Method and device for achieving positioning and shearing control of flying shear by process software

A technology of software implementation and cutting edge position, which is applied in the direction of automatic control device, feeding device, digital control, etc., can solve the problems of complex control system, high quality requirements of engineering personnel and maintenance personnel, and high control cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

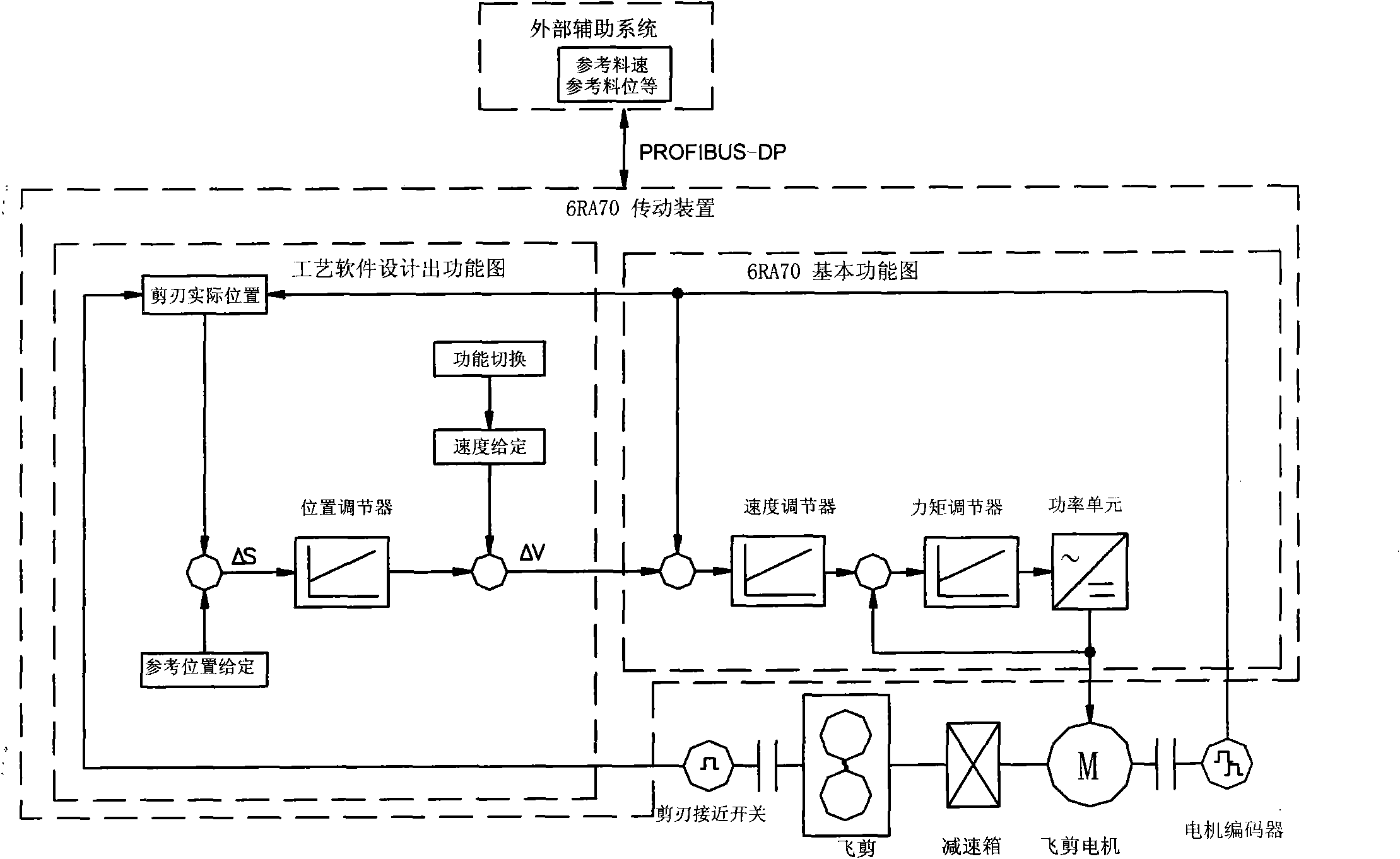

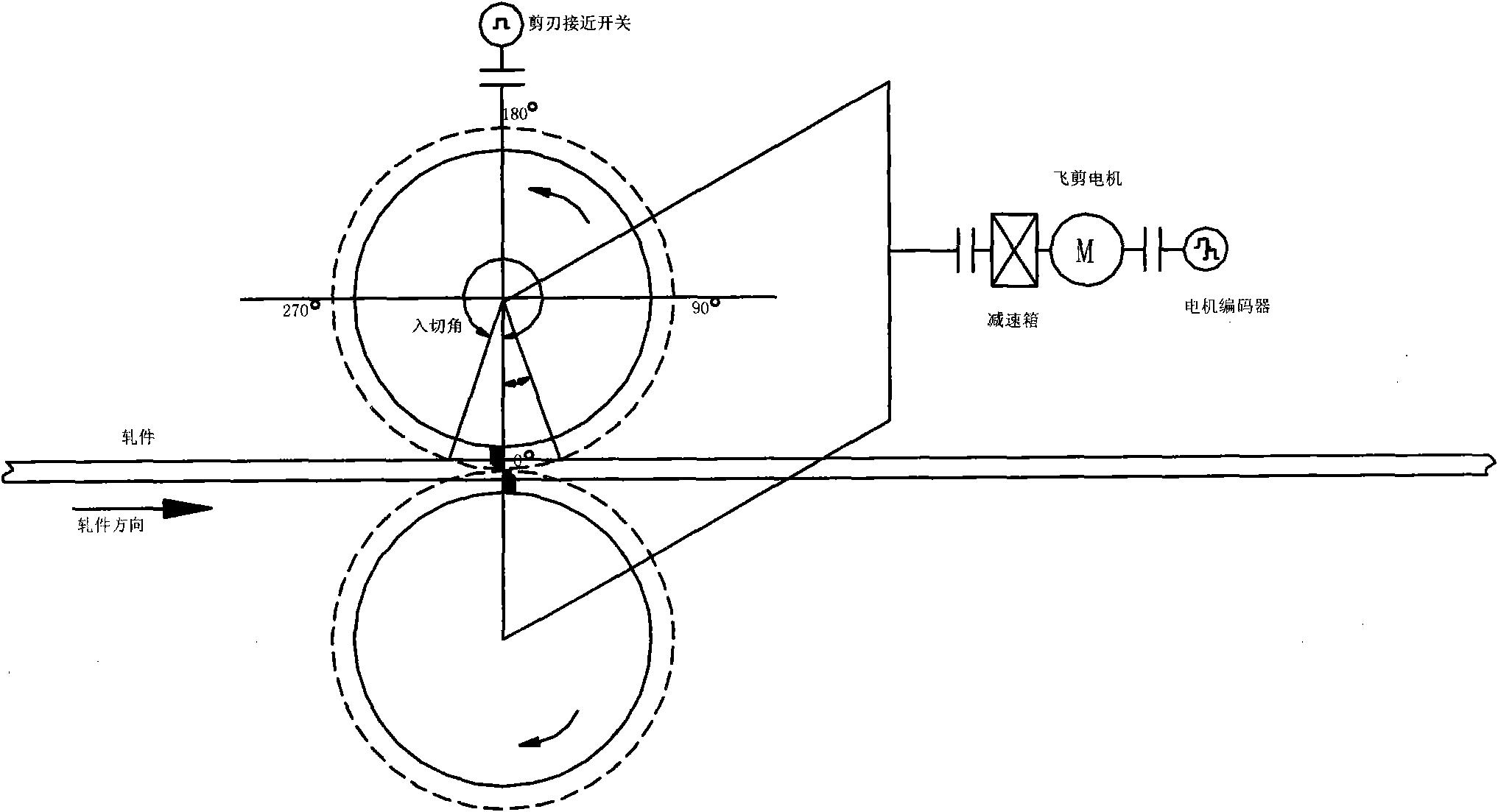

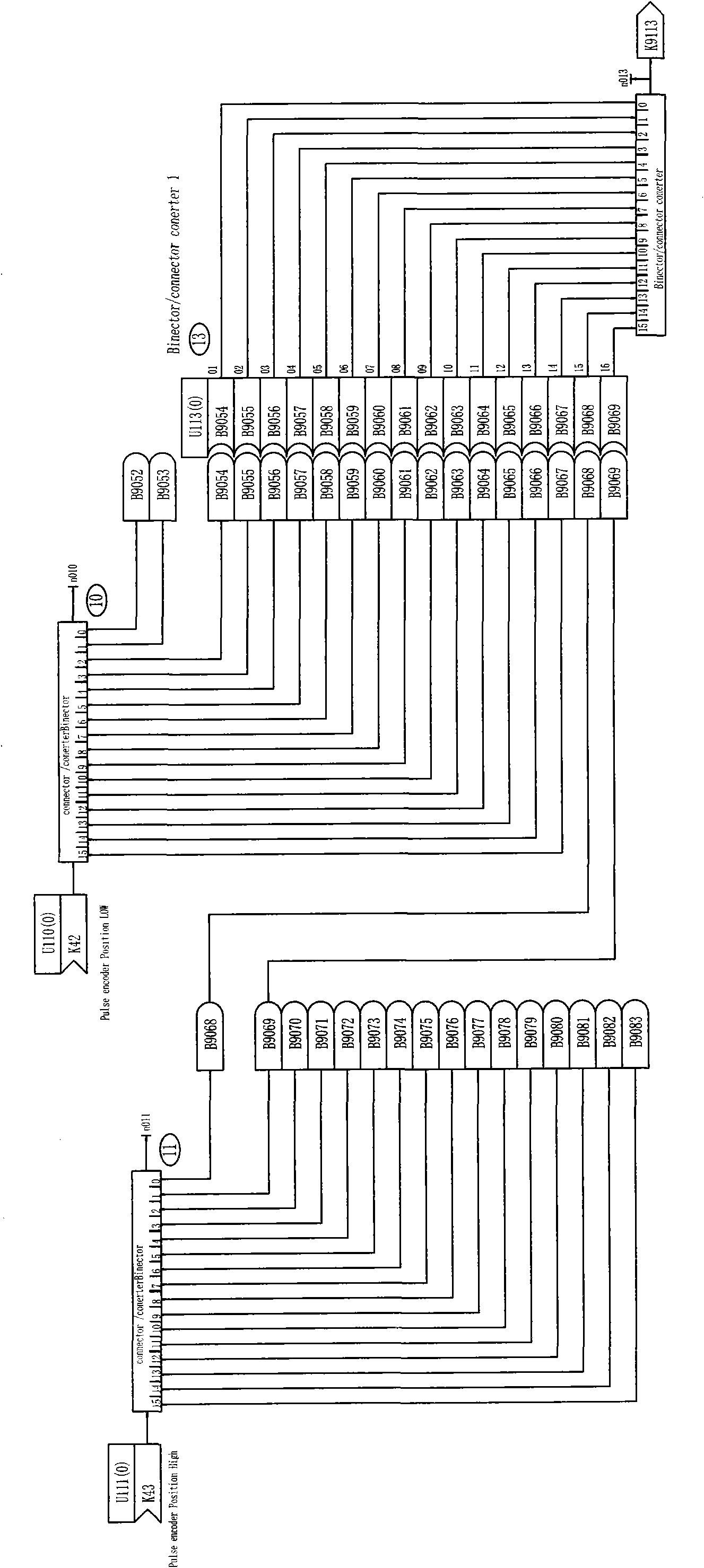

[0034] Such as Figure 1-7 As shown, the present invention only utilizes the built-in process software or programmable block in the transmission device of the flying shear motor to complete the precise positioning and cutting control of the flying shear. At present, the transmission device of flying shear basically has process software or programmable blocks. For example: SIEMENS DC device 6RA70 has process software S00, SIEMENS AC drive device 6SE70 has free free function blocks, ABB AC ACS800 and DC DCS800 devices have self-defined programming functions. Most of the driving motors for start-stop flying shears on the rolling line are DC motors, and most of the transmission devices are: SIEMENS SIMOREG DC-MASTER 6RA70. Taking the SIEMENS 6RA70 transmission device driving the flying shear DC motor as an example, the main technical solution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com