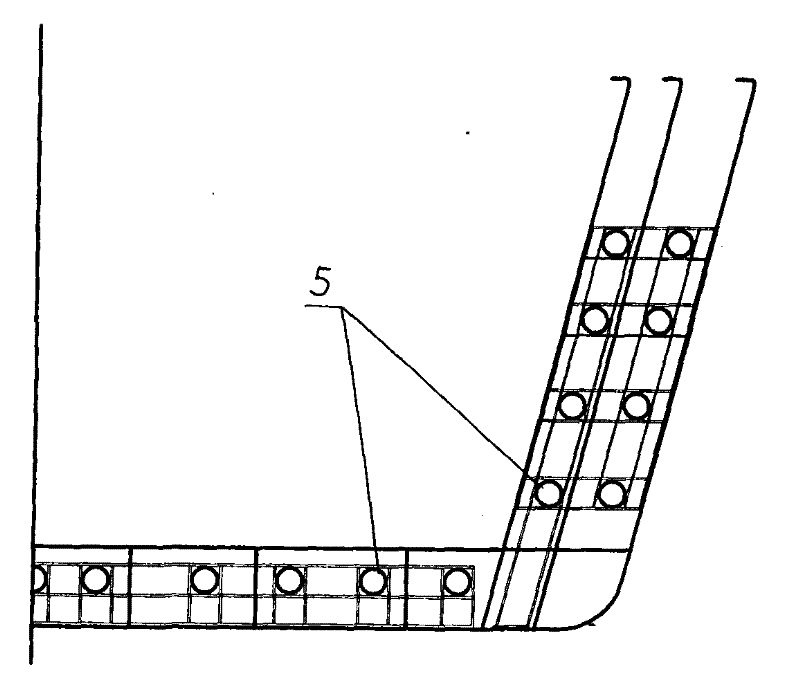

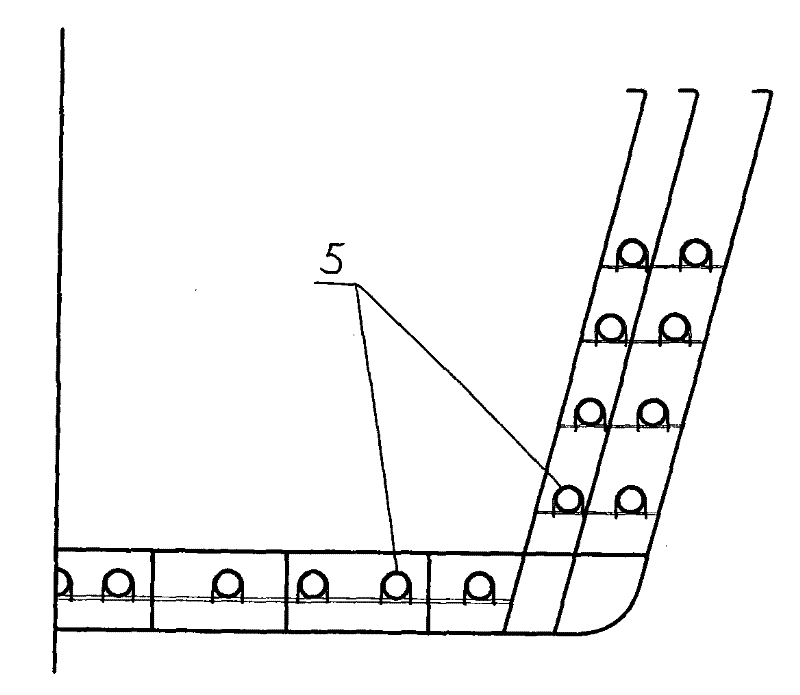

[0023] figure 1 It is an integral grid steel bar positioning net for the positioning of prestressed tunnels in the conventional method, and its steel bars are densely arranged, while the construction technology of the present invention uses positioning ribs for positioning. Therefore, from figure 1 , figure 2 It can be seen from the comparison that this construction technology significantly reduces the amount of steel bars compared with the conventional method.

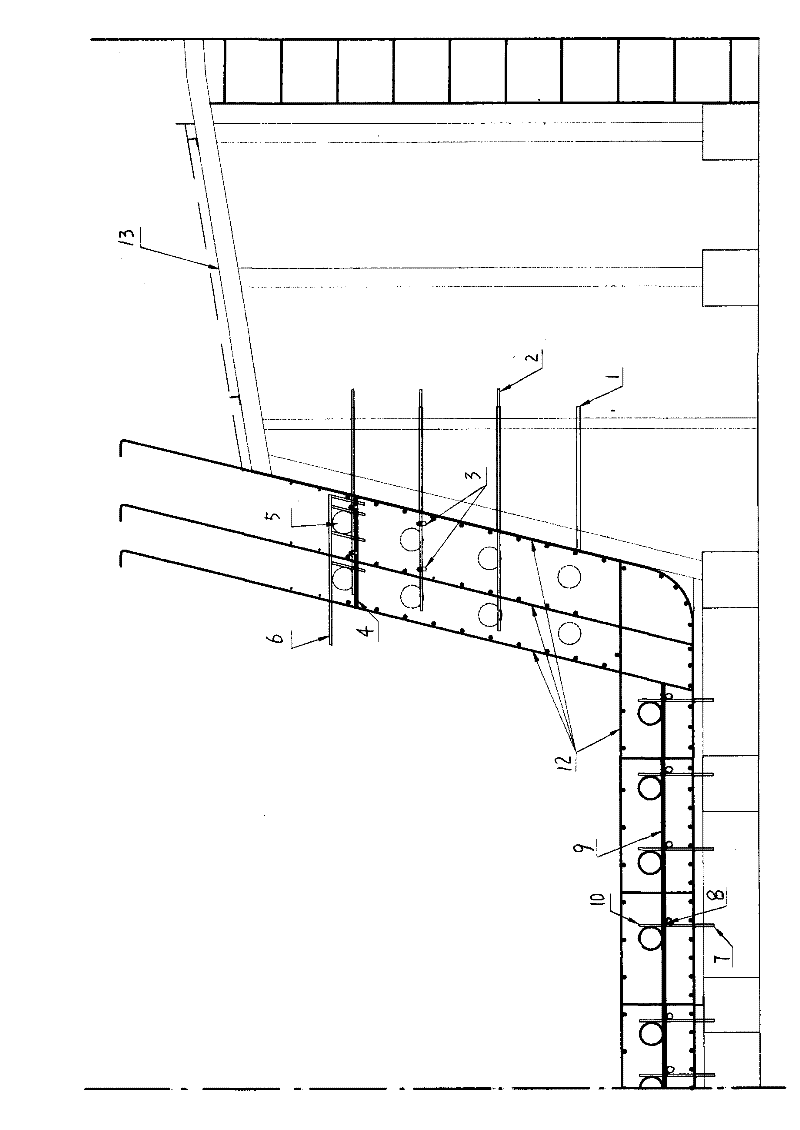

[0024] Reference to the construction technology of the prestressed channel hole making and positioning of the post-tensioned prestressed beam of the present invention image 3 , Figure 4 shown, including the following steps:

[0025] a. According to the position coordinate table of the prestressed reserved hole, process and manufacture the horizontal positioning caliper 6 of the web hole and the vertical positioner of the bottom plate hole. The vertical locator of the bottom plate hole is fixed with a vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com