Combustion gas bleeding probe, and method for running the probe

一种燃烧气体、运转方法的技术,应用在废热处理、照明和加热设备、炉子组件等方向,能够解决性能降低、得不到、寿命缩短等问题,达到性能提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

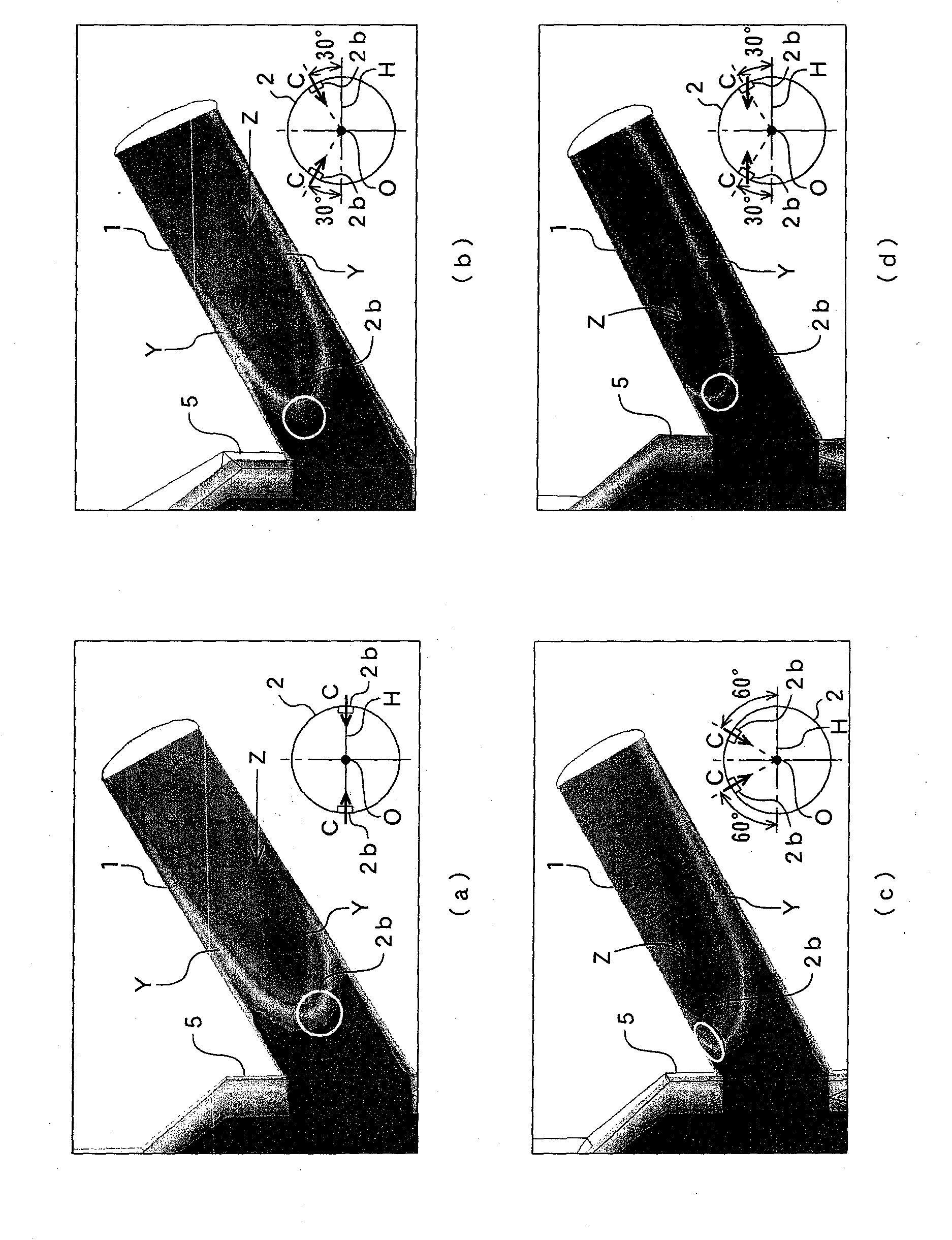

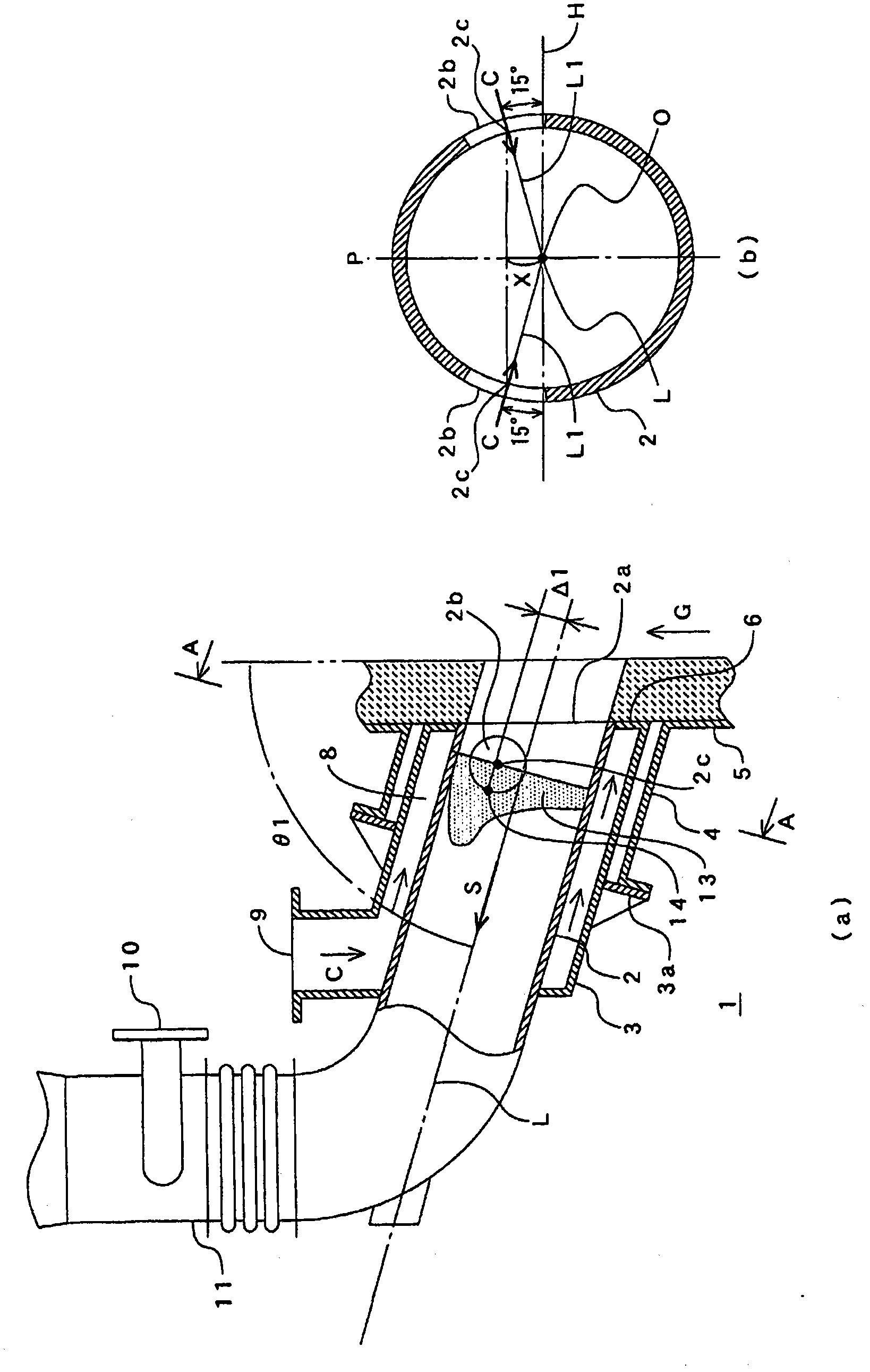

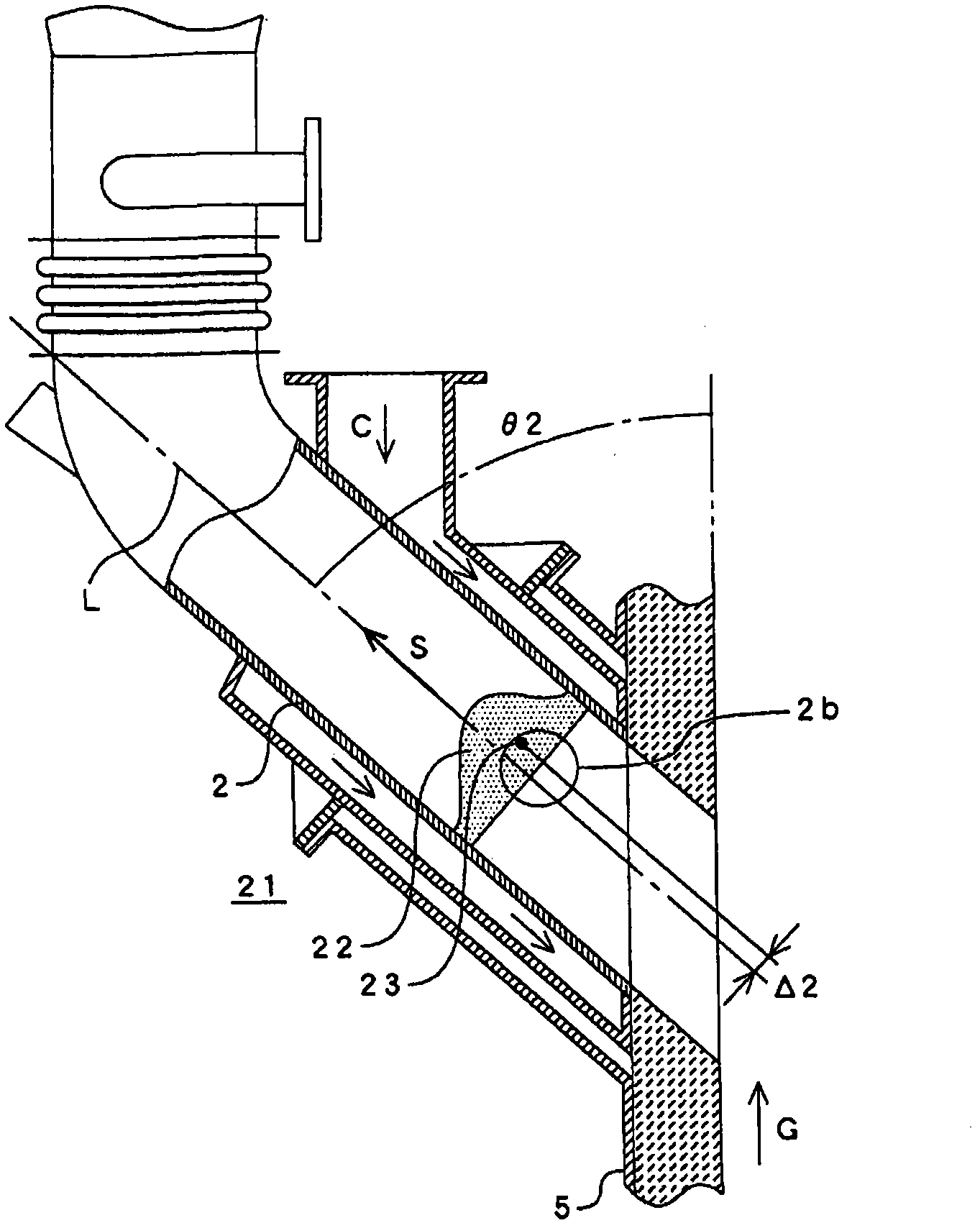

[0044] Next, embodiments of the present invention will be described with reference to the drawings.

[0045] figure 1 (a) shows an embodiment of the combustion gas extraction pipe (hereinafter, simply referred to as "pipe") of the present invention, and the pipe 1 includes: a cylindrical inner cylinder 2; a cylindrical outer cylinder surrounding the inner cylinder 2 3; the ring-shaped end plate 6 as a plate member fixed on the front end of the outer cylinder 3; the cooling air passage 8 formed between the inner cylinder 2 and the outer cylinder 3; The cooling air is supplied to the cooling air passage 8 through the primary cooling air supply port 9 and the like, and the pipe 1 is installed on the standing portion 5 of the cement kiln through the mounting base 4 . A secondary cooling air supply port 10 for cooling to a uniform temperature is provided on the pipe 11 on the downstream side of the pipe 1 .

[0046] The inner cylinder 2 cools the high-temperature combustion gas G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com