Horizontal image online meter

An image and horizontal technology, which is applied in the field of horizontal image online instrument, can solve the problem that the image measuring instrument has a small loading space, cannot measure large-volume workpieces or the end face of long-shaped workpieces, and the measurement accuracy and degree of automation cannot fully meet the requirements of automation. Production and other issues, to achieve the effect of improving measurement accuracy and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing and preferred embodiment:

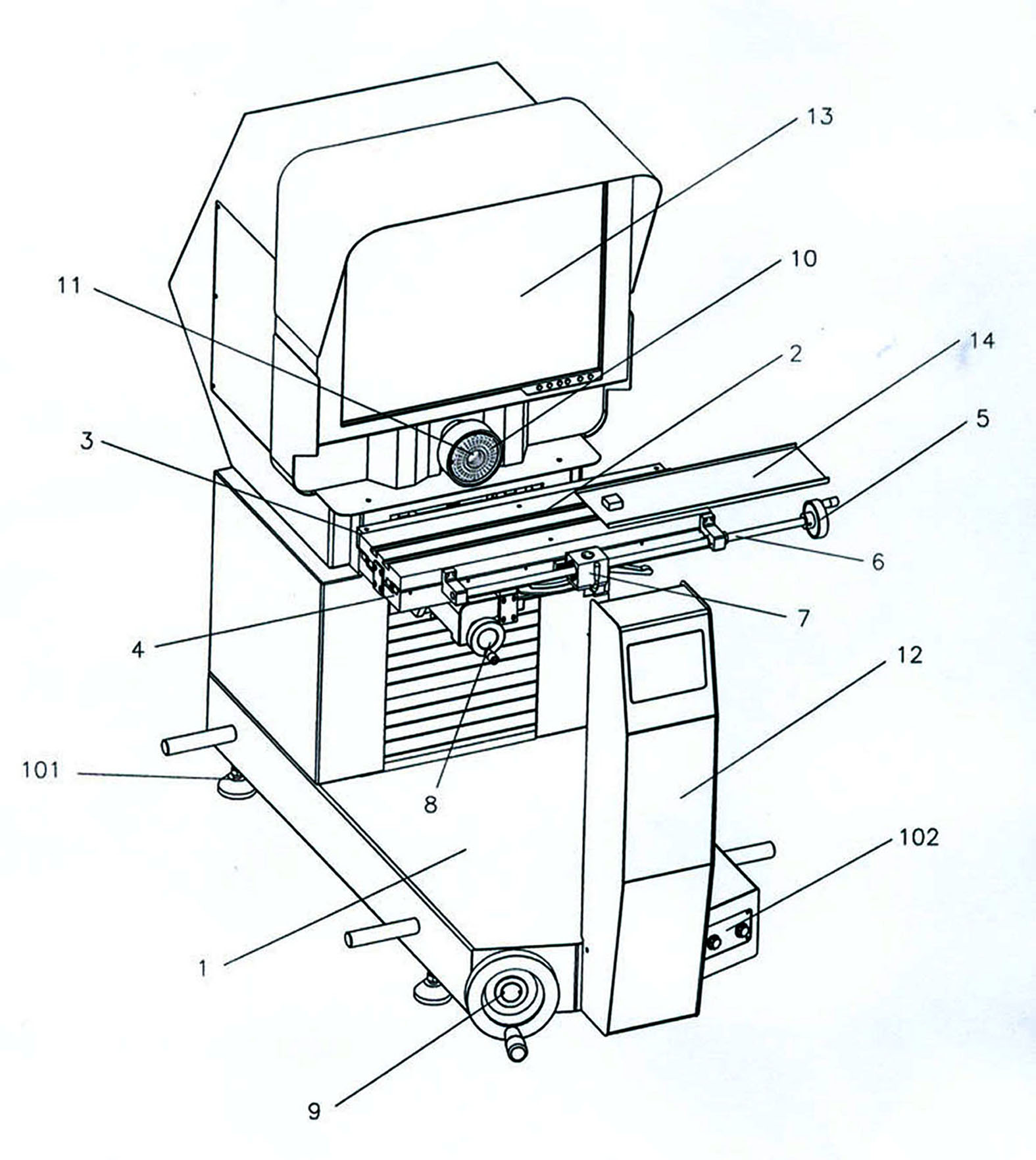

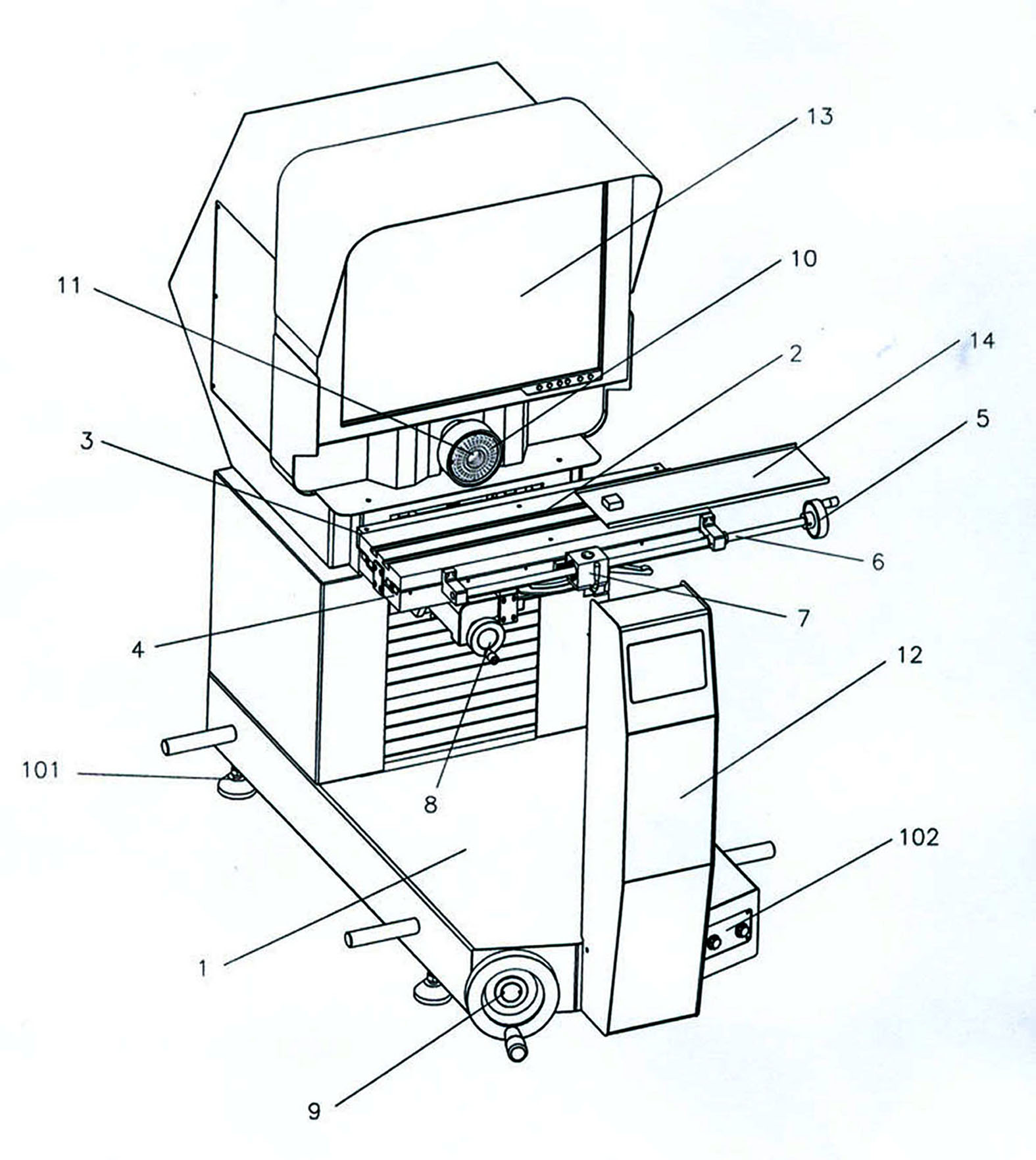

[0016] Such as figure 1 A horizontal image on-line instrument shown is composed of a frame, a workbench, an image component, a computer system and an automatic feeding device, and is used for the measurement and verification of workpiece products. in:

[0017] The frame is used to carry and fix the instrument. The bottom of the frame is the base 1. There are four feet 101 under the base 1 to adjust the balance of the instrument. There is a switch panel 102 on the right side in front of the base 1;

[0018] The workbench is installed on the base 1 and is used to carry the workpiece to be detected. The top of the workbench is a rectangular loading platform 2, and the bottom of the loading platform 2 is connected with a two-way slide rail group 4. The two-way slide rail set 4 From top to bottom, there are upper slide rails, middle slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com