Internal heating type multi-cavity hot runner mold

A multi-cavity, hot runner technology, applied in the field of plastic injection molding molds, can solve the problems of easy condensation of the melt and easy blockage of the gate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

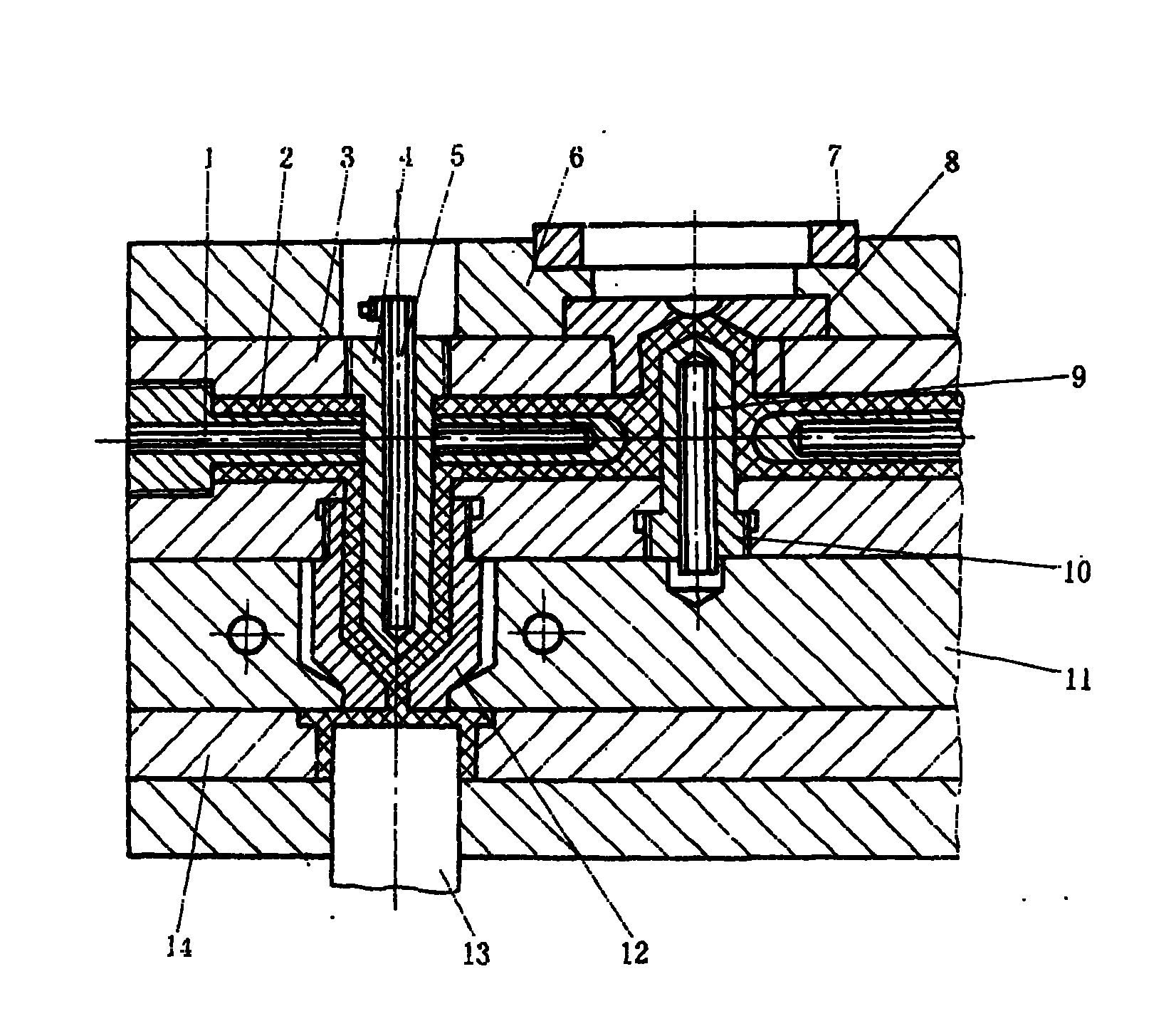

[0010] The figure shows a hot runner injection mold with internal heating and multiple cavities. It is equipped with a heater in the entire runner, and a rod-shaped heater is also installed inside the nozzle, and extends to the center of the gate, that is, the entire gating system is heated. Its thermal insulation is based on the condensation layer formed by the contact between the melt and the mold. Such a flow channel has low heat loss and high thermal efficiency, and will not solidify even if the molding cycle is long. At the same time, the diameter of the flow channel is larger to facilitate the placement of the heater, and the flow channel is arranged in a staggered way. On the other hand, this mechanism is not only suitable for single-point feeding, but also can be used for multi-point feeding of large products. In addition, in order to avoid drooling when injecting low-viscosity plastics, the mold is specially designed with a valve gate device. At the same time, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com