Vent hole pricking device

A vent hole and cylinder technology, applied in the field of casting molding, can solve the problems of ineffective quality assurance, high manufacturing cost, and low production efficiency, and achieve the effects of improving efficiency, ensuring quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

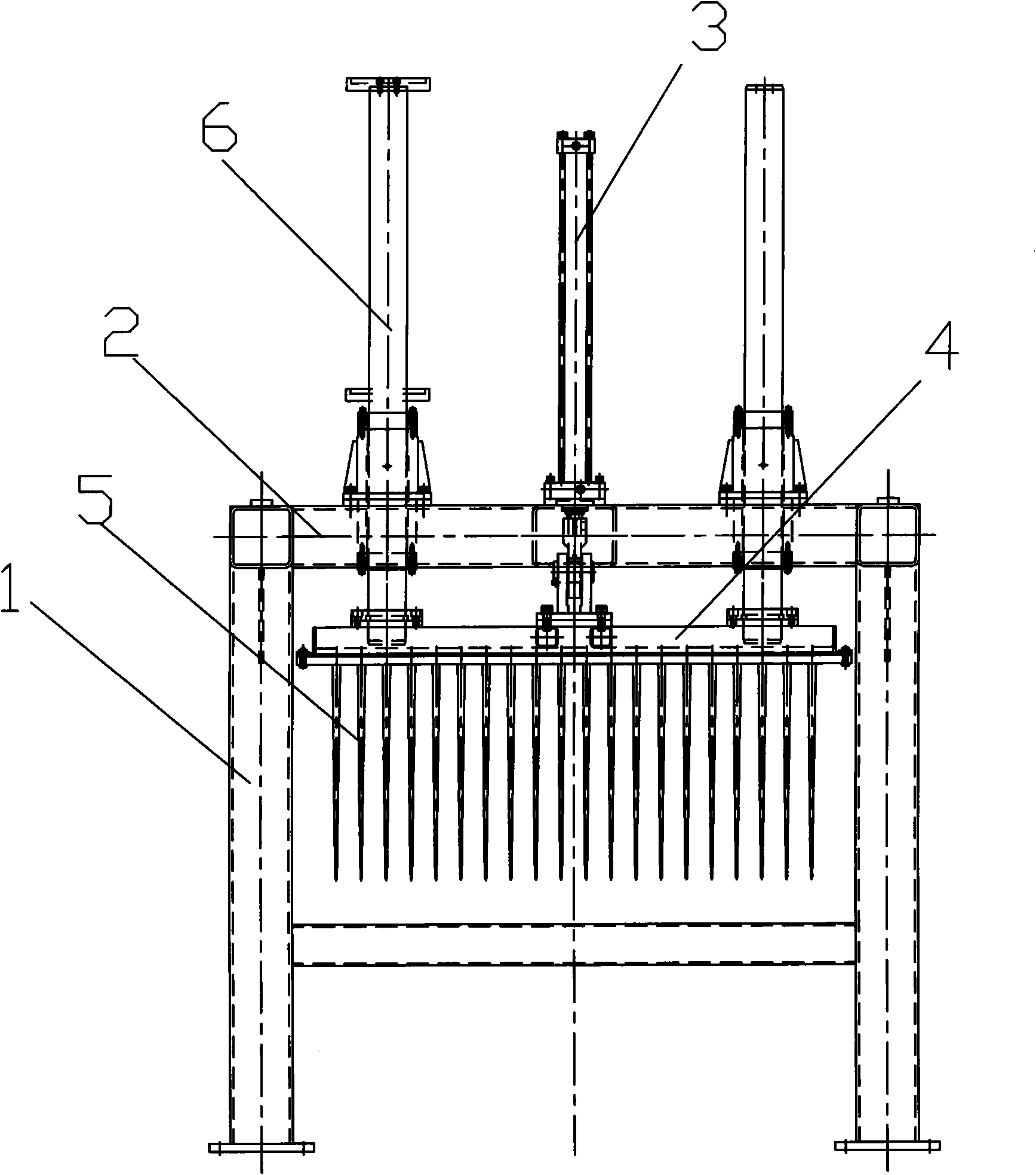

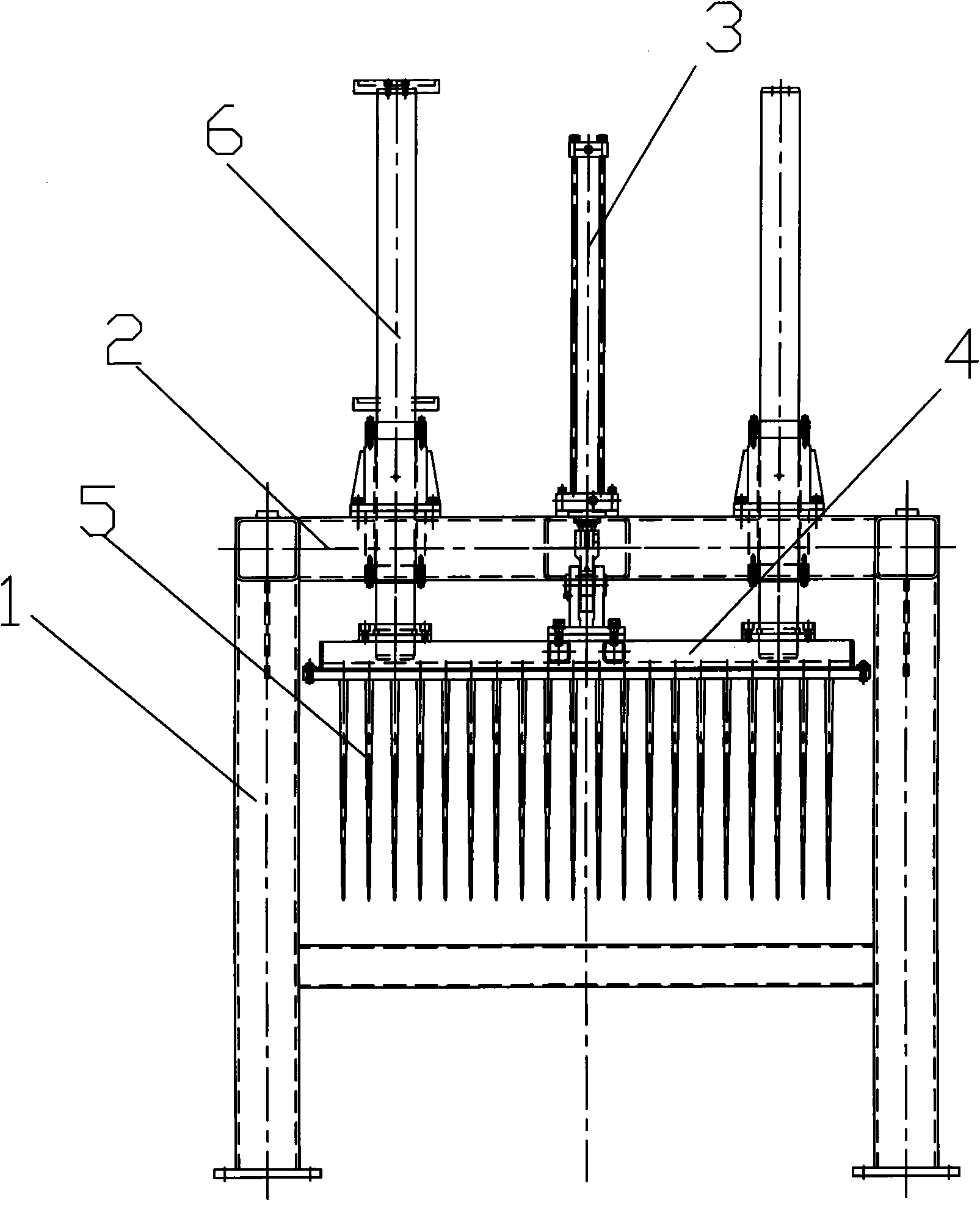

[0012] Such as figure 1 As shown, the air vent device includes a mounting bracket 1, a beam 2 is arranged on the top of the mounting bracket 1, a cylinder 3 is arranged on the beam 2, the piston rod of the cylinder 3 is connected with a needle mounting plate 4, and the needle mounting plate 4 is There are several needles 5. A guide column 6 is respectively arranged on both sides of the cylinder 3 , and the guide column 6 can slide through the beam 2 and connect with the needle mounting plate 4 . When the piston rod of the cylinder 3 drives the needle mounting plate to move up and down, the guide post 6 can play a guiding role.

[0013] When the air vent device is in use, the sand core is first placed under the needle mounting plate, and then the cylinder is driven to move the needle mounting plate downward, so that the needle pierces severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com