Oxygen absorber, oxygen absorbent resin composition, and oxygen absorbent film

An oxygen absorbing agent, thermoplastic resin technology, applied in the field of oxygen absorbing film, oxygen absorbing agent and oxygen absorbing resin composition, can solve the problem of not being suitable for use in dry food, achieve small ignition possibility, wide application range, Excellent safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

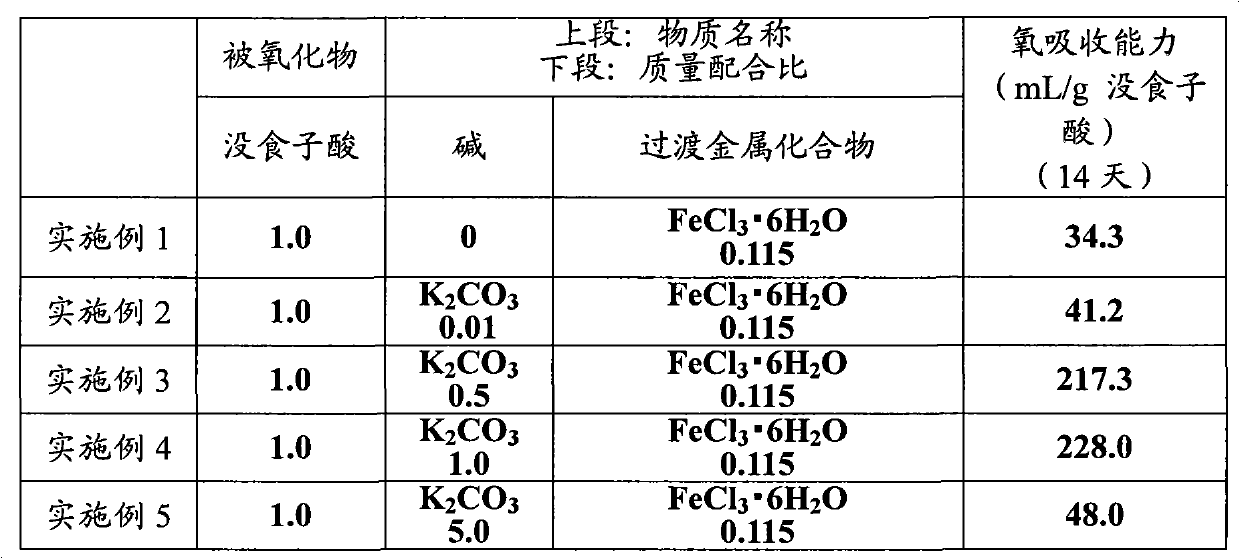

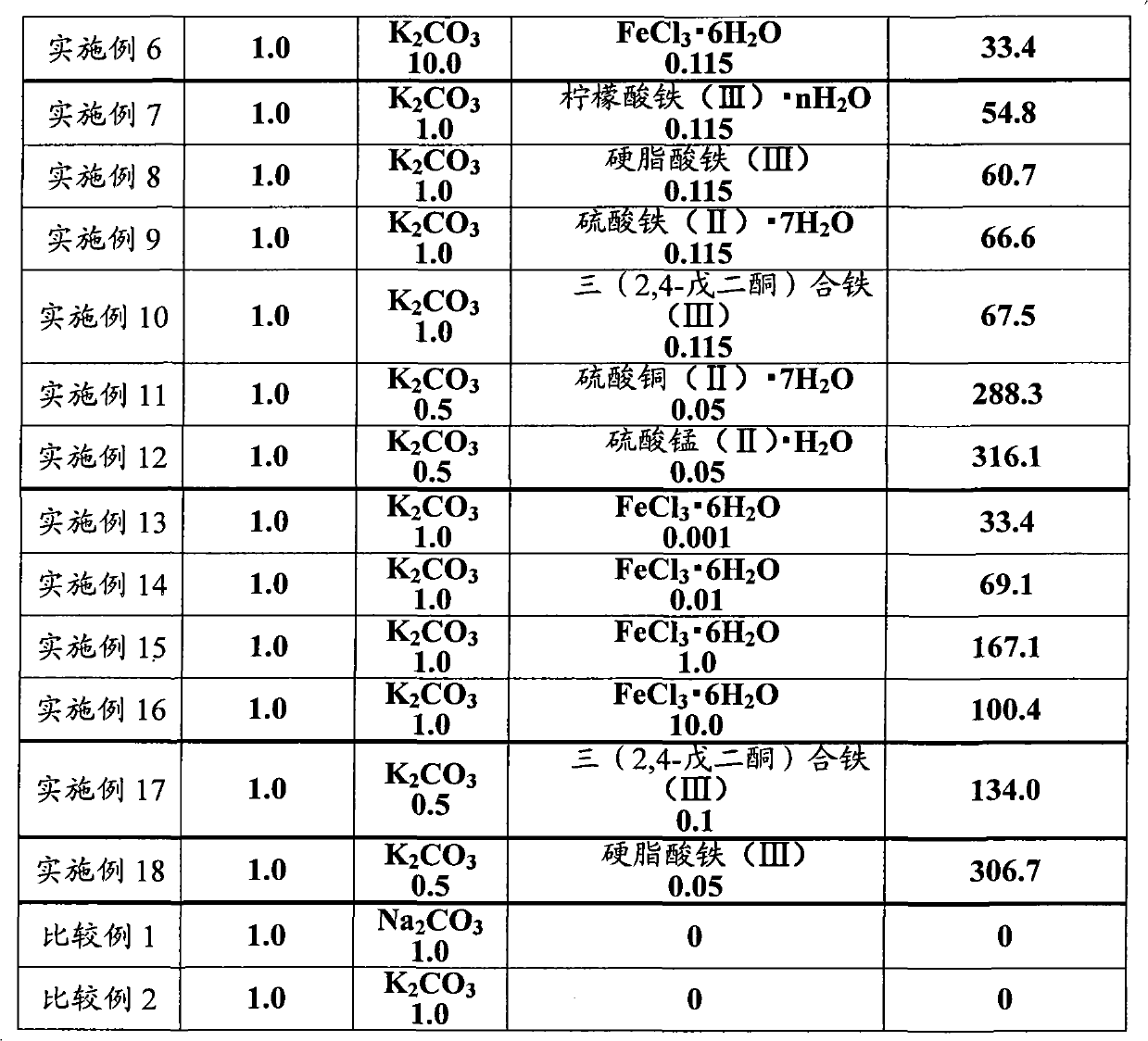

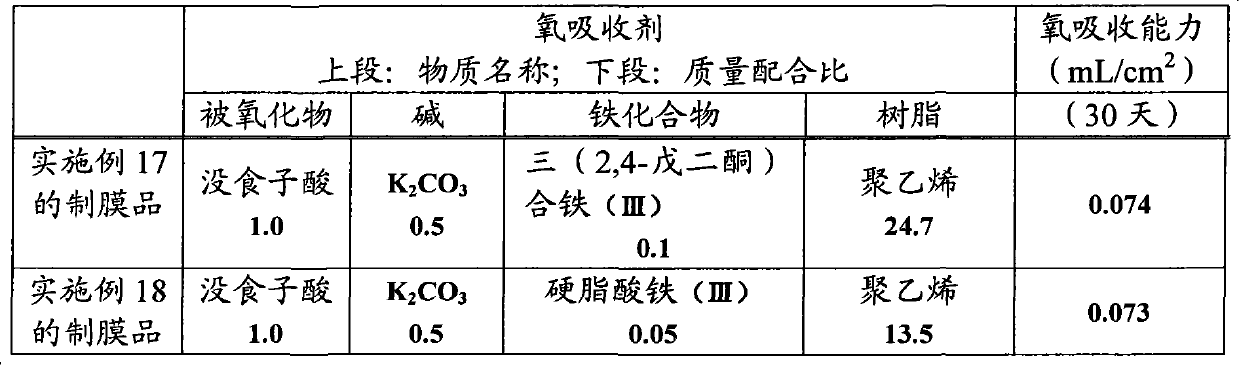

[0031] Relative to 5 g of gallic acid (which is expressed as 1.0 in terms of mass ratio in Table 1), mix the transition metal compound and the carbonic acid-based basic compound in the proportions shown in Table 1, and mix rapidly with a mortar until each particle is thin and uniform. until. The obtained sample was subdivided so that the amount of gallic acid might be 0.05 g in an aluminum laminate packaging bag in which nylon / aluminum foil / polyethylene was laminated. After the oxygen absorber was charged, it was heat-sealed into a square bag type and sealed so that the volume (air volume) of the packaging bag was 106 milliliters (mL). After storage at room temperature for 14 days, the oxygen concentration in the air in the packaging bag was measured, and the oxygen absorption capacity of the oxygen absorber was calculated (Examples 1 to 18).

[0032] For comparison, an oxygen absorber containing no transition metal compound and containing gallic acid and a carbonic acid-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com