Hole driven type horizontal directional drilling reverse circulation hole dilating drill

A horizontal directional drilling and reaming drill bit technology, which is applied in directional drilling, driving devices for drilling in boreholes, drill bits, etc., can solve problems such as greater influence on hole wall stability, changes in drilling shape, and large reaming torque , to achieve the effect of reducing accidents in the hole, lowering requirements, and improving stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

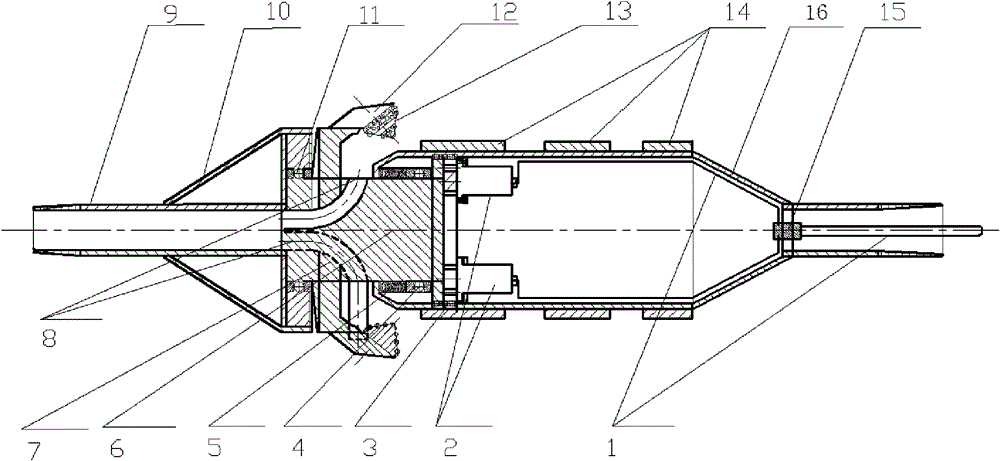

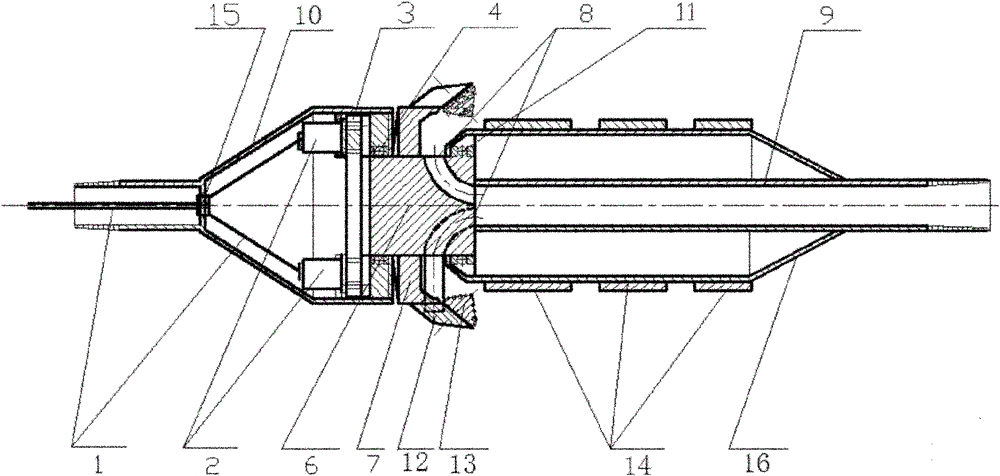

[0022] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

[0023] Such as figure 1 , figure 2 As shown, the main components of the in-hole driving type horizontal directional drilling reverse circulation reaming drill provided by the present invention are a drill body and a power drive device, and the insides of the drill cone 10 and the pen-like cone 16 of the drill body are hollow cavities body, the pen-shaped cone head 16 is provided with protective spokes 14, the middle part of the transmission shaft 6 in the power drive device is provided with a turntable 7, the cone seat 12 with the cone 13 is installed on the turntable 7, the tail of the drill cone 10 The end is installed on the rear end of the transmission shaft 6 through the thrust bearing b11, the tail end of the pen-shaped cone head 16 is installed on the front end of the transmission shaft 6 through the thrust bearing a4, and the motor 2 in the power drive devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com