Mo-C-codoped method for preparing one-dimensional titanate nanobelt photocatalyst material

A photocatalyst and nanobelt technology, applied in the field of nanomaterials and nanometers, can solve problems such as nanobelt materials that have not yet been seen, and achieve the effects of remarkable photocatalysis, reduction of synthesis cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

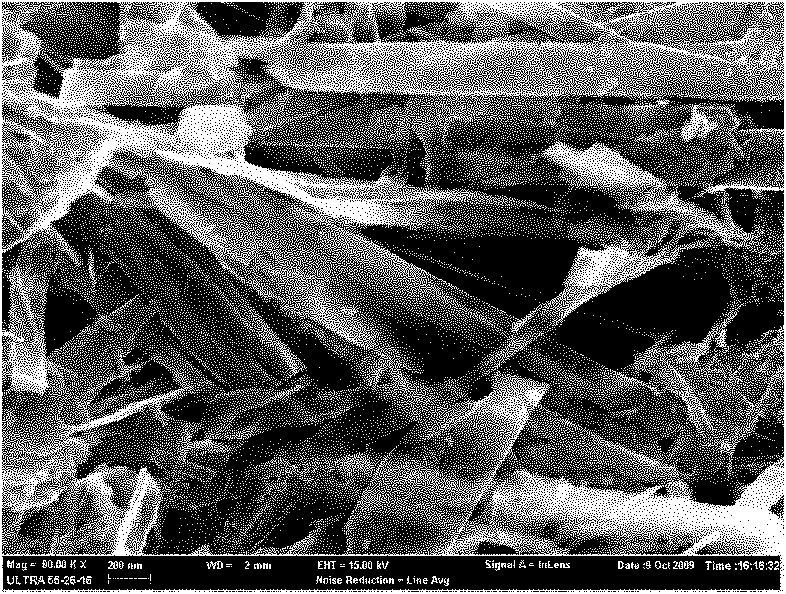

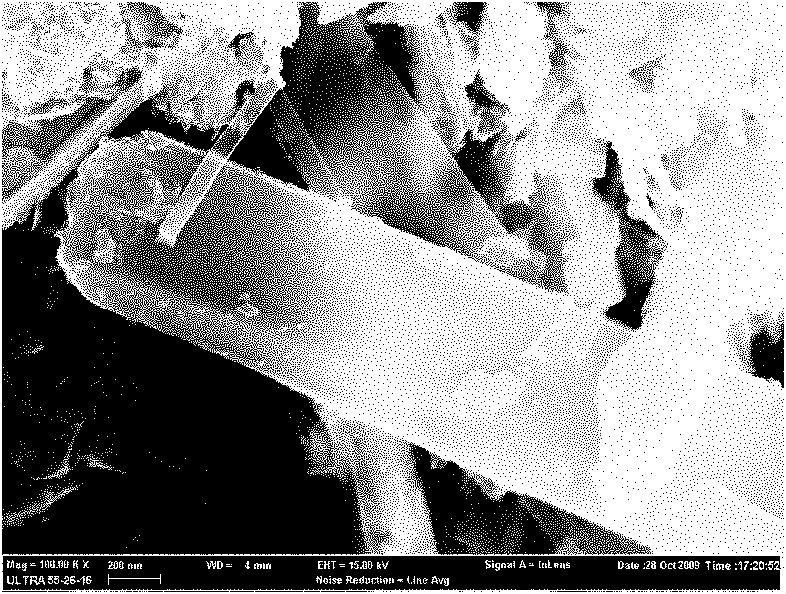

[0024] The Mo+C co-doped preparation method of one-dimensional titanate nanobelt photocatalyst material, it comprises the steps:

[0025] (1) Dissolve 45 mL of butyl titanate in 180 mL of absolute ethanol, then add 4.5 mL of glacial acetic acid, and adjust the pH to 3.0 with concentrated nitric acid (commercially available), accompanied by vigorous stirring;

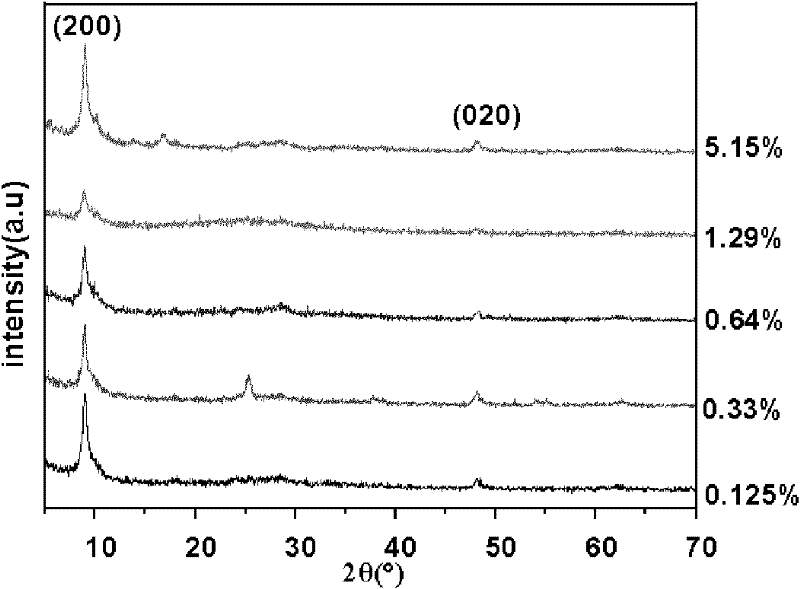

[0026] (2) According to the mass ratio of Mo element / Ti element (0.125%, 0.25%, 0.33%, 0.64%, 1%, 1.29%, 5.15%), add ammonium molybdate aqueous solution (divided into 7 groups), stir for 1h, Then ultrasonically dispersed for 1.5h, dried at 80°C, and calcined at 500°C for 3h to obtain Mo-doped TiO 2 powder;

[0027] (3) TiO doped with Mo 2 Dissolve 3.33g of powder and 0.20g of glucose into a sodium hydroxide solution with a volume of 100mL and a concentration of 10M and stir vigorously for 40h to obtain a suspension solution;

[0028] (4) Then adopt the hydrothermal method to react hydrothermally at a temperature of 18...

Embodiment 2

[0037] The Mo+C co-doped preparation method of one-dimensional titanate nanobelt photocatalyst material, it comprises the steps:

[0038] (1) Dissolve 45 mL of butyl titanate in 180 mL of absolute ethanol, then add 4.5 mL of glacial acetic acid, adjust the pH to 3.0 with concentrated nitric acid (commercially available), and stir;

[0039] (2) Add ammonium molybdate aqueous solution according to the mass ratio of Mo element / Ti element 0.1, stir for 1 h, then ultrasonically disperse for 1.5 h, dry at 80°C, and calcinate the obtained product at 500°C for 3 h to obtain Mo-doped TiO 2 powder;

[0040] (3) TiO doped with Mo 2 Dissolve 3.33g of powder and 0.1g of glucose into a sodium hydroxide solution with a volume of 100mL and a concentration of 2M and stir vigorously for 30h to obtain a suspension solution;

[0041] (4) Then adopt the hydrothermal method to react hydrothermally at a temperature of 160° C. for 2 days, and adjust the pH value to 7.0 by adding HCl solution (0.1M...

Embodiment 3

[0045] The Mo+C co-doped preparation method of one-dimensional titanate nanobelt photocatalyst material, it comprises the steps:

[0046] (1) Dissolve 45 mL of butyl titanate in 180 mL of absolute ethanol, then add 4.5 mL of glacial acetic acid, adjust the pH to 3.0 with concentrated nitric acid (commercially available), and stir;

[0047] (2) Add ammonium molybdate aqueous solution according to the mass ratio of Mo element / Ti element 6%, stir for 1h, then ultrasonically disperse for 1.5h, dry at 80°C, and calcinate the obtained product at 500°C for 3h to obtain Mo-doped TiO 2 powder;

[0048] (3) TiO doped with Mo 2 Dissolve 3.33g of powder and 1.5g of glucose into a sodium hydroxide solution with a volume of 100mL and a concentration of 20M and stir vigorously for 50h to obtain a suspension solution;

[0049] (4) Then adopt hydrothermal method to react hydrothermally at a temperature of 220° C. for 4 days, and adjust the pH value to 7.0 by adding HCl solution (0.1M) dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com