Test instrument of flame sensitivity of loading material for initiating explosive device

A flame sensitivity and pyrotechnic technology, applied in the field of pyrotechnics, can solve the problems of blind spot in observation, blown resistance wire, poor flame height adjustment accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

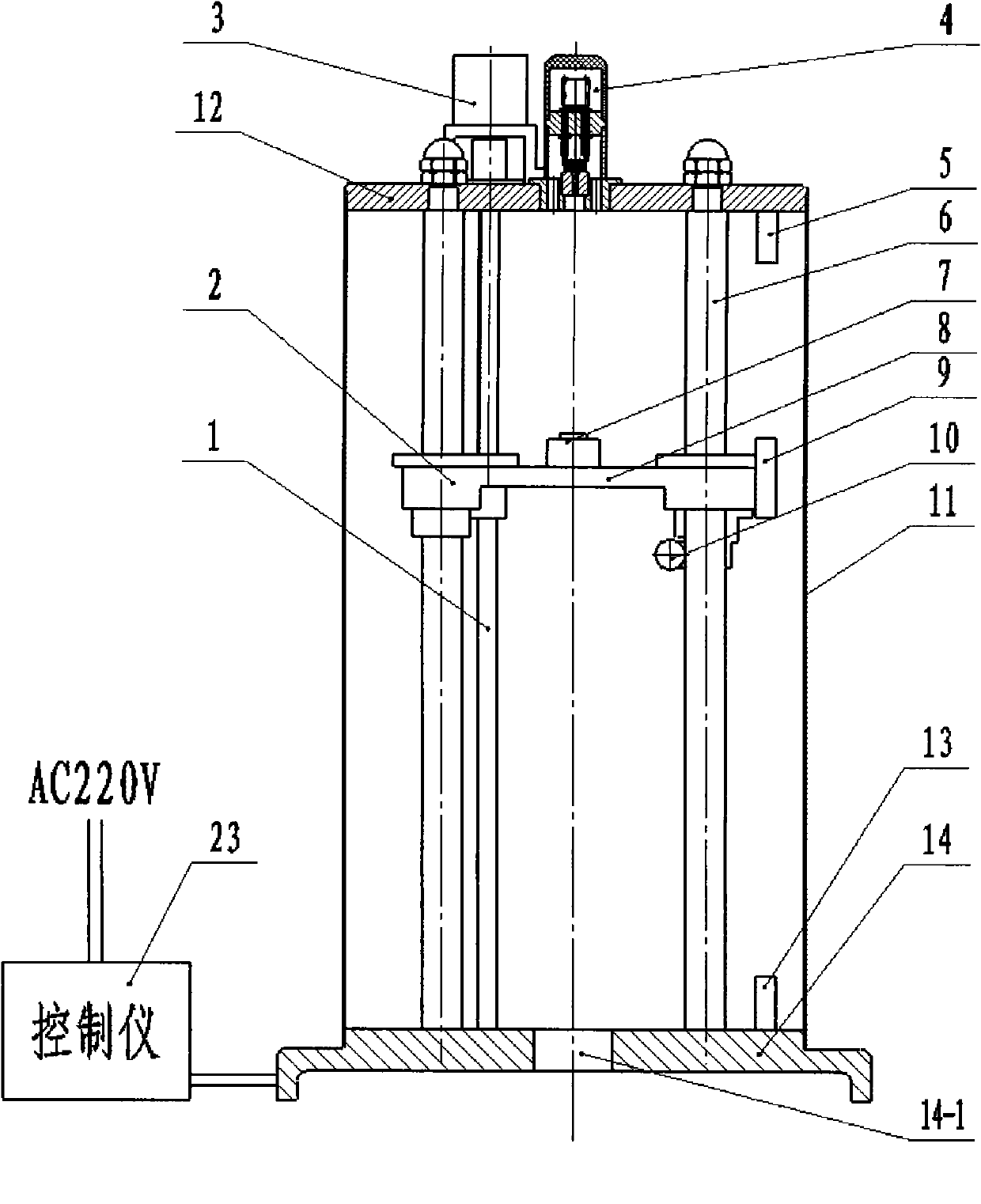

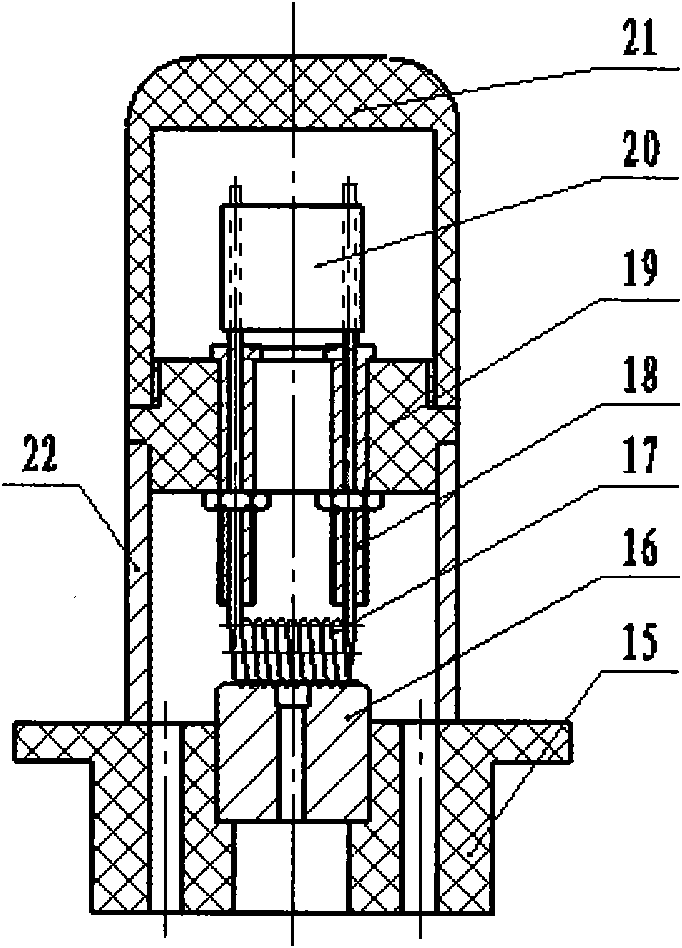

[0017] Such as figure 1 As shown, the preferred embodiment of the flame sensitivity instrument of the present invention includes a height adjustment device comprising a ball screw pair 1, a stepping motor 3, two ball guide bushes 2, an ignition device 4 and its thyristor ignition power supply, and a zero sensor 5. Two columns 6, sample mold 7, workbench 8, magnetic induction block 9, locking knob 10, shield 11, top cover with center hole 12, limit sensor 13, base 14 and controller 23 .

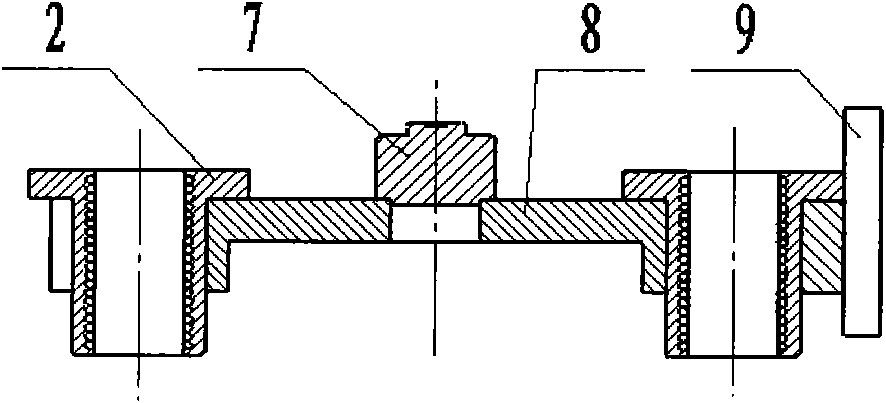

[0018] The two ball guide bushes 2 are correspondingly sleeved on the two columns 6 . Both ends of the two columns 6 are respectively fixed on the top cover 12 and the base 14 and are located symmetrically to the axis between the top cover 12 and the base 14 . The stepping motor 3 is installed on the top cover 12 . The workbench 8 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com