Heat transfer plug and production process thereof

A preparation process and thermal transfer technology, applied in the field of thermal transfer plug preparation technology, can solve the problems of heat resistance, easy fading, and durability on the surface, and achieve strong adhesion, good printing repeatability, and no environment. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

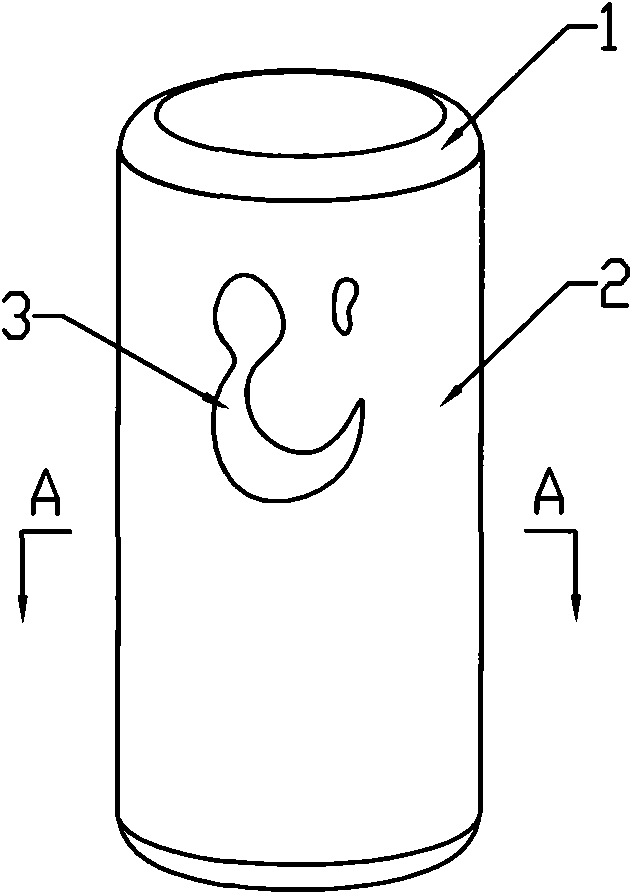

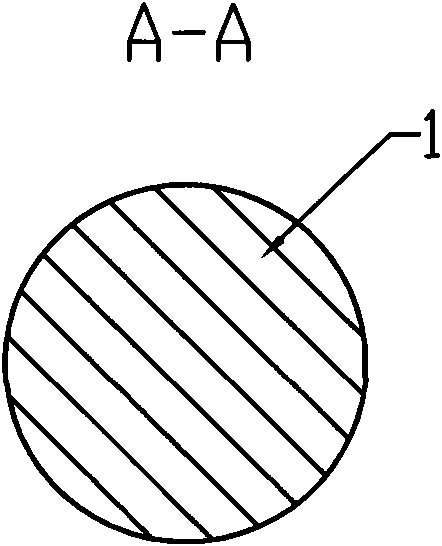

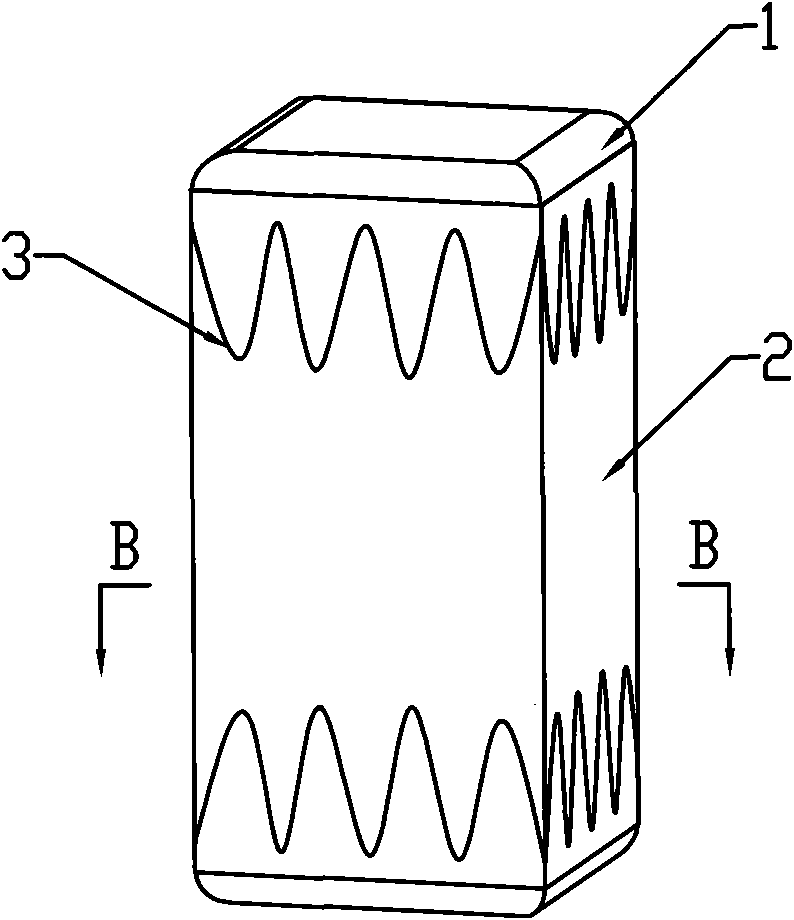

[0038] Thermal transfer plug of the present invention, such as Figure 1A and Figure 2A As shown, it includes a plug body 1 and a thermal transfer layer 2, the thermal transfer layer 2 is consolidated with the surface of the plug body 1, and the pattern, color or texture on the thermal transfer layer 2 is thermally transferred to the plug body 1 on the surface. Preferably, the plug body has a smooth surface made of polymer material, and the pattern, color or texture on the thermal transfer layer is thermally transferred onto the smooth surface.

[0039] Such as Figure 1A and Figure 1B As shown, the plug body is a cylindrical plug made of polymer material with a circular cross section, and it can also be made into a cylindrical plug with an oval or almost circular cross section.

[0040] Such as Figure 2A and Figure 2B As shown, the plug body is a cylindrical plug made of polymer material with a square cross-section, and it can also be made into a cylindrical plug with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com