Honeycomb-shaped crisp original taste coconut crisp chips

A honeycomb and coconut technology, which is applied to the field of honeycomb crispy original coconut chips, can solve the problems of difficult to develop fragrance, tough and chewy coconut chips, no market, etc., and achieve the effects of stable product quality, simple equipment and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

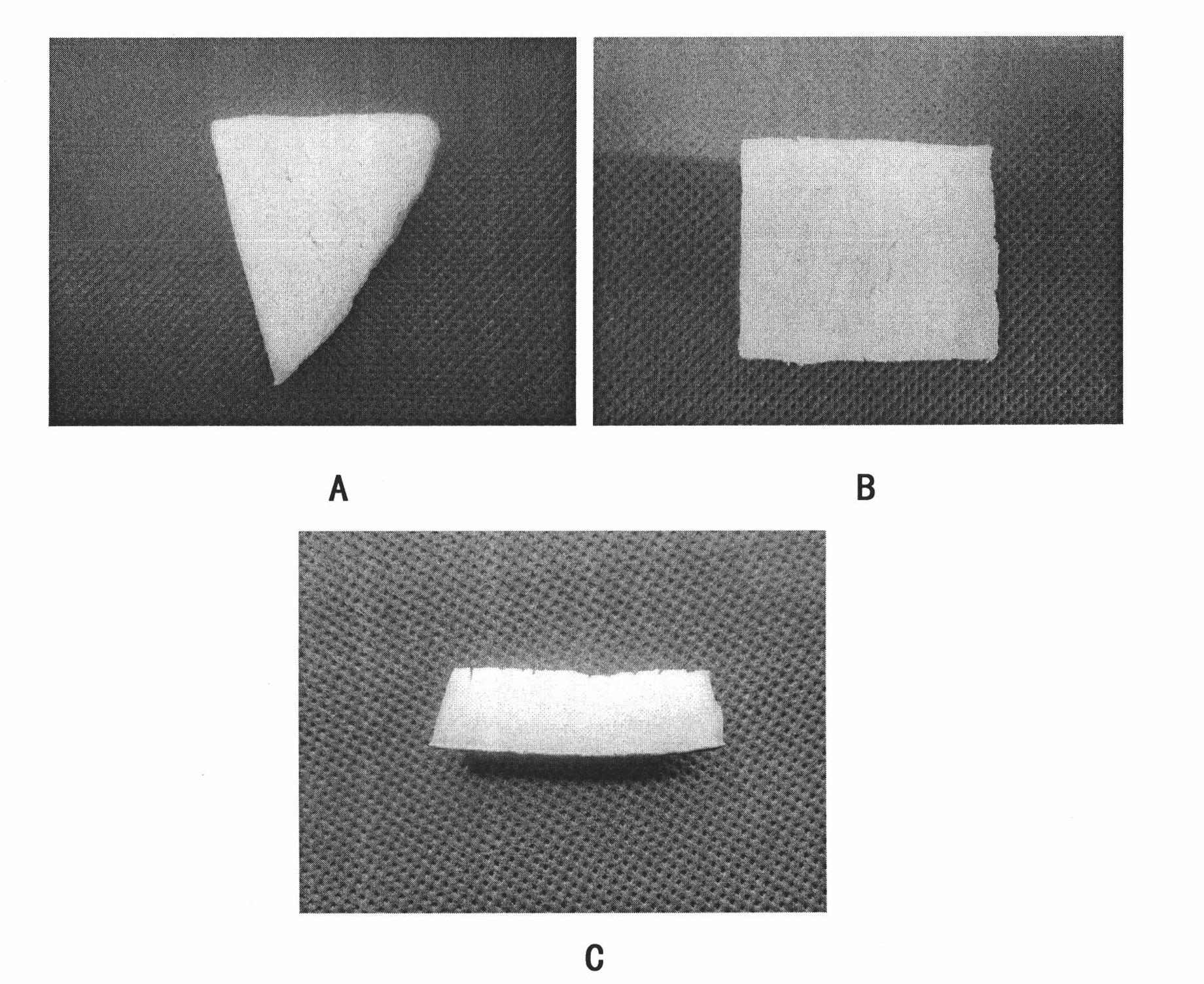

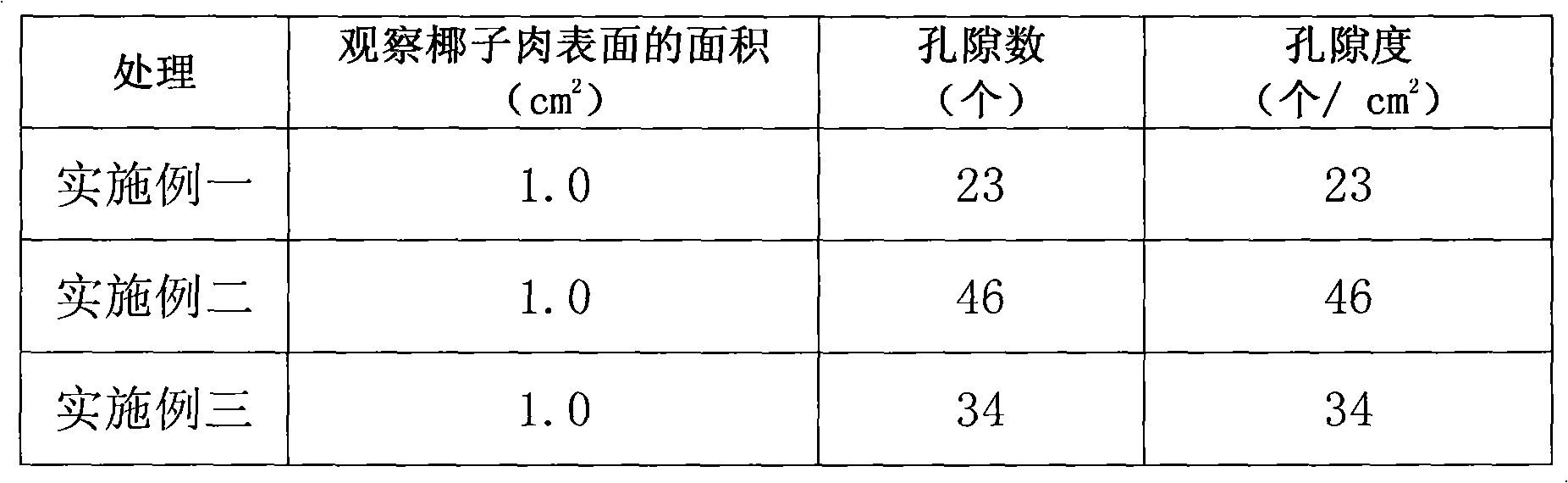

[0016] The coconut meat is cleaned, cut into triangular coconut flakes, put into the freezer and carry out quick freezing at -5°C for 13 hours, take it out, and at this time, the surface of the coconut meat presents many honeycomb-shaped irregular pores ( figure 1 A), the surface pores of coconut meat are randomly counted and measured (the results are shown in Table 1). Dry the coconut meat in an oven at 90°C for 2 hours, take out the syrup (the sugar content is adjusted according to the taste), put it in the oven and adjust it to 180°C, and bake for 15 minutes until the surface of the coconut flakes is golden Yellow and crispy in texture, take it out, balance the temperature to room temperature, and get sweet honeycomb-shaped crispy original coconut chips, packaged.

Embodiment 2

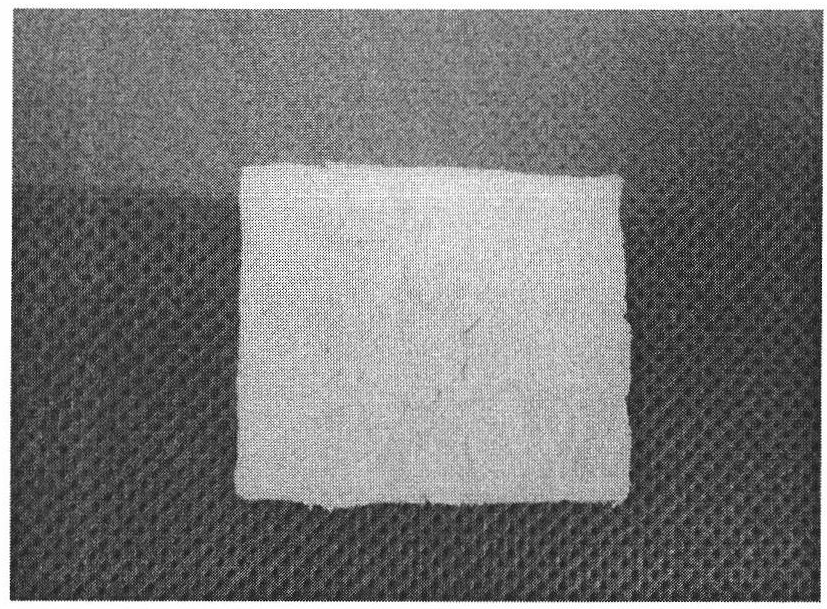

[0018] The coconut meat is cleaned, cut into square coconut flakes, put into the freezer and carry out -10 ℃ quick freezing for 8 hours, take it out, and now the surface of the coconut meat presents many honeycomb irregular pores ( figure 1 B), carry out random count measurement to the surface porosity of coconut meat (results are shown in Table 1). Dry the coconut meat in an oven at 100°C for 1 hour, take out the syrup (the sugar content is adjusted according to the taste), put it in the oven and adjust it to 190°C, and bake for 10 minutes until the surface of the coconut flakes is golden Yellow and crispy in texture, take it out, balance the temperature to room temperature, and get sweet honeycomb-shaped crispy original coconut chips, packaged.

Embodiment 3

[0020] Clean the coconut meat, cut it into small pieces of coconut flakes, put it in the freezer for quick freezing at -15°C for 6 hours, and take it out. At this time, the surface of the coconut meat presents many honeycomb-shaped irregular pores. Random count measurements (results in Table 1). Dry the coconut meat in an oven at 95°C for 2 hours, take it out, then put it in the oven and adjust it to 200°C, bake for 8 minutes, bake until the surface of the coconut flakes is golden yellow and the texture is crispy, take it out, Equilibrate the temperature to normal temperature to obtain the original flavor nest-shaped crunchy original flavor coconut chips, and pack them.

[0021] The surface of the coconut meat after the quick-freezing treatment was observed, and it was found that the surface of the coconut meat after the quick-freezing treatment showed many honeycomb-shaped irregular pores. Take pictures of the test samples and display them (see figure 1 A, B, C), although t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com