Injector for textile processing machine

A technology for processing machinery and ejectors, applied in the directions of jetting device, jetting device, textile and papermaking, etc., can solve the problems of impossible to manufacture fleece fabric materials, different densities of messy non-woven fibers, etc., to avoid differences and reduce wall thickness. The effect of part thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

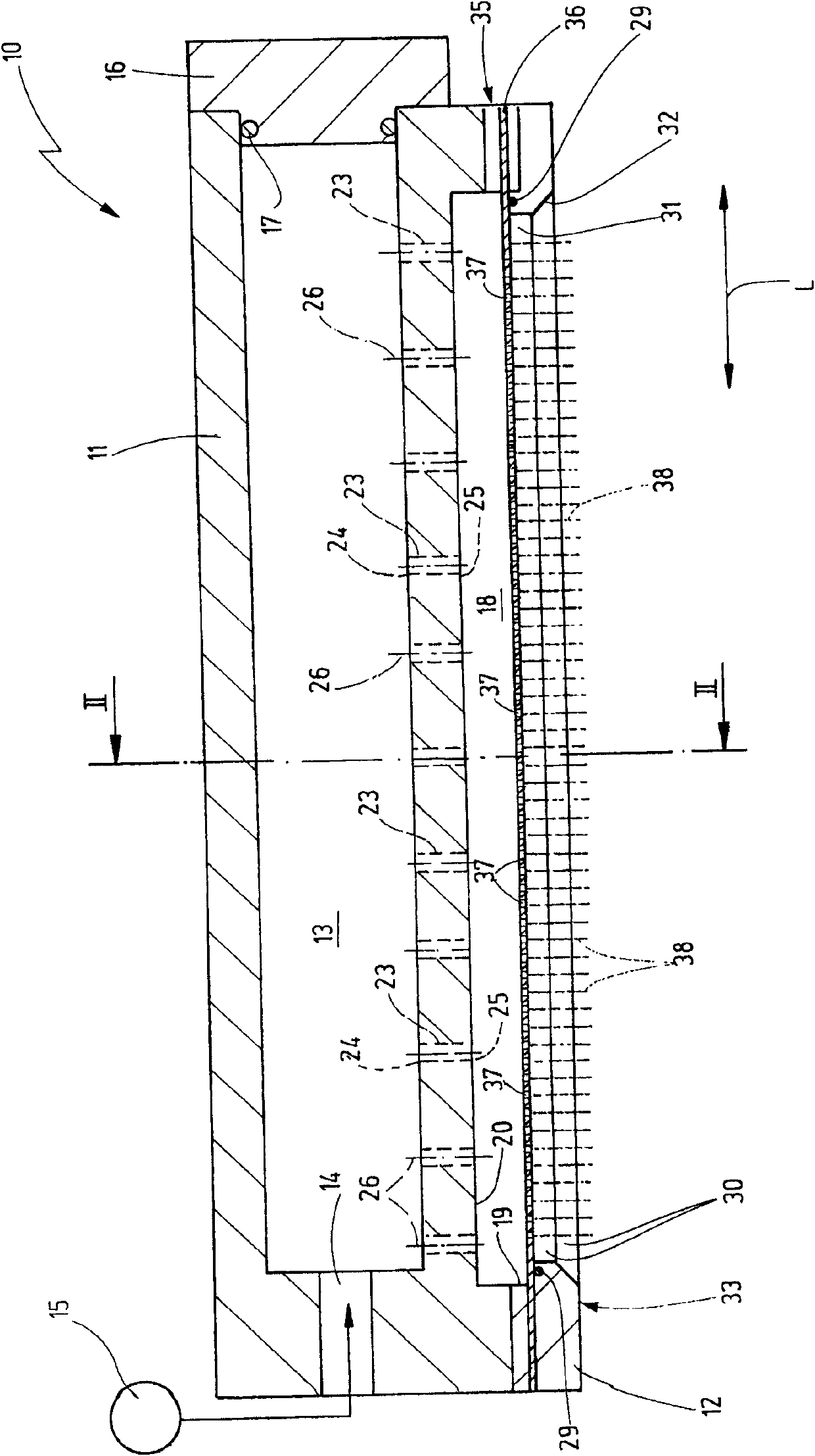

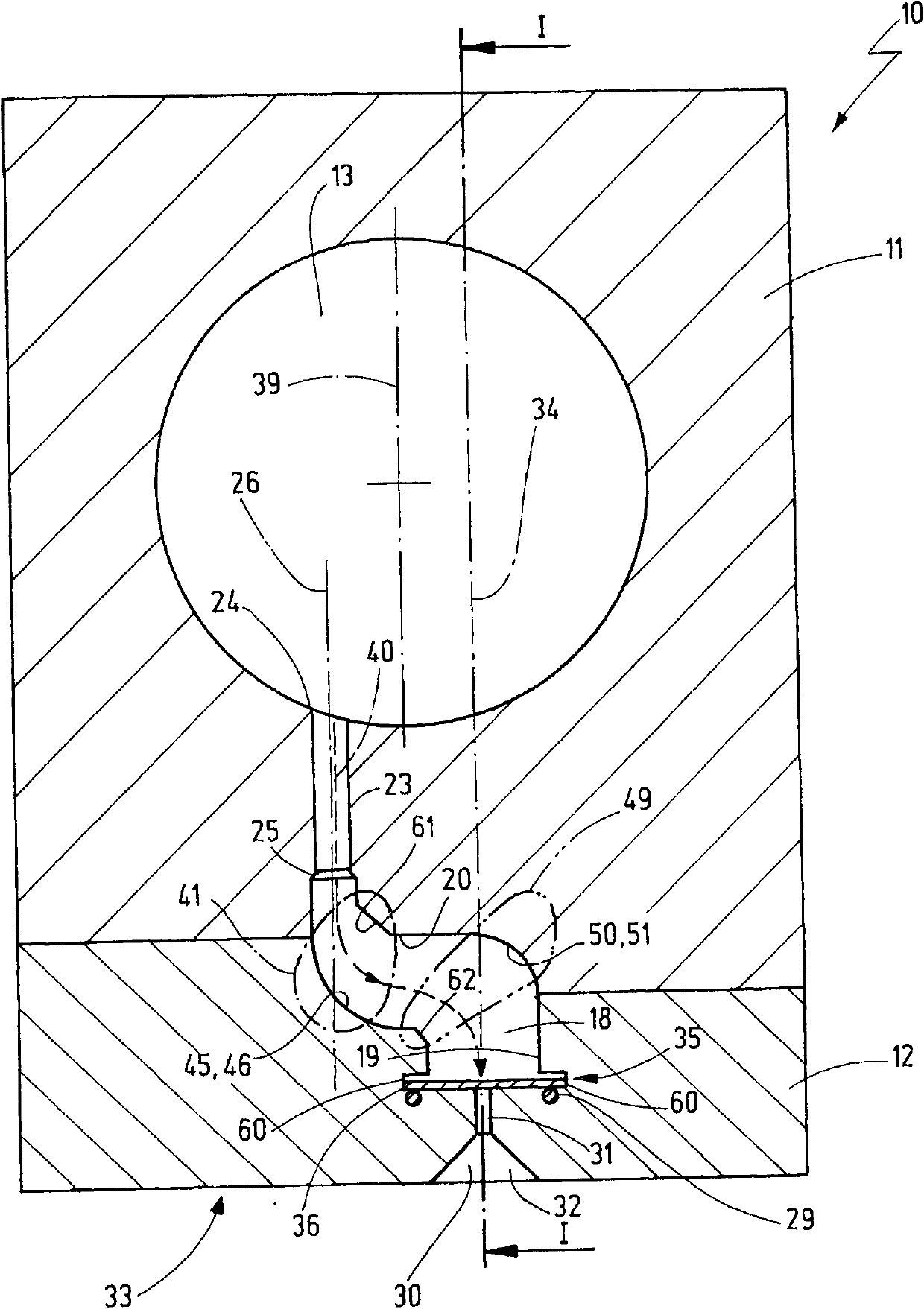

[0065] figure 1 A first exemplary embodiment of an injector 10 of a textile processing machine for producing pile fabric material is shown. The injector 10 includes an injector body 11 and an injector base 12 connected to each other. Inside the injector body 11 is an inflow chamber 13 which communicates with a pressure source 15 via an inflow opening 14 . In this exemplary embodiment, the inflow chamber 13 has a cylindrical shape. The inflow opening 14 is an aperture provided coaxially with respect to the longitudinal axis of the inflow chamber 13 . On the longitudinal end side opposite the inflow opening 14 , the inflow chamber 13 is closed in a fluid-tight manner by a screw-in cover 16 of the injector body 11 . To this end, an annular seal 17 may be provided between the cover 16 and the cover seat.

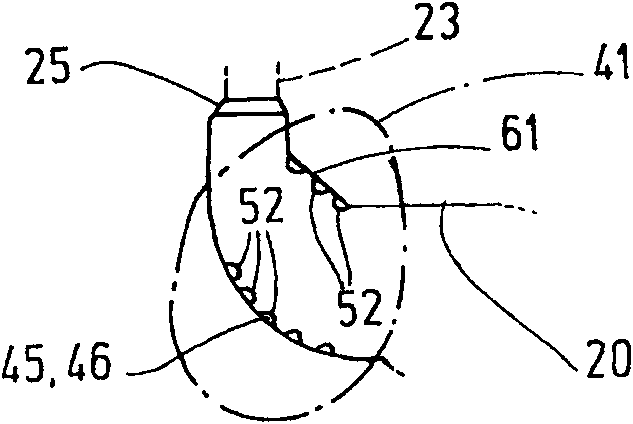

[0066] Furthermore, the injector 10 comprises a pressure distribution chamber 18 which extends in the longitudinal direction L in the region between the injector body 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com