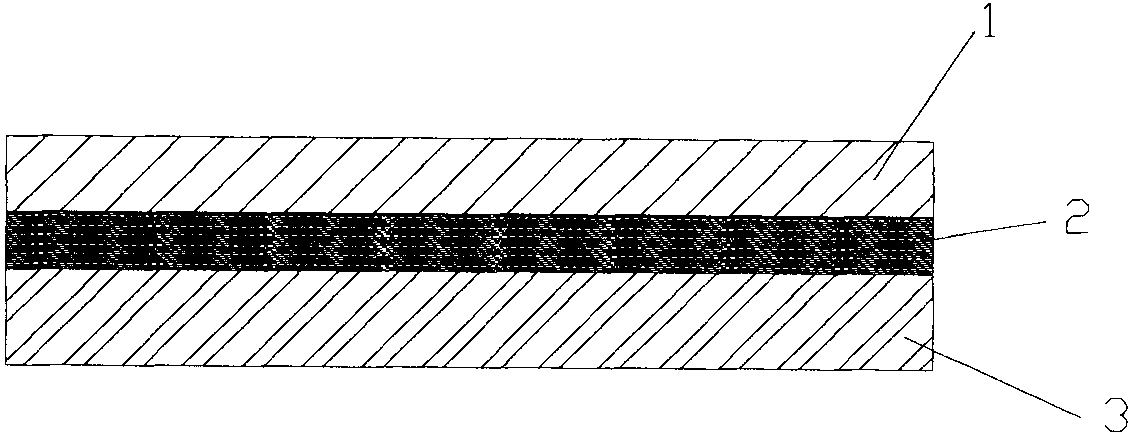

Double-sided elastic fabric

A kind of elastic fabric, double-sided technology, applied in the direction of clothing, clothing, protective clothing, etc., can solve the problems of physical health hazards, surface protrusions, allergies, peeling and other problems, achieve good air permeability and sweat absorption, good elastic distribution, improve The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The specific preparation process of the fabric is as follows:

[0015] a) prepare the middle layer, the middle layer is a blended fabric of natural cotton and polyester, and the blending ratio is 45% of natural cotton and 55% of polyester;

[0016] Concrete preparation process is as follows:

[0017] 1) First, the natural cotton strands are made into natural cotton strands through the processes of cleaning, opening, drawing, roving, spun yarn, winding, and twisting;

[0018] 2) Then, the polyester yarn is made into polyester yarn lines through loosening, carding, roving, spun yarn, and winding processes;

[0019] 3) Finally, the prepared natural cotton strands are used as the warp and the polyester yarn as the weft, and the middle layer fabric is made through a weaving process.

[0020] b) Prepare the upper elastic fabric layer yarn line, the material composition and percentage content of the upper elastic fabric layer are 10% spandex, 25% nano-bamboo charcoal fiber, ...

Embodiment 2

[0032] The specific preparation process of the fabric is as follows:

[0033] a) prepare the middle layer, the middle layer is a blended fabric of natural cotton and polyester, and the blending ratio is 40% of natural cotton and 60% of polyester;

[0034] Concrete preparation process is as follows:

[0035] 1) First, the natural cotton strands are made into natural cotton strands through the processes of cleaning, opening, drawing, roving, spun yarn, winding, and twisting;

[0036] 2) Then, the polyester yarn is made into polyester yarn lines through loosening, carding, roving, spun yarn, and winding processes;

[0037] 3) Finally, the prepared natural cotton strands are used as the warp and the polyester yarn as the weft, and the middle layer fabric is made through a weaving process.

[0038] b) Prepare the upper elastic fabric layer yarn line, the material composition and percentage content of the upper elastic fabric layer are 12% spandex, 23% nano-bamboo charcoal fiber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com