Novel roll mill

A roller mill, a new type of technology, applied to roller mills. It can solve the problems of low service life, low technical content and small use range, and achieve the effect of long service life, wide application range and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

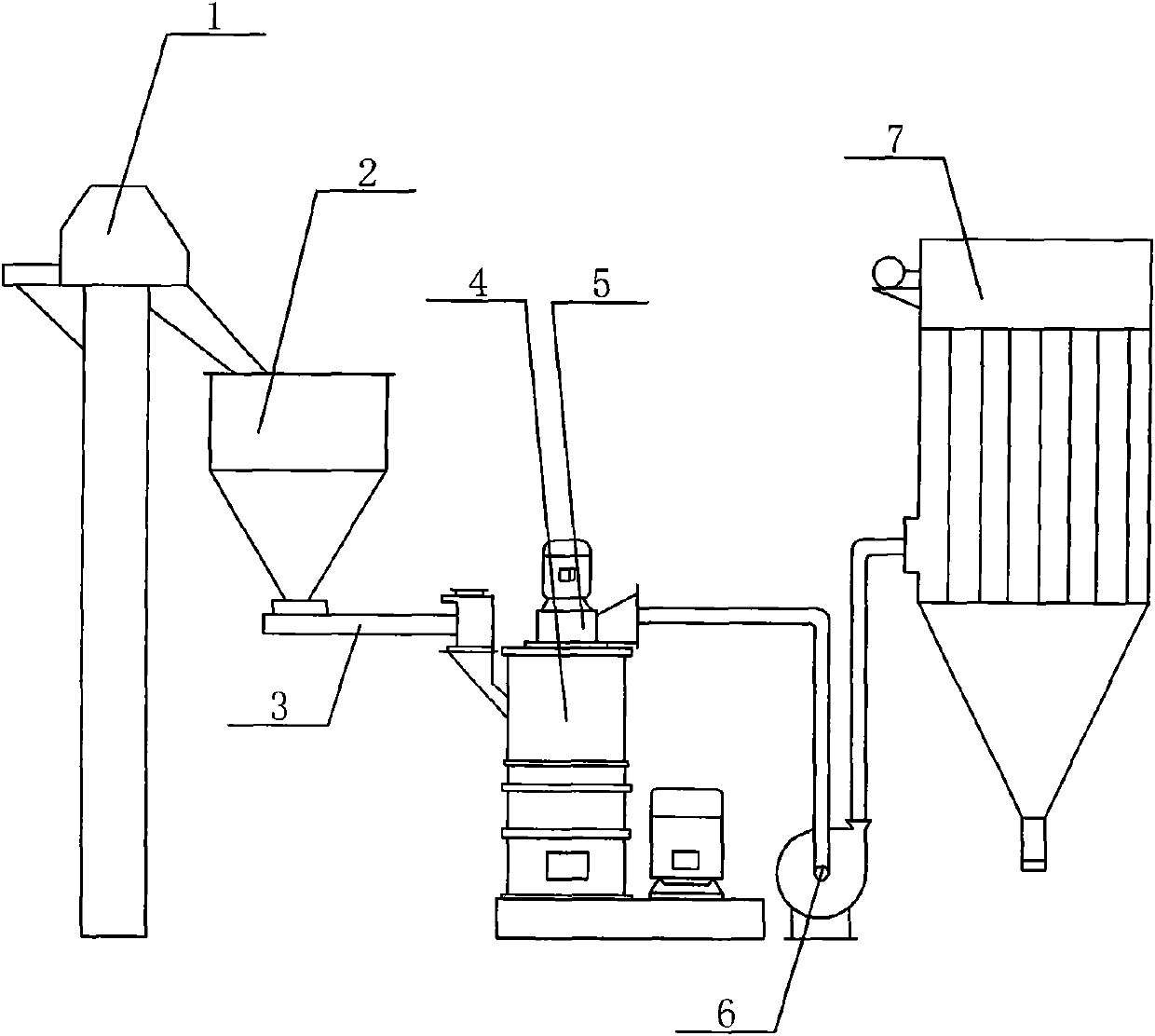

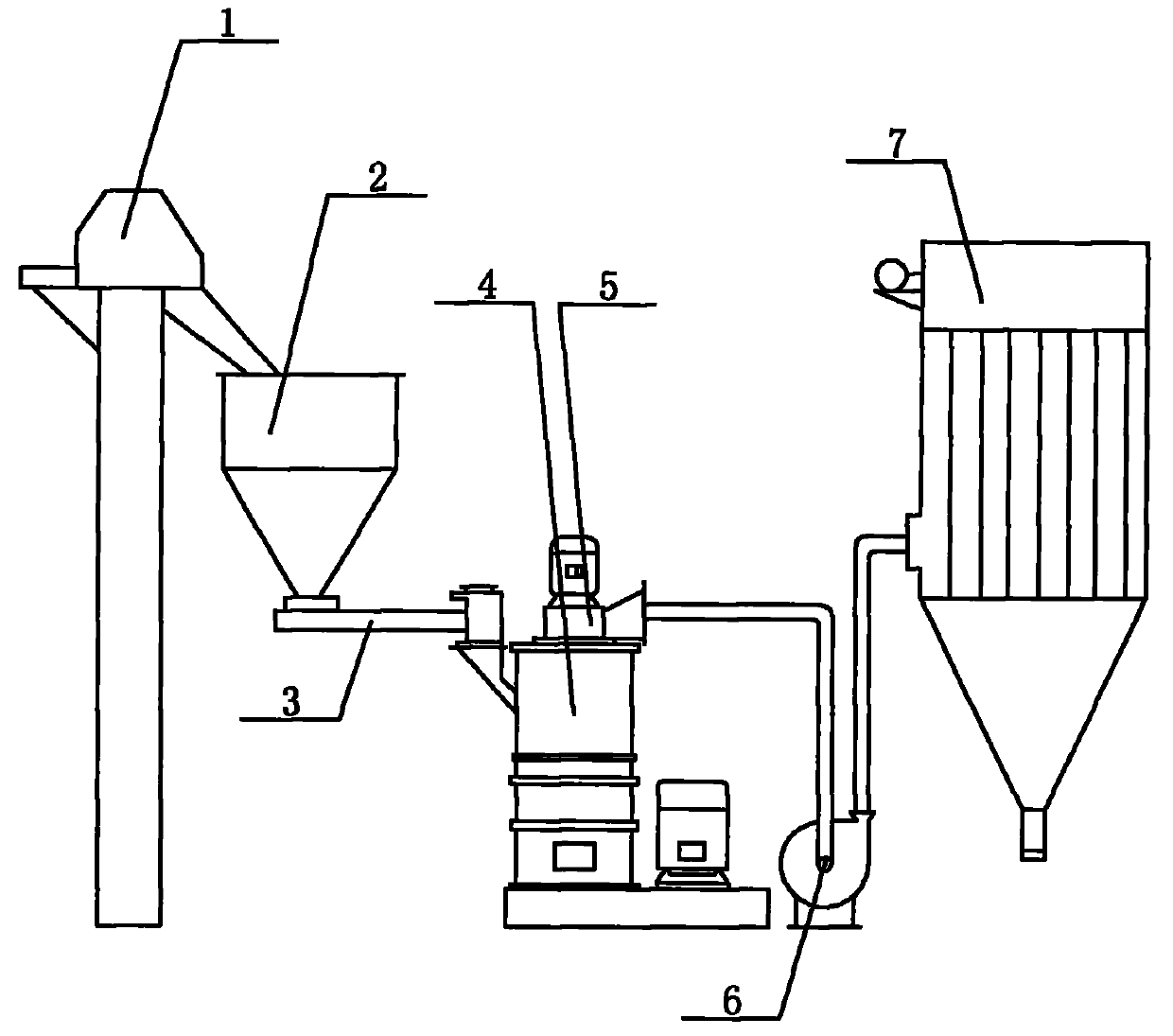

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: it is composed of hoist 1, silo 2, frequency conversion feeding device 3, crushing system 4, classification system 5, induced draft fan 6 and pulse dust collector 7, the upper end of hoist 1 It is connected to the upper end of the silo 2, the lower end of the silo 2 is connected to one end of the frequency conversion feeding device 3, the other end of the frequency conversion feeding device 3 is connected to the crushing system 4, and the classification system 5 is set on the upper end of the crushing system 4. The classification system The other end of 5 is connected with induced draft fan 6, and induced draft fan 6 is connected with pulse dust collector 7.

[0009] Elevator 1 transports materials into silo 2, and materials are fed into the crushing chamber of crushing system 4 through frequency conversion feeding device 3, and are crushed, sheared and ground by rollers to achieve sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com