Heater and heating furnace tube

A technology for heaters and heating furnaces, applied in the direction of furnace heating elements, etc., can solve the problems of heating furnace tubes and heaters that are prone to failure, and achieve the effects of not being easily deformed, ensuring the heating effect, and reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

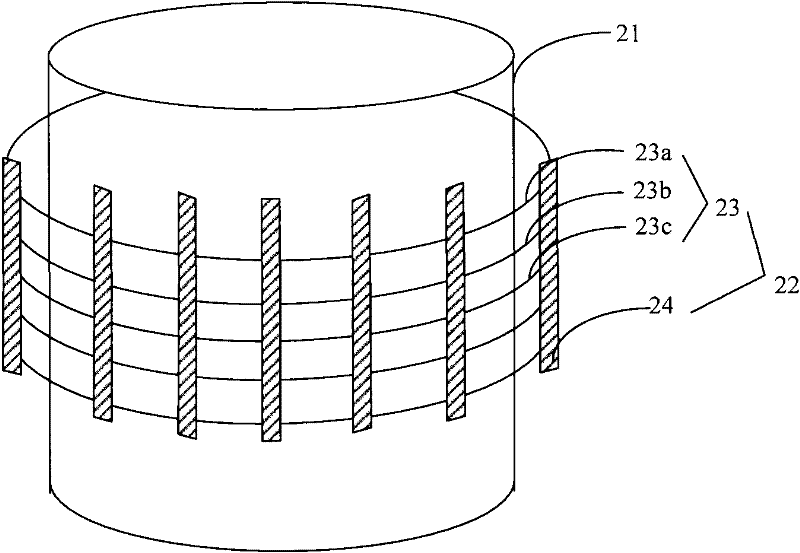

[0015] As can be seen from the background technology, in the prior art, the heater of the heating furnace tube usually includes many annular resistance wires 23a, 23b, 23c... and fixing pieces 24, and each fixing piece 24 connects all the resistance wires , so that the resistance wire is fixed, so that the heater 22 formed by the resistance wire and the fixing sheet is cylindrical; the heater 22 is arranged on the periphery of the cavity 21 . However, when the above-mentioned heating furnace tube is used for thermal oxidation process and chemical vapor deposition process, as the heating time increases, the heater often breaks down, which leads to failure of the heating furnace tube.

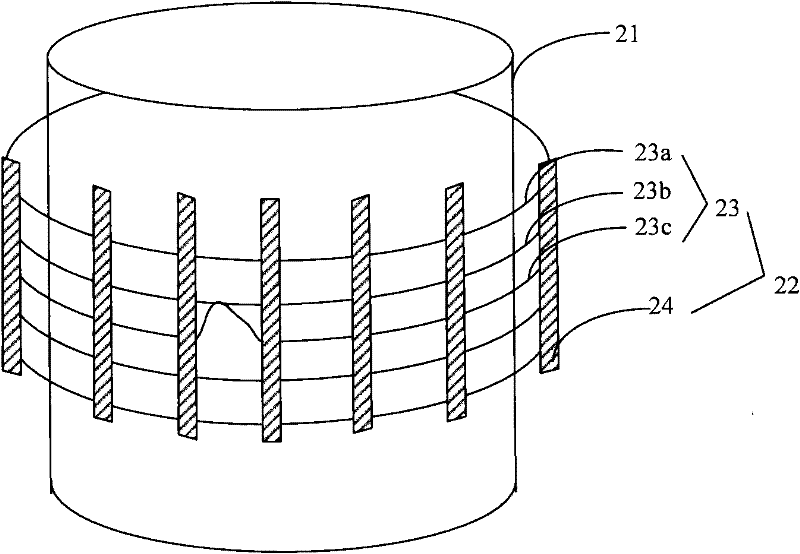

[0016] After research, the inventor thinks that the failure of the heater is due to the heating process, such as figure 2 As shown, the resistance wire will be deformed when it is heated. As the use time increases, the deformation of the resistance wire will become more and more serious. In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com