Method of operation of tooth or profile grinding machine and tooth or profile grinding machine

A grinding machine, preforming technology, applied in the direction of grinding machine parts, components with teeth, gear teeth manufacturing devices, etc., can solve problems such as unsatisfactory proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

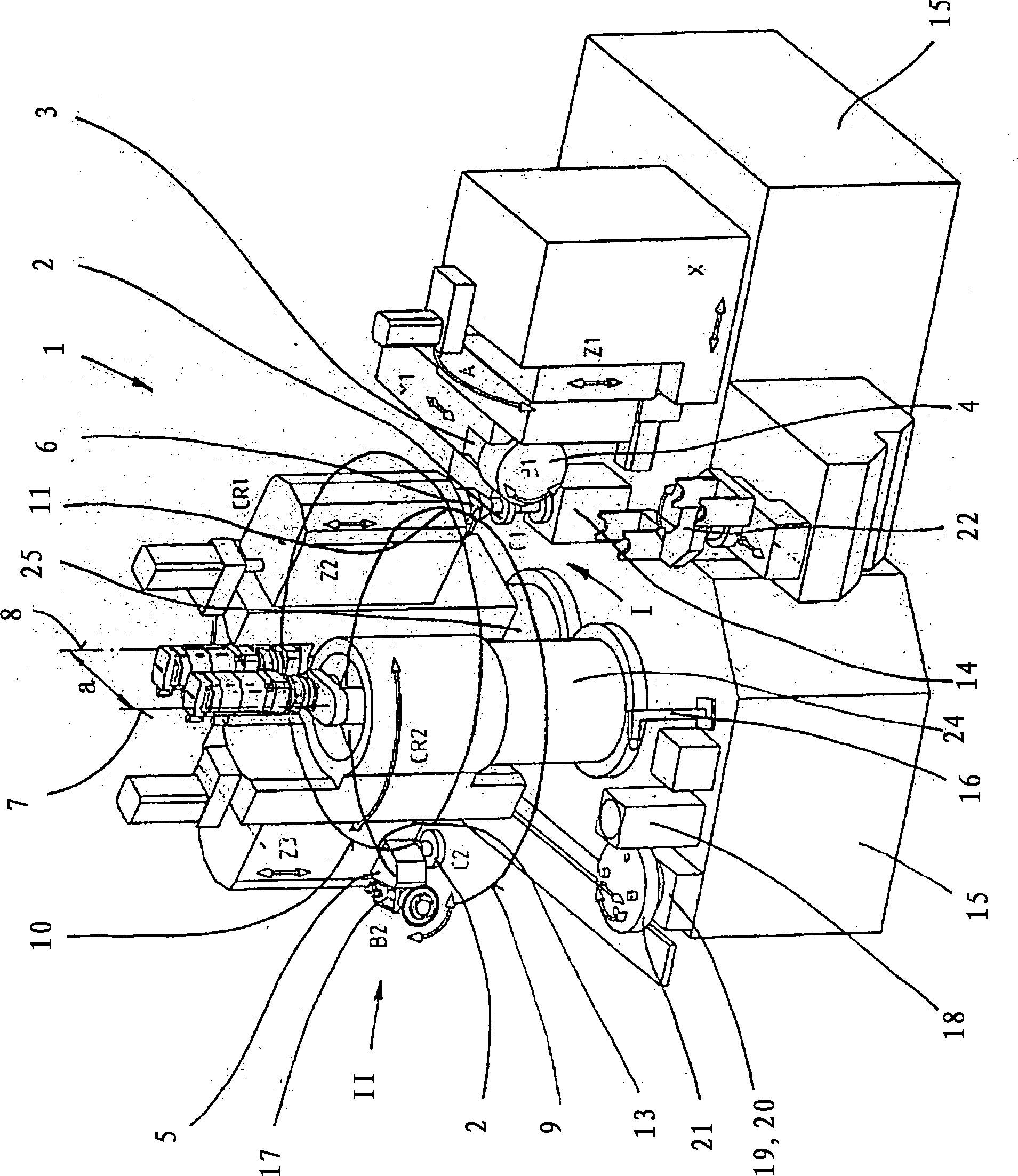

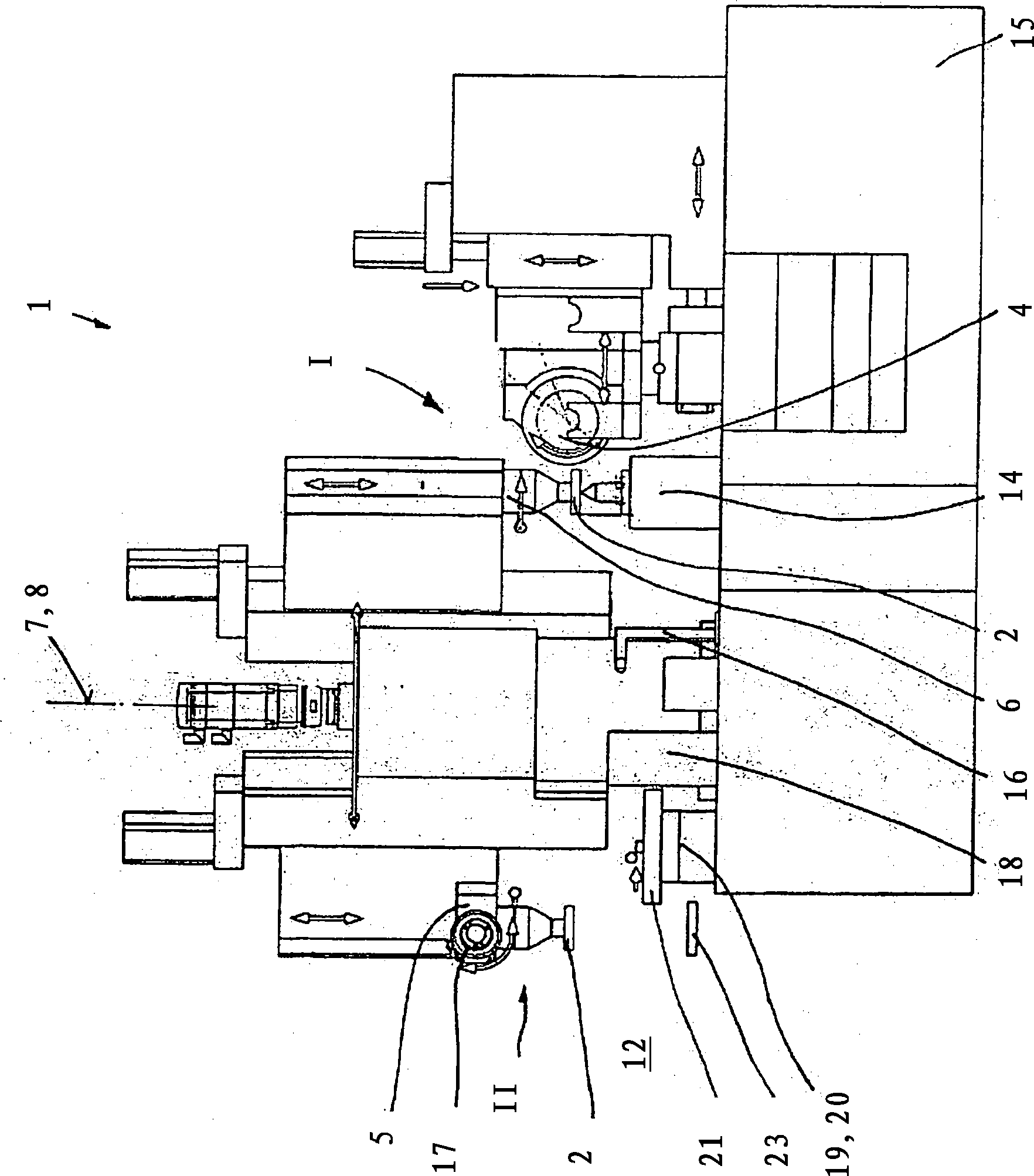

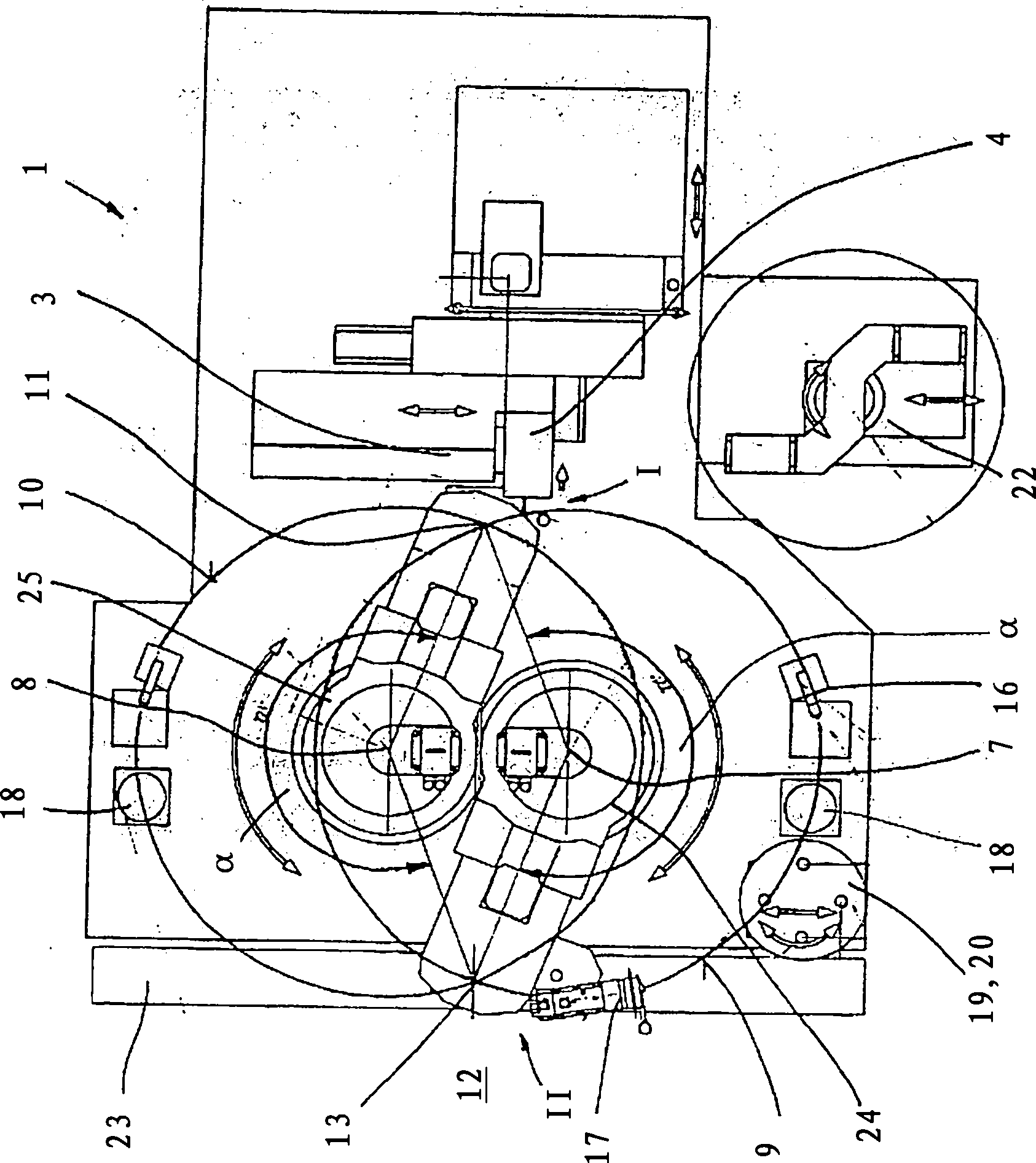

[0032] exist Figures 1 to 3 A first embodiment of the gear grinding machine 1 is shown in . The grinding machine 1 has a bed 15 on which the usual elements are first arranged in order to be able to carry out the grinding operation. Accordingly, the grinding machine 1 has, in particular, a tool spindle 3 comprising a grinding tool 4 (grinding wheel or grinding worm, optionally also offset in axial direction with several grinding tools for roughing and finishing), the tool spindle 3 is arranged on the corresponding movable guide rail, so that it can implement the movement required for the grinding process. The provided direction of movement is indicated in the figures by double arrows. However, this will not be discussed in more detail, since the usual axes are involved here.

[0033] However, it is not typical for gear grinding machines to provide two workpiece spindles 5 and 6 which are each designed to receive a workpiece 2 . The two workpiece spindles 5 , 6 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com