Retarding control system for mining dumper

A mining dump truck and control system technology, which is applied in the direction of control/regulation system, control device, non-electric variable control, etc., can solve the problems of limited vehicle speed, inconvenient operation, high maintenance cost, etc., to improve safety, The effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

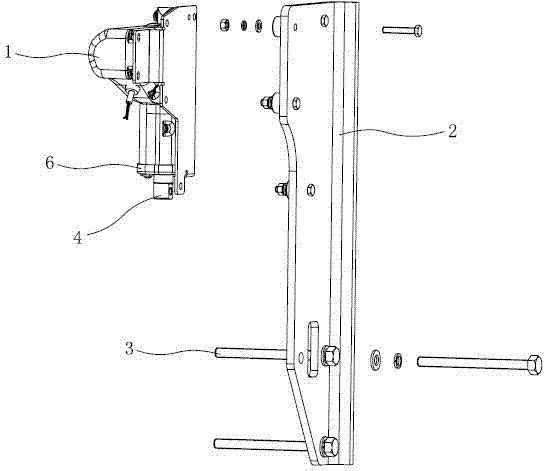

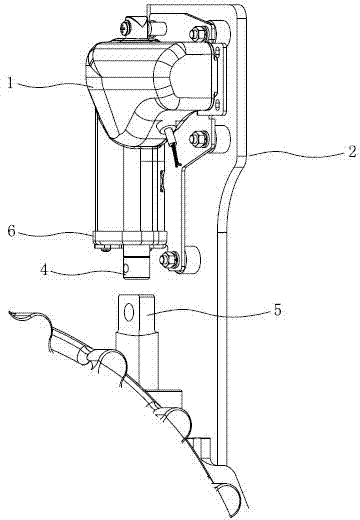

[0020] Embodiment one: see figure 1 , 2 As shown, a slow-moving control system for mining dump trucks includes a slow-moving control assembly arranged on the mining dump truck. The slow-moving control assembly is provided with a slow-moving actuator 1 and a fixed bracket 2. The slow-moving The actuator 1 is connected to the fixed bracket 2, and the fixed bracket 2 is fixedly connected to the mining dump truck through bolts 3. The slow-moving actuator 1 includes a housing in which a motor is arranged, and the output shaft of the motor is decelerated The mechanism is connected with the push rod 4, and the outer end of the push rod 4 is in conflict with the slow-moving valve rod 5 of the gearbox. The clutch and braking mechanism are also equipped with a slow-moving control switch in cooperation with the slow-moving actuator 1. The slow-moving control switch is a seesaw switch, and the slow-moving actuator is provided with a built-in switch at the end of the clutch and the push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com