Shield originating or receiving end tunnel portal maintenance process

A technology of end tunnel door and shield tunneling, which is applied in shaft lining, tunnel lining, underground chamber, etc. It can solve the problems that the inner layer of the tunnel door is not suitable for demolition, catastrophic accidents are prone to occur, and the timing of demolition is difficult to grasp, etc., to achieve Avoid catastrophic accidents, simple and easy to operate plugging process, outstanding economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

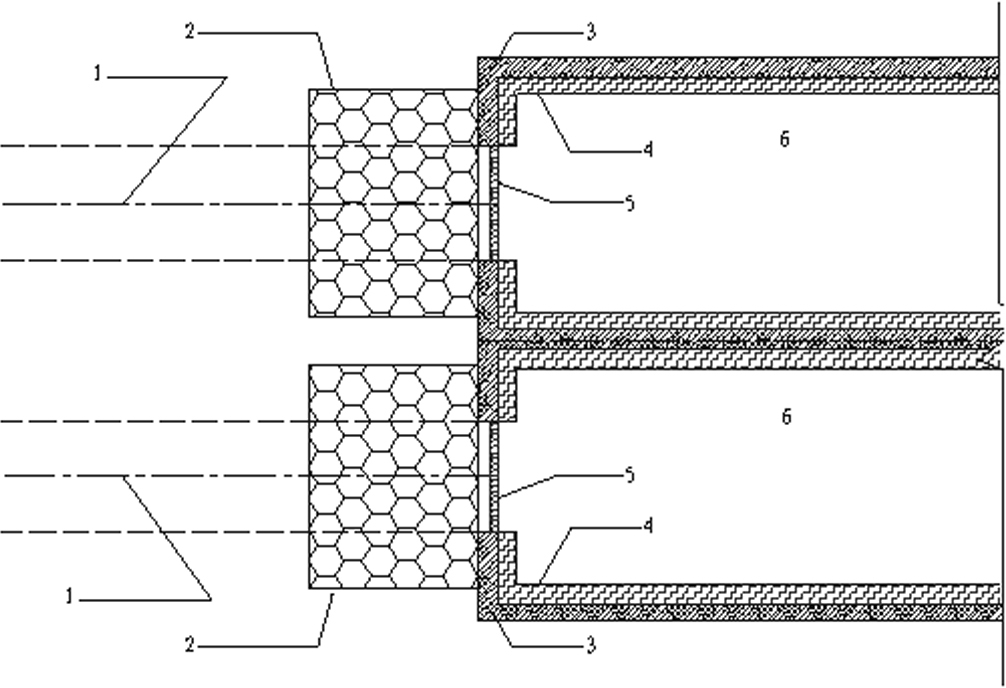

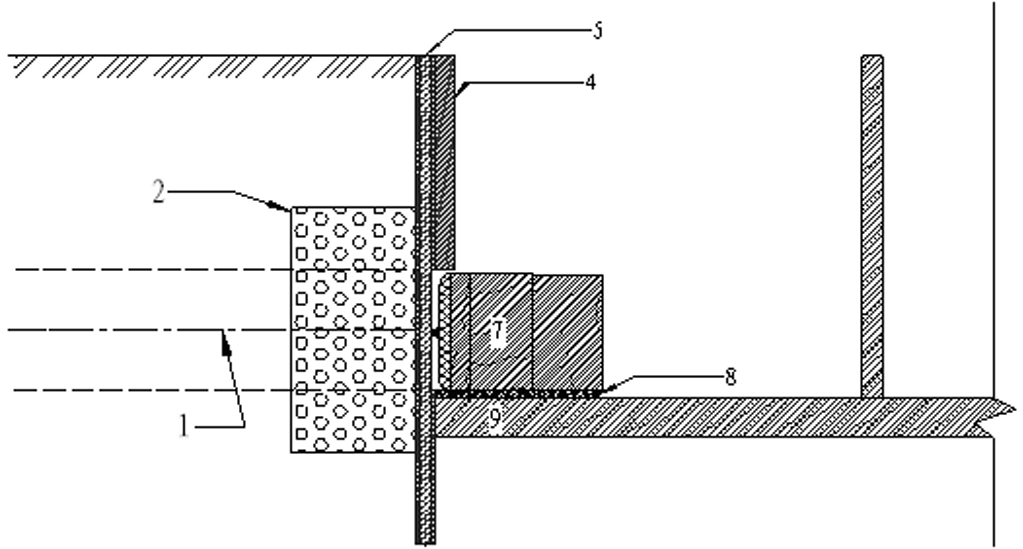

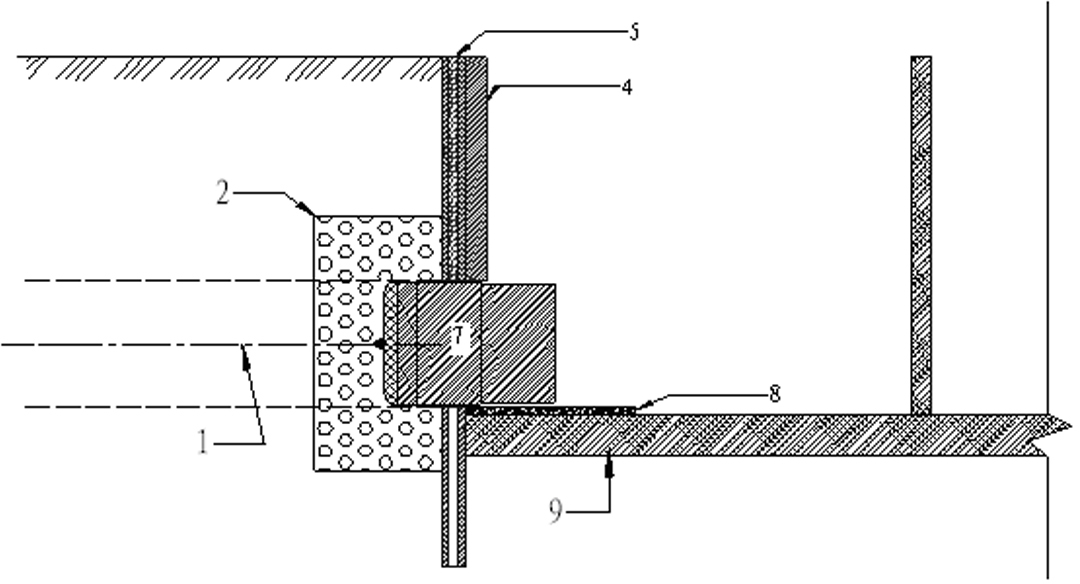

[0021] During the construction of the portal maintenance wall, a steel sheet pile is inserted at the portal position to replace the steel bars at this position, and the steel sheet piles can be known by those skilled in the art from the prior art. Such as figure 1 As shown, move the steel sheet pile up and down before the initial setting of the maintenance wall concrete to prevent the steel sheet pile from being pulled out due to excessive bonding force between the steel sheet pile and the wall concrete; The reinforcement design scope of the slurry reinforcement method; figure 2 As shown, when the shield machine starts, wait until the shield machine advances until the cutter head reaches the steel sheet pile of the portal; image 3 As shown, the steel sheet pile can be pulled out and the shield machine can be pushed forward. Such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com