Terminal of power semiconductor and manufacturing method of terminal

A technology for power semiconductors and manufacturing methods, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc. The effect of early breakdown, uniform distribution, and uniform distribution of the electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

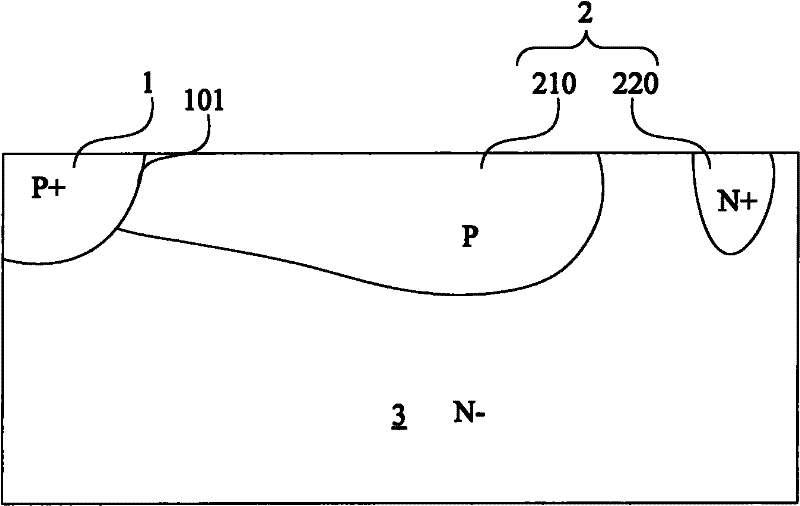

[0030] figure 2 It is a cross-sectional view of a power semiconductor with a terminal according to the first embodiment of the present invention, which is figure 1 Cut along the line AB. In this embodiment, the first conductivity type is N type, the second conductivity type is P type, and the terminal has a junction terminal extension region (JIE structure) doped with the second conductivity type (P type), and the junction termination extension region The doping thickness of the junction terminal extension region increases as the distance from the active region increases, and the doping concentration of the junction terminal extension region decreases as the distance from the active region increases. The doping thickness of the junction terminal extension region, that is, the depth of the JTE structure, is referred to as the JTE junction depth. Such as figure 2 As shown, the power semiconductor device having the terminal of the first embodiment of the present invention i...

Embodiment 2

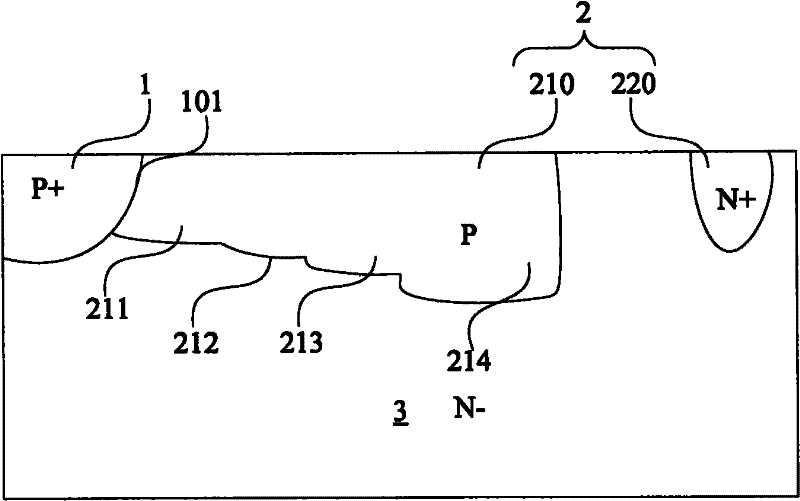

[0036] image 3 It is a cross-sectional view of a power semiconductor with a terminal according to the second embodiment of the present invention, which is figure 1 Cut along the line AB. Such as image 3 As shown, the difference between the technical solution of this embodiment and the technical solution of the first embodiment is that: the P-type JTE structure 210 is divided into several sections, and the JTE junction depths in each section are the same, but the JTE junction depths of all sections are gradually deepened, At the same time, the P-type JTE structure 210 also satisfies that the doping concentration in each section is the same, and the doping concentration in the section that is farther away from the main junction 101 is lower. The P-type JTE structure 210 in this embodiment is divided into four sections, namely the first section 211, the second section 212, the third section 213, and the fourth section 214. The JTE junction depths of all sections are increasi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap