Template switching method for construction of integrated process of product reliability, maintainability and supportability (RMS) and performance

A template conversion and process template technology, applied in the direction of instruments, etc., can solve problems such as inability to handle well, shortage, poor effect, etc., and achieve the effect of shortening the development cycle, reducing the number of iterations, and eliminating coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

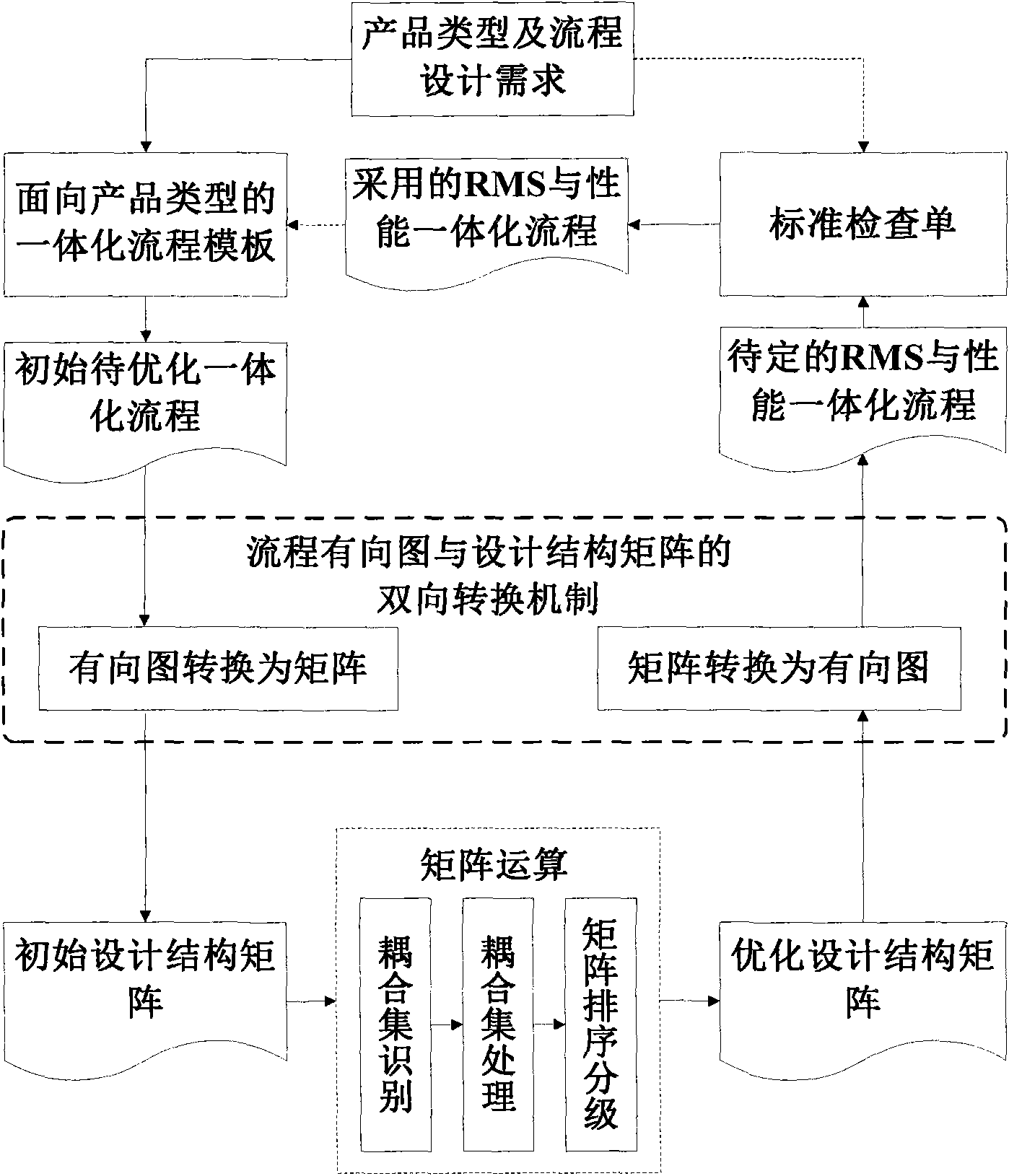

[0036] In order to make the features and advantages of the present invention more clearly understood, below in conjunction with accompanying drawing, describe in detail as follows: figure 1 The overall architecture of the present invention is described, wherein the direction of the solid arrow indicates the flow of the conversion method, and the direction of the dotted arrow indicates the selection or possible influence.

[0037] When an enterprise builds an RMS and performance integration process for a certain type of product, a template conversion method for building a product RMS and performance integration process according to the present invention, the specific implementation steps are:

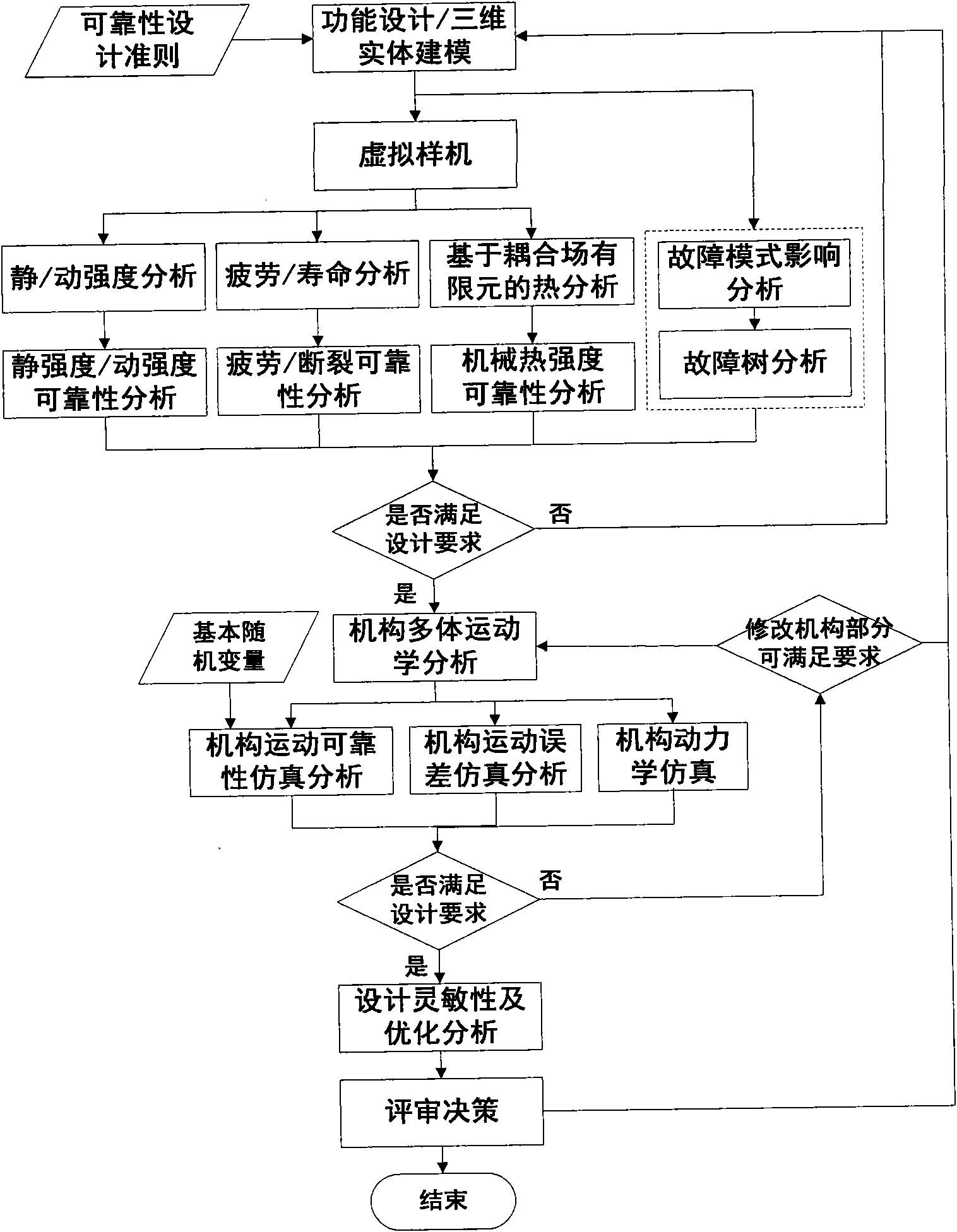

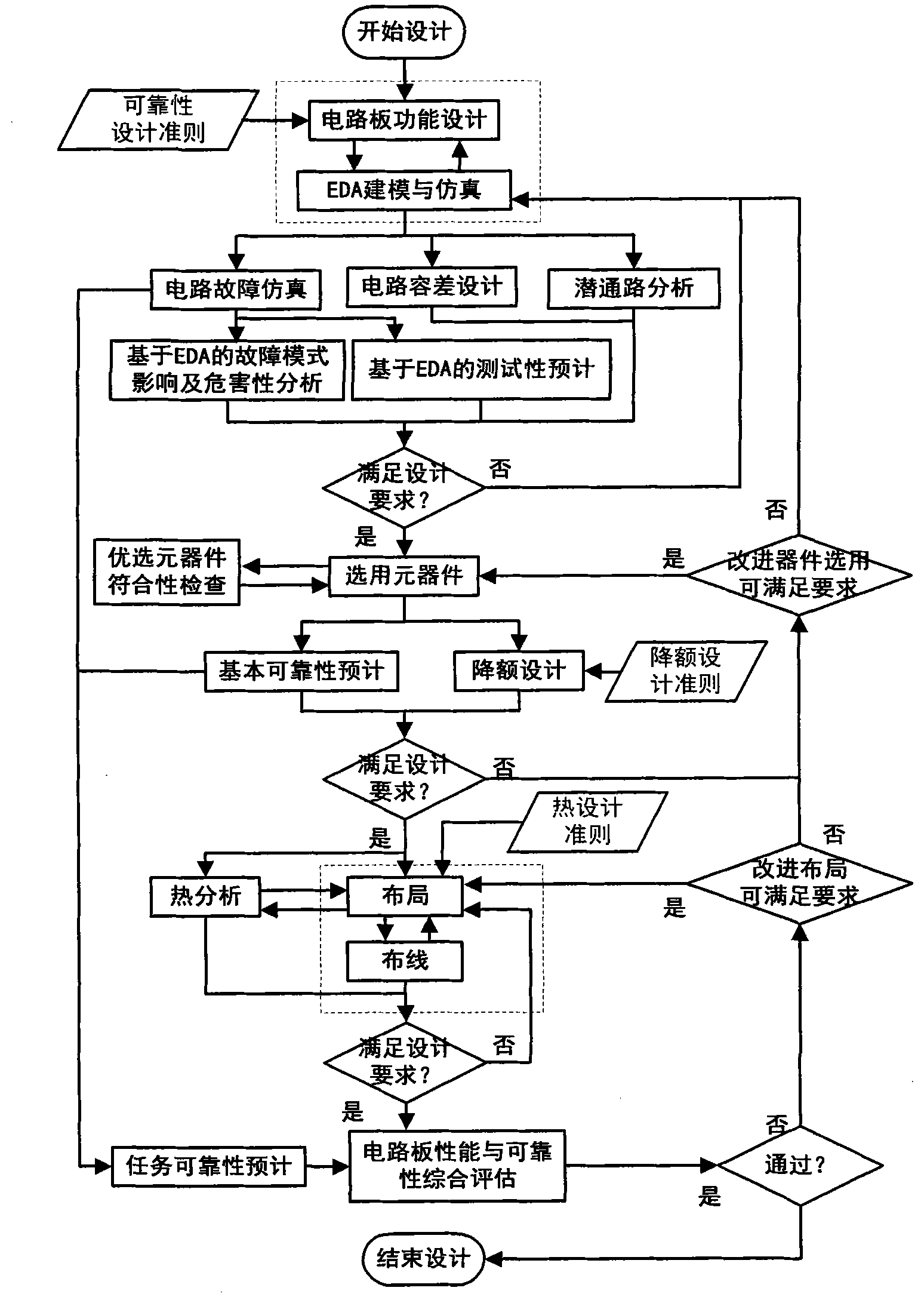

[0038] Step 1: According to the product type, such as mechanical, electronic, hydraulic, select the corresponding integrated process template (respectively such as figure 2 , image 3 , Figure 4 shown). Based on the template, the initial RMS and performance integration process to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com