Device for preventing backflow of vacuum extract on screw extruder

A screw extruder and extraction technology, applied in the field of improvement mechanism, can solve problems such as incomplete separation of impurities, product discoloration, quality problems, etc., and achieve the effects of preventing accidental scalding, obvious effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

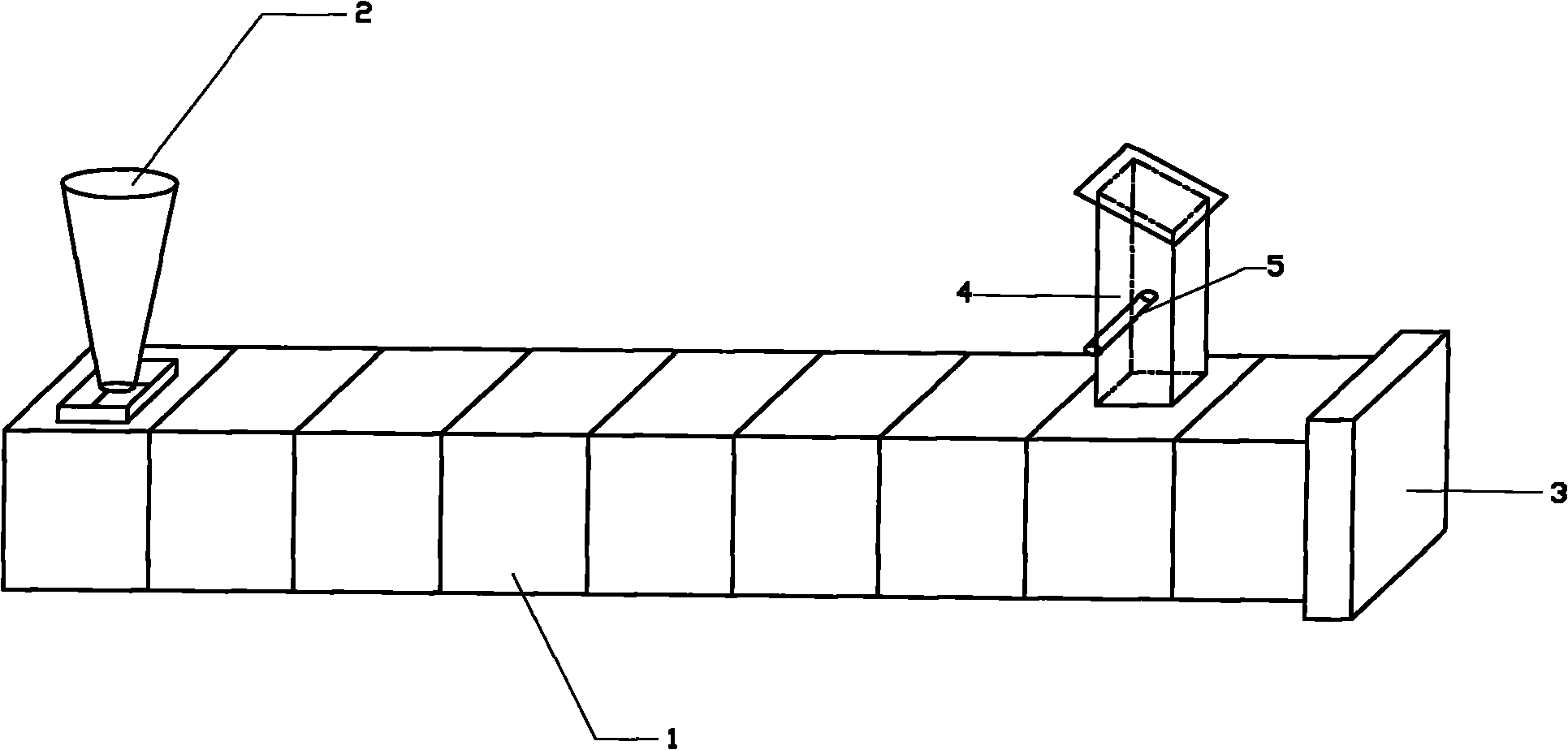

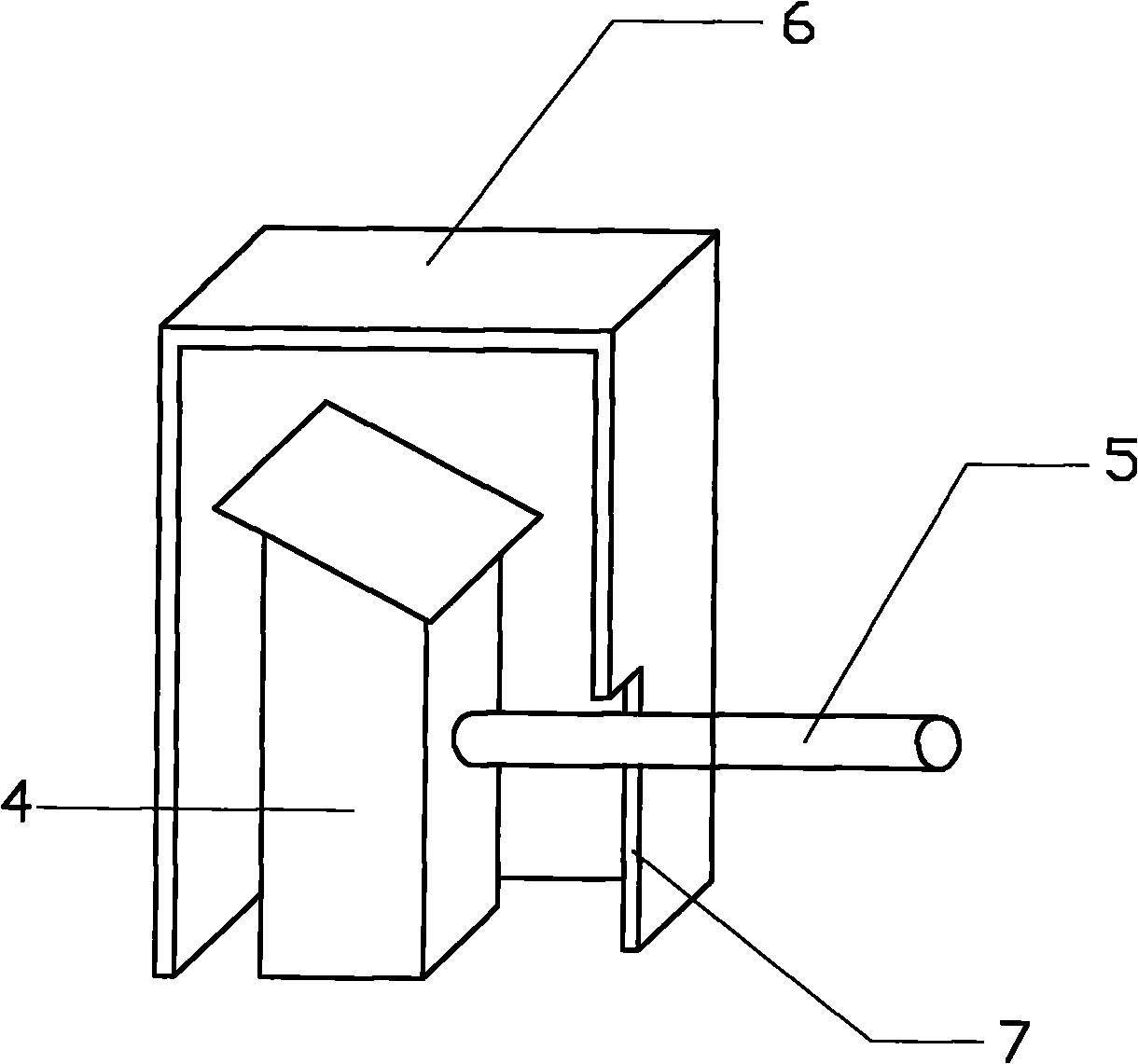

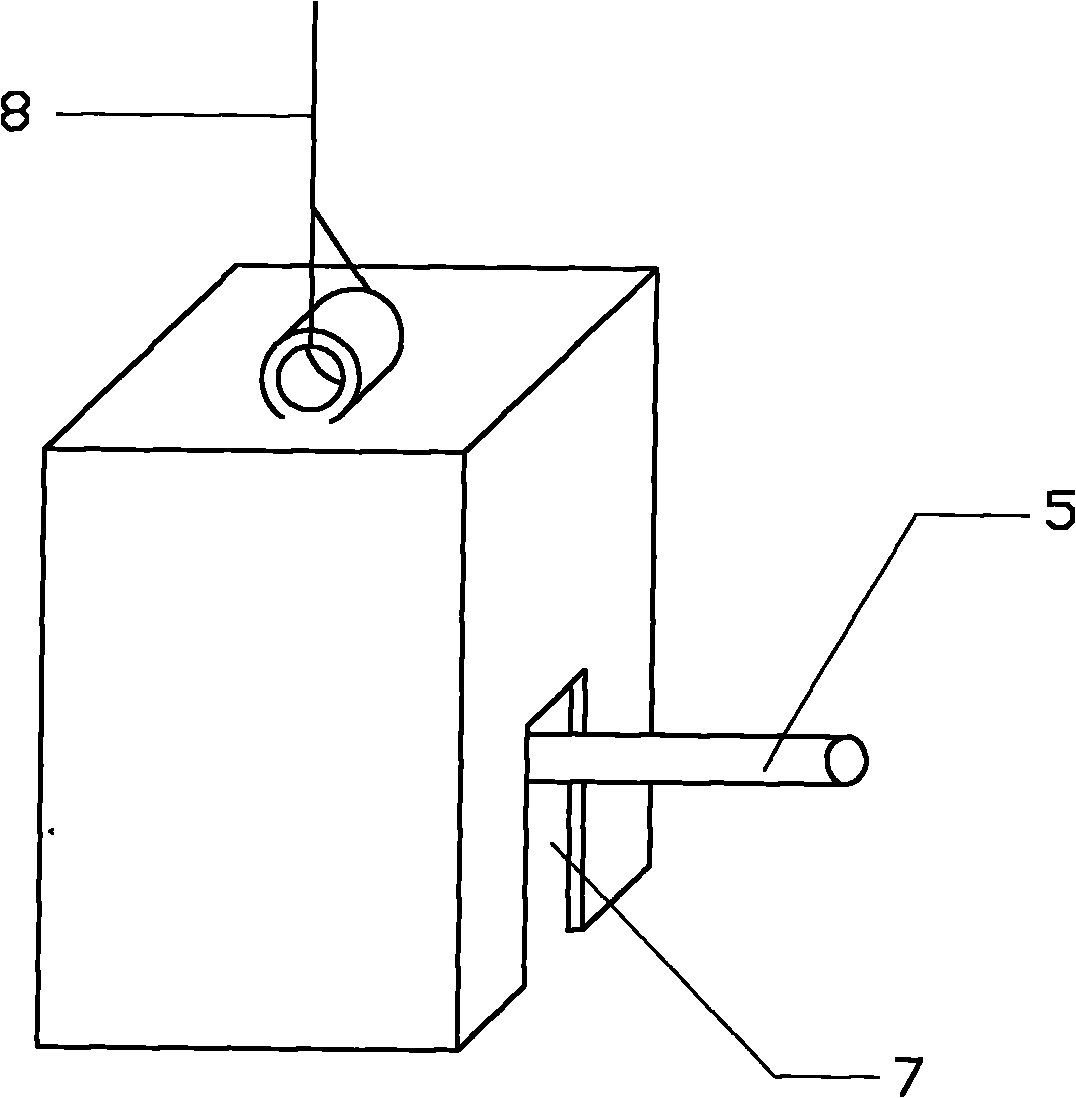

[0024] A device on a screw extruder to prevent the reflux of vacuum extracts, the screw extruder includes a screw barrel 1, one end of the screw barrel 1 is a feed end 2, the other end is a discharge end 3, and the end close to the discharge end 3 The top of the screw barrel 1 is provided with a vacuum chamber 4 whose bottom communicates with the screw barrel 1. There is a vacuum tube connection port 5 connected to the vacuum tube on the vacuum chamber 4. A heating chamber 6 is arranged outside the vacuum chamber 4. A heating plate is installed on the inner wall of the heating chamber. A heating resistor is arranged in the heating sheet, and the heating resistor is connected to the heating power supply through a temperature controller, and the probe of the temperature controller extends into the heating chamber 6, and the heating chamber 6 is provided with a heating chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com