A location method of pasting ACF membrane on screen substrate of flat-panel display

A flat-panel display and display technology, applied in instruments, identification devices, nonlinear optics, etc., can solve the problems of waste of ACF film, failure to guarantee the accuracy of ACF film application, short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0178] A kind of aligning method of pasting ACF film on the display substrate of flat panel display, its content is as follows:

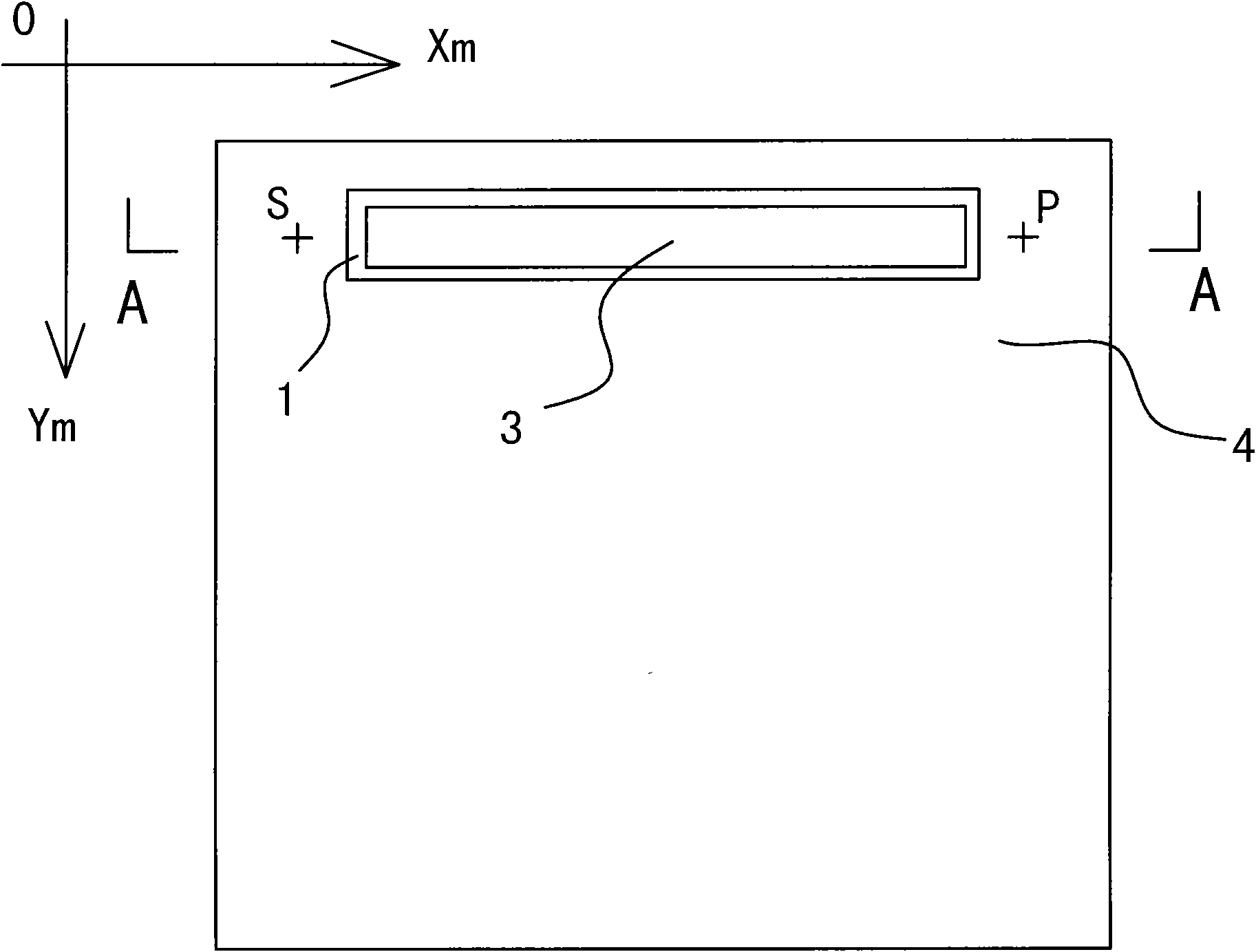

[0179] (1) Alignment reference and alignment method

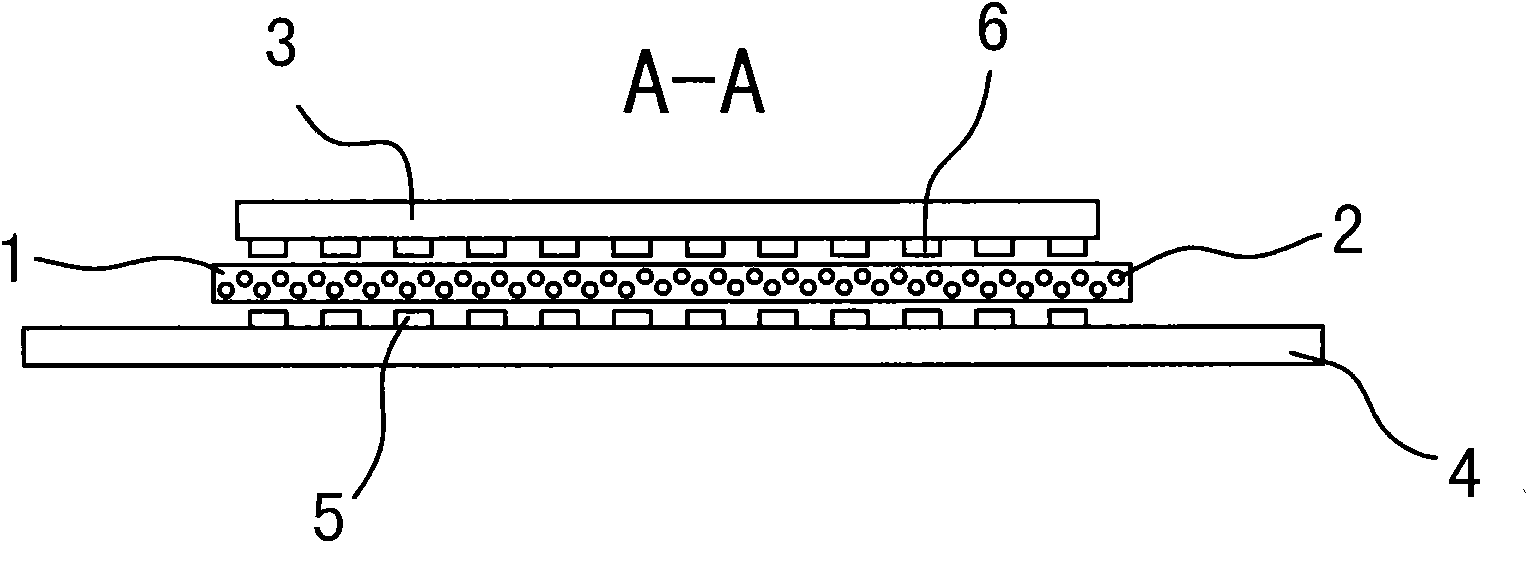

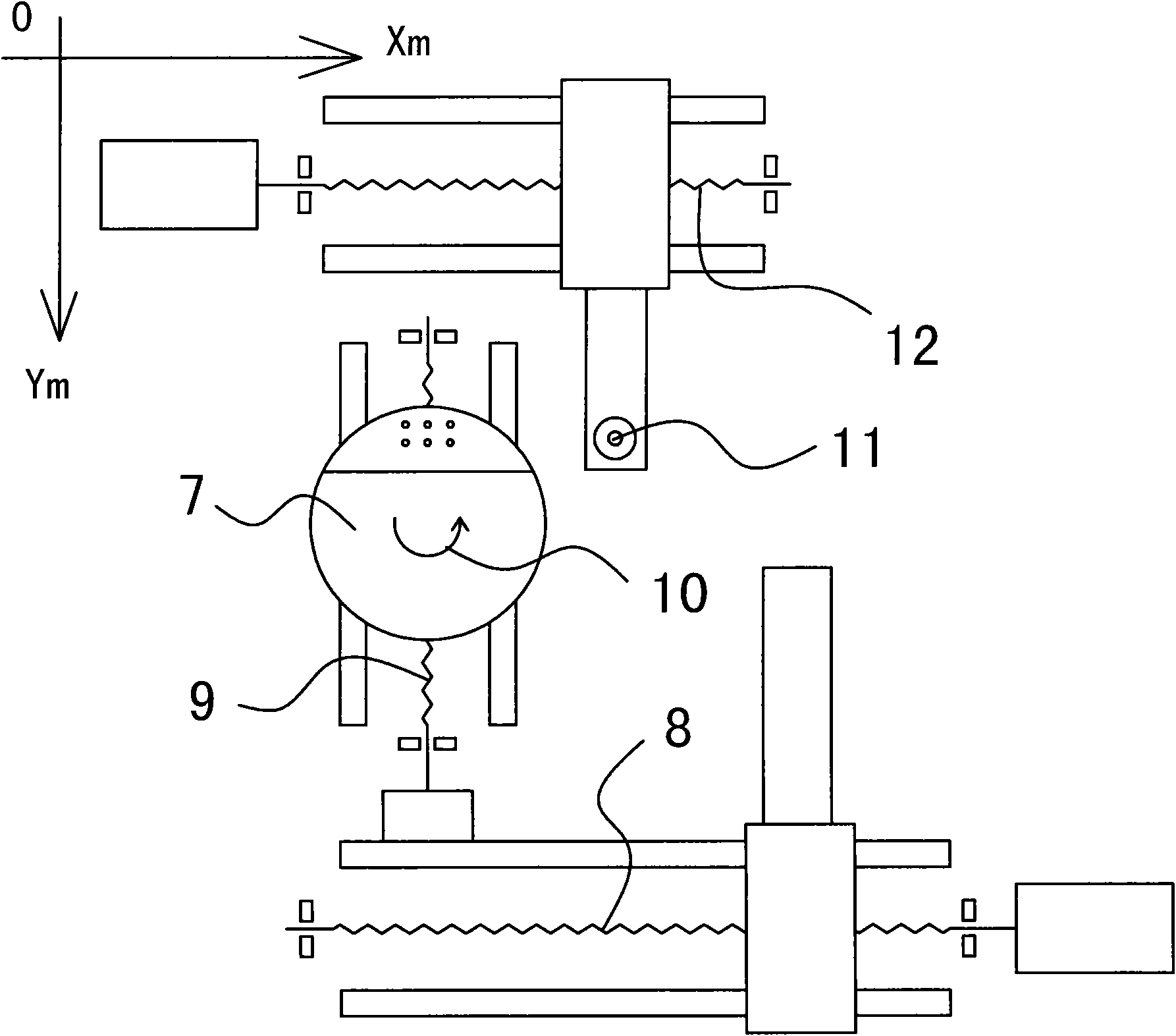

[0180] In ACF membrane 1 (see figure 1 and figure 2 ) The mechanical coordinate system M where the mounting plane is located (see figure 1 and figure 2 In the mechanical coordinate system drawn in), with the position and direction of the ACF film 1 in the mechanical coordinate system M as the target, by adjusting the display substrate (such as figure 1 The alignment of the ACF film 1 and the driving terminal area (the area formed by the driving terminals 5 ) on the display substrate is realized by the position and direction of the LCD liquid crystal panel 4 ).

[0181] (2) Adjustment method

[0182] In advance, in the same process of making the driving terminals on the display substrate, two marking points for image recognition (such as figure 1 S and P in ), convert the alignment bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com