System and method for recognizing rolling guide rail joint surface dynamic characteristic parameters

A technology of rolling guide and dynamic characteristics, applied in the field of test identification system, can solve problems such as poor stiffness, and achieve the effect of reducing complexity, simple and reliable experimental device, and reducing experimental error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

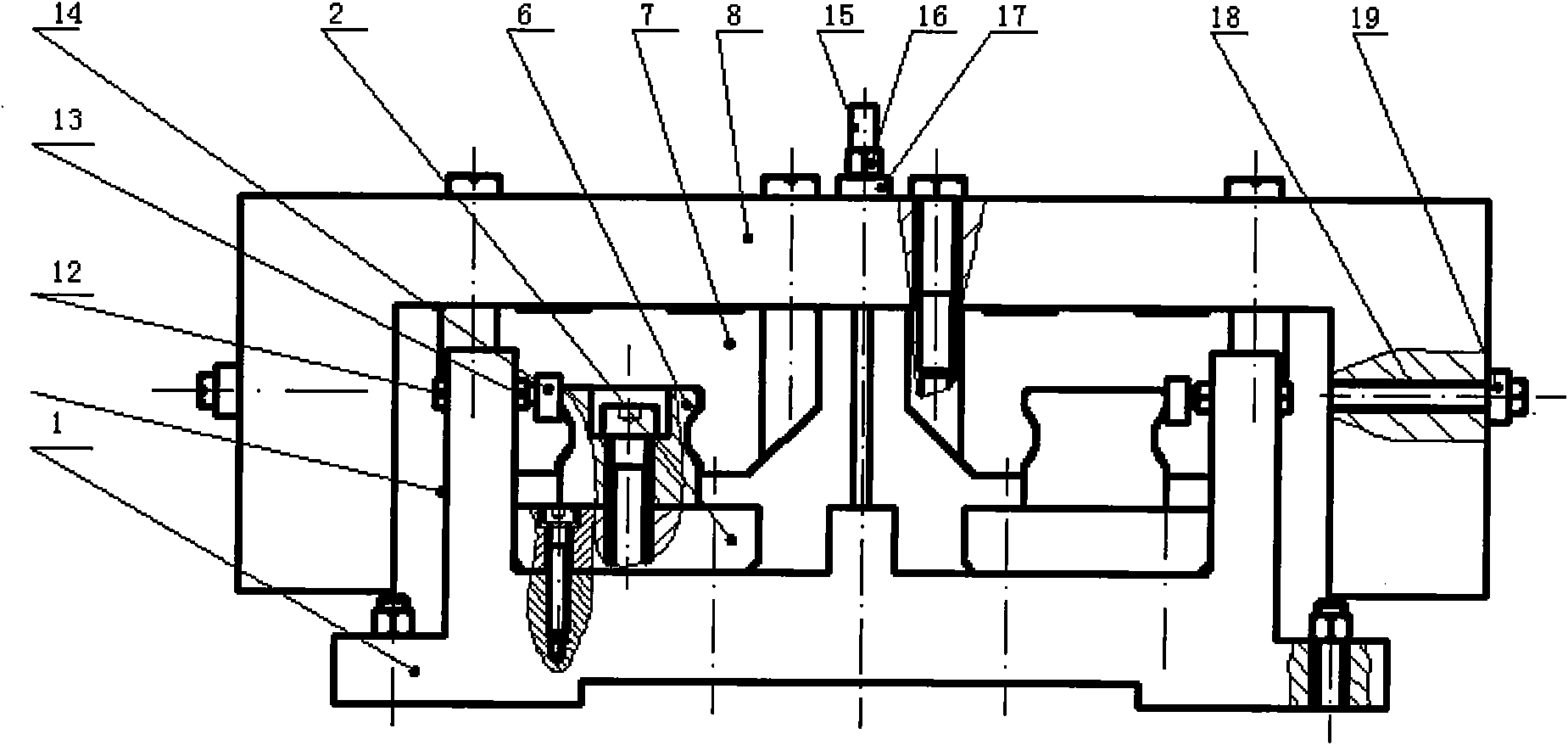

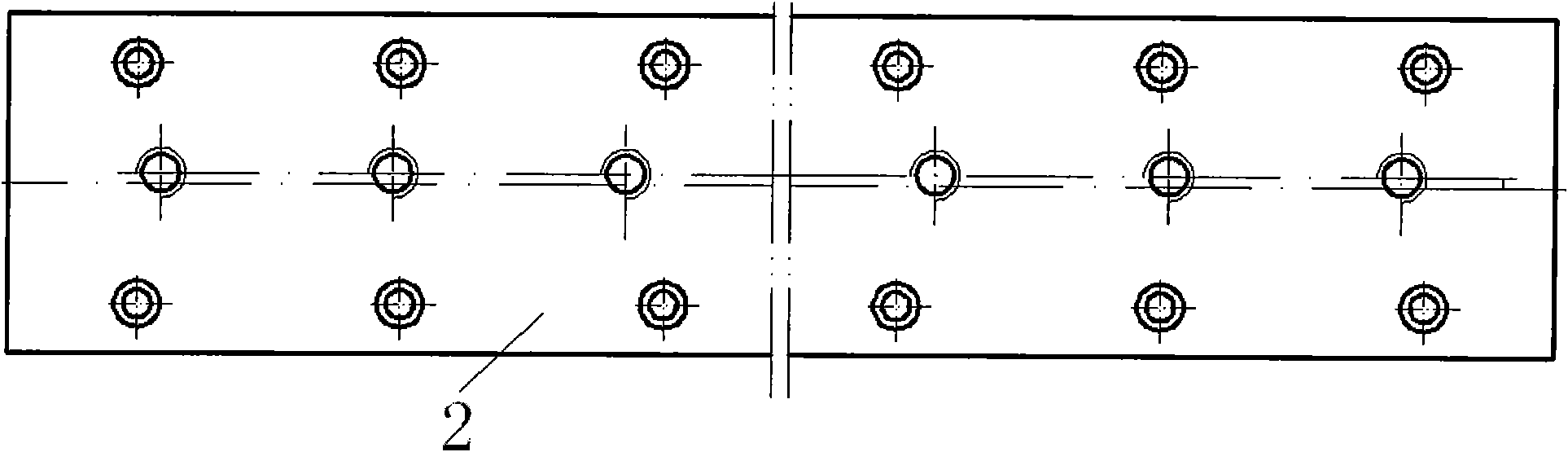

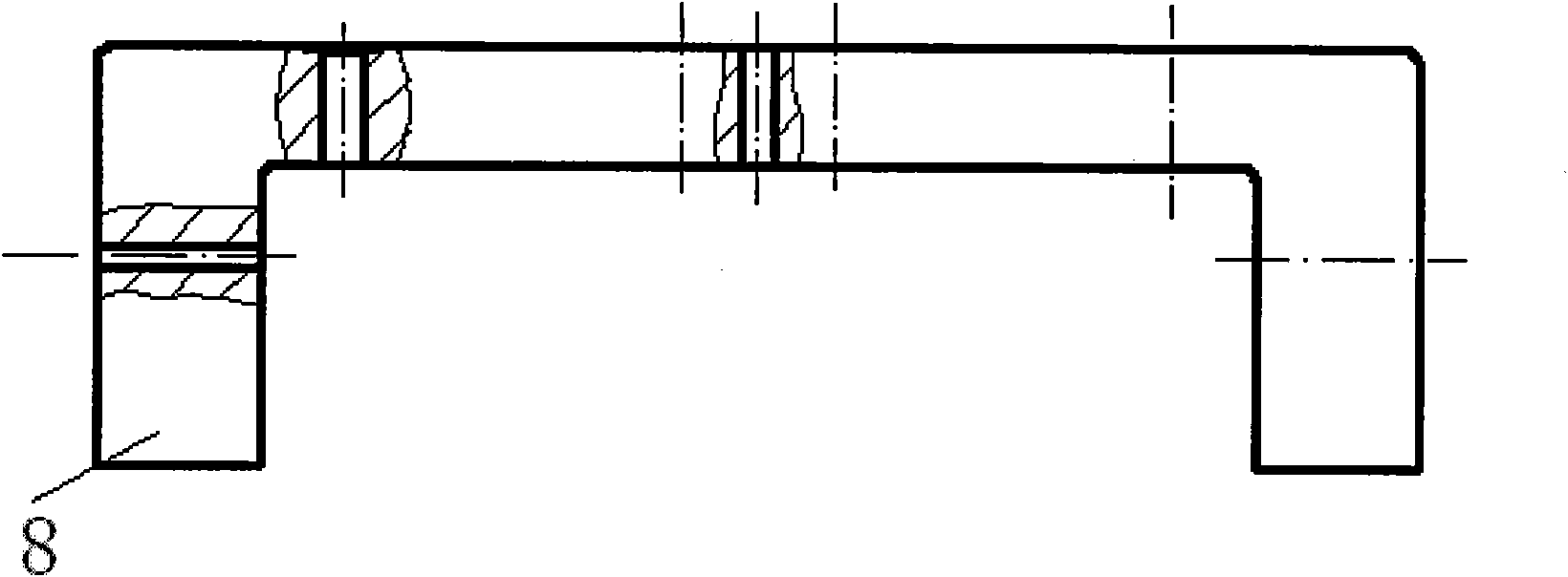

[0054] Experimental device of the present invention such as figure 1 As shown, the rolling guide rail group composed of guide rail 6 and slider 7 corresponds to Schneiberger rolling guide rail group MRB65, MRA55, MRA45 and MRA35 in the device of the present invention. The overall structure adopts a symmetrical structure, which is symmetrical about the center plane of the test bench 1, including the base, the rolling guide rail group, the connecting plate, the guide rail fixture device, the normal pressure device, the tangential pressure device, and the drive execution module. part, of which:

[0055] The base is composed of the replaceable adjustment blocks corresponding to the MRB65, MRA55, MRA45 and MRA35 types of the Schneiderberg rolling guide group and the test bench 1. The replaceable adjustment block corresponds to the replace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com