Transmission control mechanism of stirring system

A technology of transmission control and stirring system, applied in non-electric variable control, AC motor control, control system and other directions, can solve the problems of inability to control and optimize the stirring effect of vertical agitators, and there is no good solution, and achieve high reliability. , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

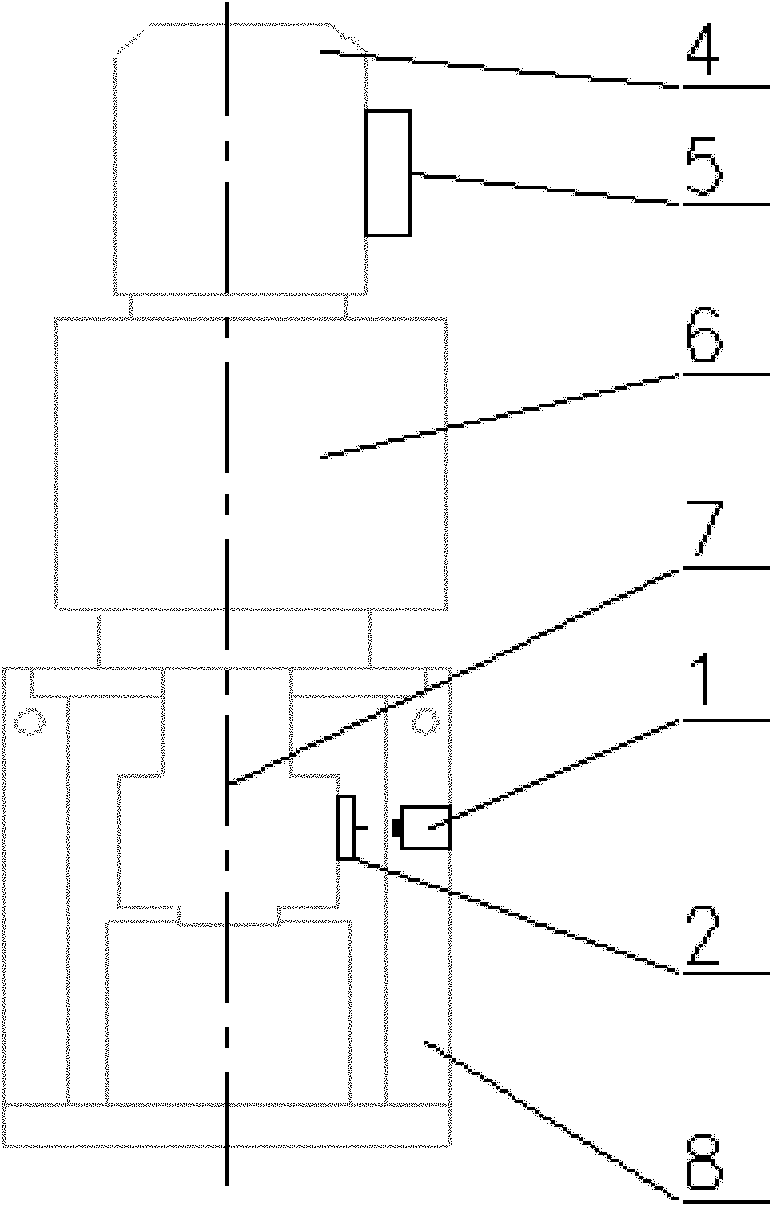

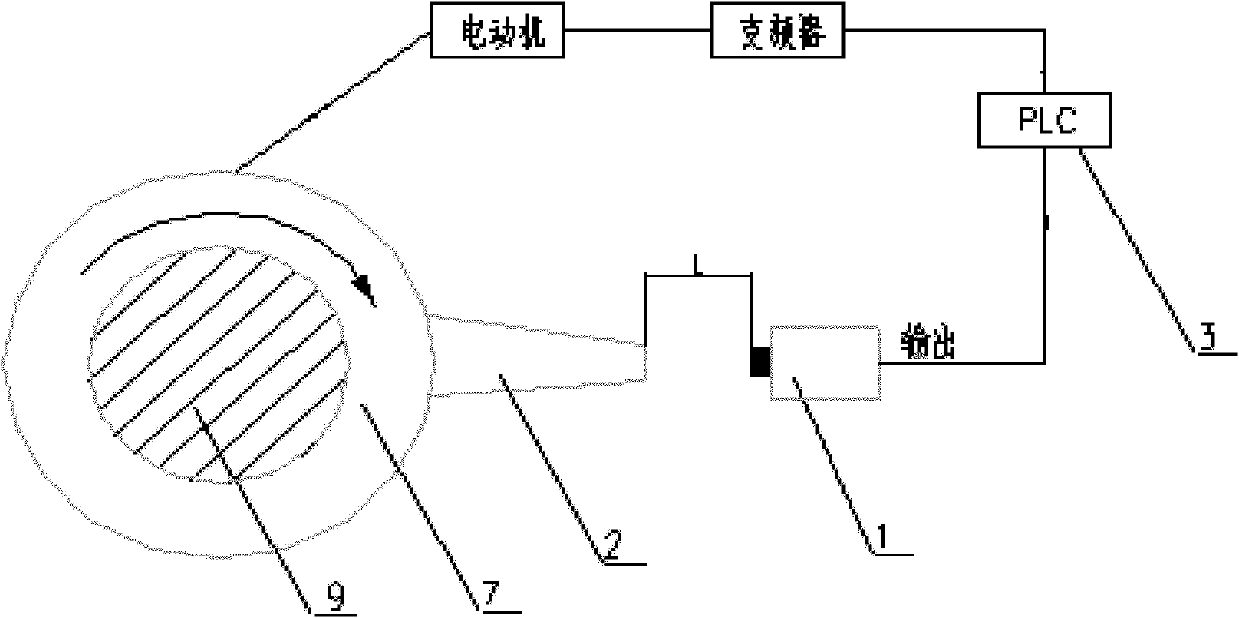

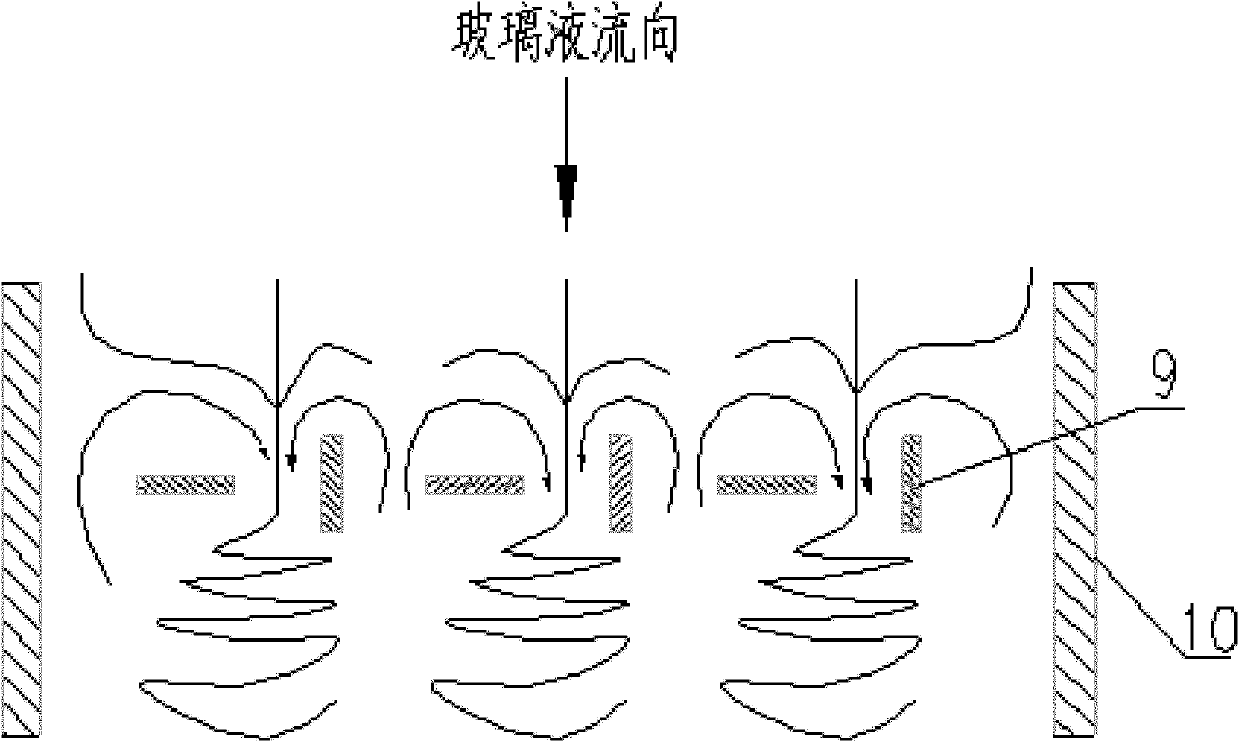

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail, the present invention is used for controlling the rotation speed and the phase angle of stirring blade, and its working environment is the kiln neck place (10) of float process, see image 3 . Initially, the six stirring blades (9) are staggered at 90° and arranged at the kiln neck (10). During operation, the adjacent stirring blades (9) turn in opposite directions, and the phase difference remains unchanged to ensure that the glass liquid entering the forming area All can be homogenized by stirring with a mixer. Such as figure 1 , 2 As shown: the proximity sensor (1) is installed on the bracket (8), the trigger (2) is fixed on the clutch (7), the motor (4) with the frequency conversion speed controller (5) is directly connected to the reducer (6) and The clutch (7) drives the stirring blade (9) to rotate once, and the proximity sensor (1) can receive a signal sent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com