Hybrid fault diagnosis method based on qualitative signed directed graph in petrochemical process

A diagnostic method and fault technology, applied in the direction of instruments, control/regulation systems, general control systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

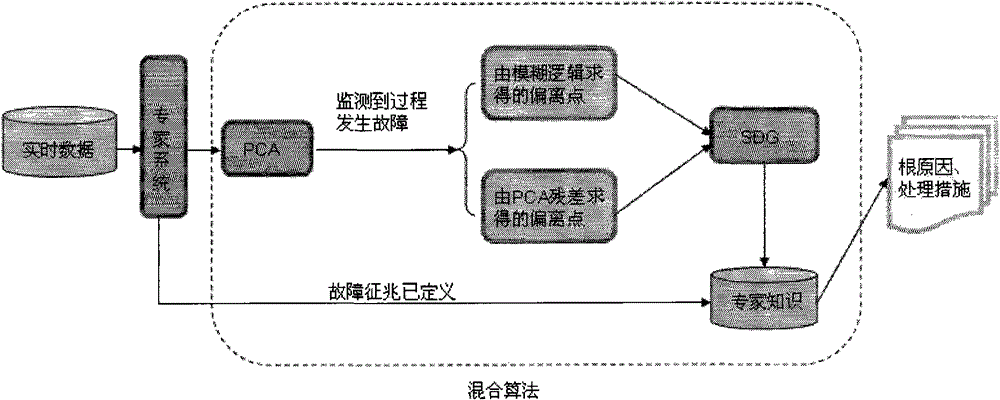

[0057] The present invention proposes a hierarchical diagnosis model that can be quickly established and expressed easily. The hierarchical model is composed of three layers, as shown in the attached figure 1 shown.

[0058] 1) The first layer is an expert system module

[0059] Extract the symptoms of the key nodes of the process flow (obtained based on operating experience) in the fault state, and store them in the expert knowledge base. During real-time monitoring, if the state of these nodes just falls into the state defined by the knowledge base, it can be concluded that it has entered a certain fault state, and the cause and consequence can be determined. In this way, the abnormal working condition management system can directly obtain the abnormal working condition conclusion of the monitored process. At this time, the software system does not need to enter the reasoning algorithm behind, which greatly reduces the reasoning time of the system.

[0060] 2) The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com