Bent pipe heating type coal substance decomposer

A heating type and material technology, which is applied in the heating of coke ovens, indirect heating and dry distillation, and combustible gas heating coke ovens, etc., can solve the problems of inability to be uniformly heated, decomposed, low in added value, and waste of resources and the environment, and achieves improved utilization. efficiency and utilization levels, saving and utilizing energy, improving the effectiveness of activity paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

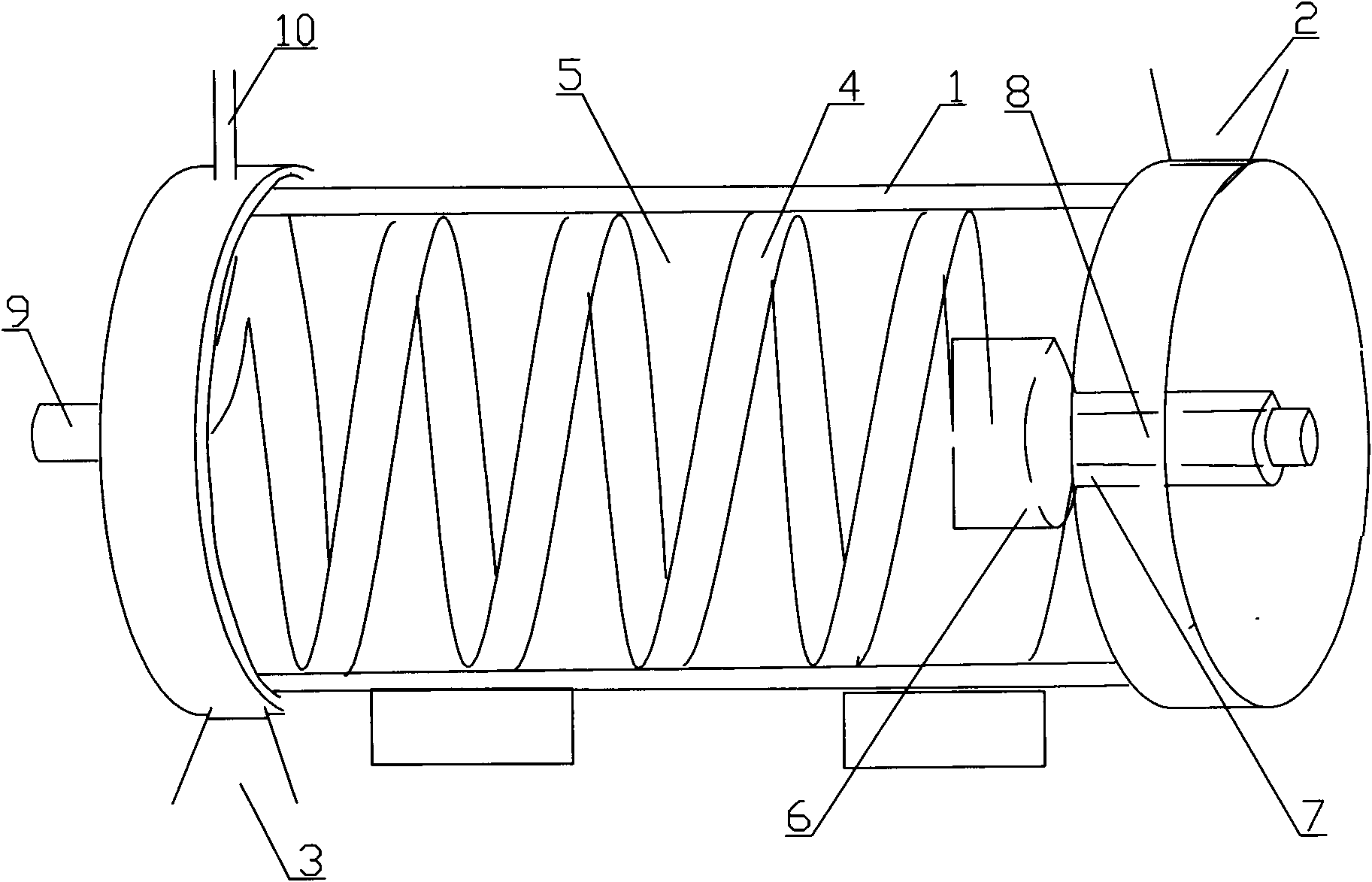

[0017] Such as figure 1 Shown: a curved tube heating type coal decomposition device, including a closed rotary kiln body 1 with a feed port 2 and a discharge port 3, the kiln body 1 is provided with a flame gas pipeline heating mechanism 4, the The coal substance propelling decomposition channel formed between the flame gas pipeline heating mechanism 4 and the inner wall of the kiln body 1, the coal decomposition gas collection pipe 10 communicating with the coal substance propelling decomposition channel is arranged on the kiln body 1, and the flame gas pipeline heating mechanism It includes a fuel supply pipe 8, an air supply pipe 7, a combustion chamber 6 and a flame heat dissipation pipe 5. The flame heat dissipation pipe is a spiral pipe, and the outer circumference of the spiral pipe is arranged on the inner wall of the kiln body 1. The spiral pipe can be a plurality of close-packed pipes. The section of the spiral pipe is polygonal or circular.

Embodiment 2

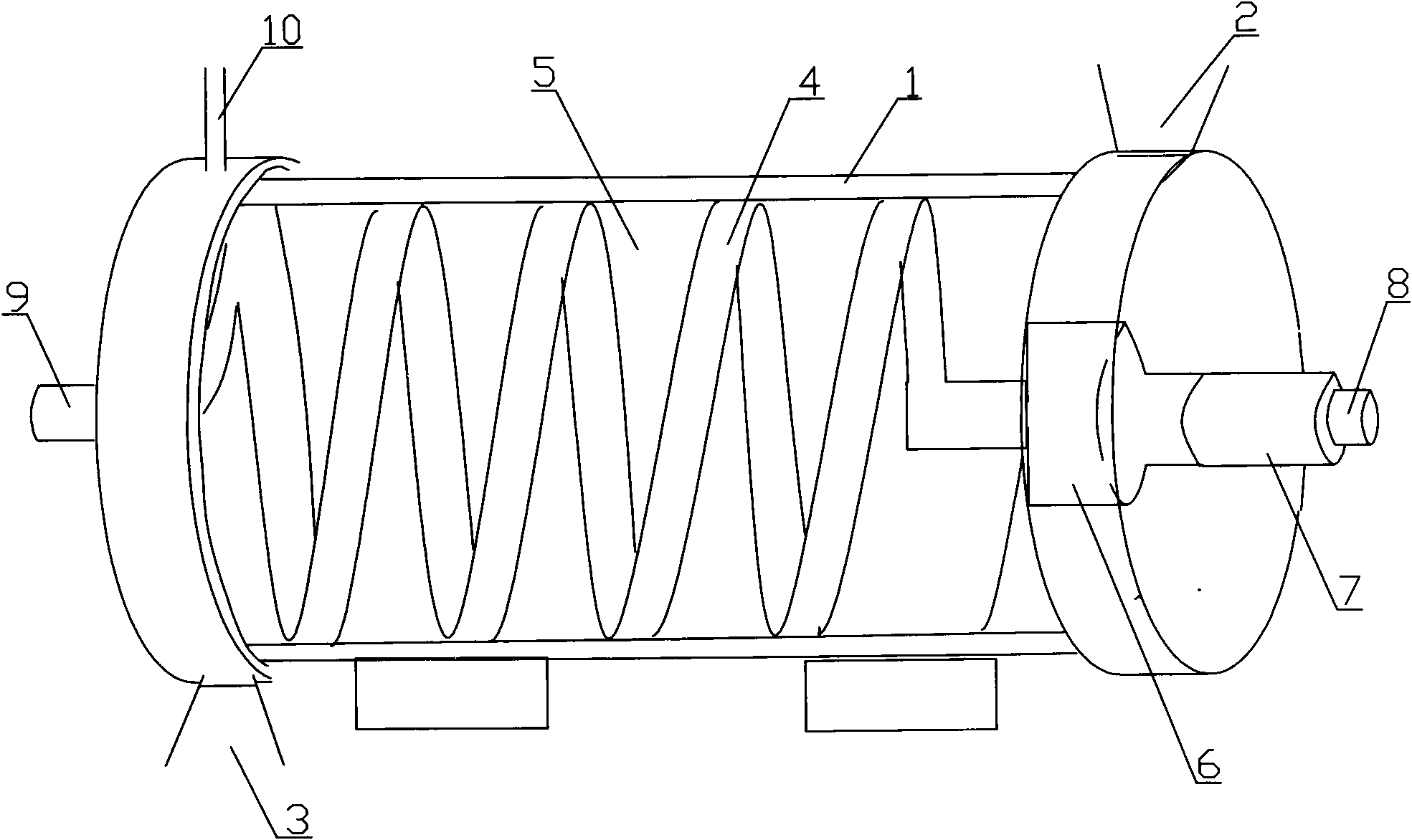

[0019] Such as figure 2 Shown: a curved tube heating type coal decomposition device, including a closed rotary kiln body 1 with a feed port 2 and a discharge port 3, the kiln body 1 is provided with a flame gas pipeline heating mechanism 4, the The coal substance propelling decomposition channel formed between the flame gas pipeline heating mechanism 4 and the inner wall of the kiln body 1, the coal decomposition gas collection pipe 10 communicating with the coal substance propelling decomposition channel is arranged on the kiln body 1, and the flame gas pipeline heating mechanism It includes a combustion chamber 6 and a flame heat dissipation pipe 5. The combustion chamber 6 communicates with the fuel supply pipe 8 and the air supply pipe 7 arranged outside the kiln body 1. The flame heat dissipation pipe is a spiral pipe, and the spiral pipe outside The circumference is set on the inner wall of the kiln body 1 . The spiral pipe can be a plurality of close-packed pipes. Th...

Embodiment 3

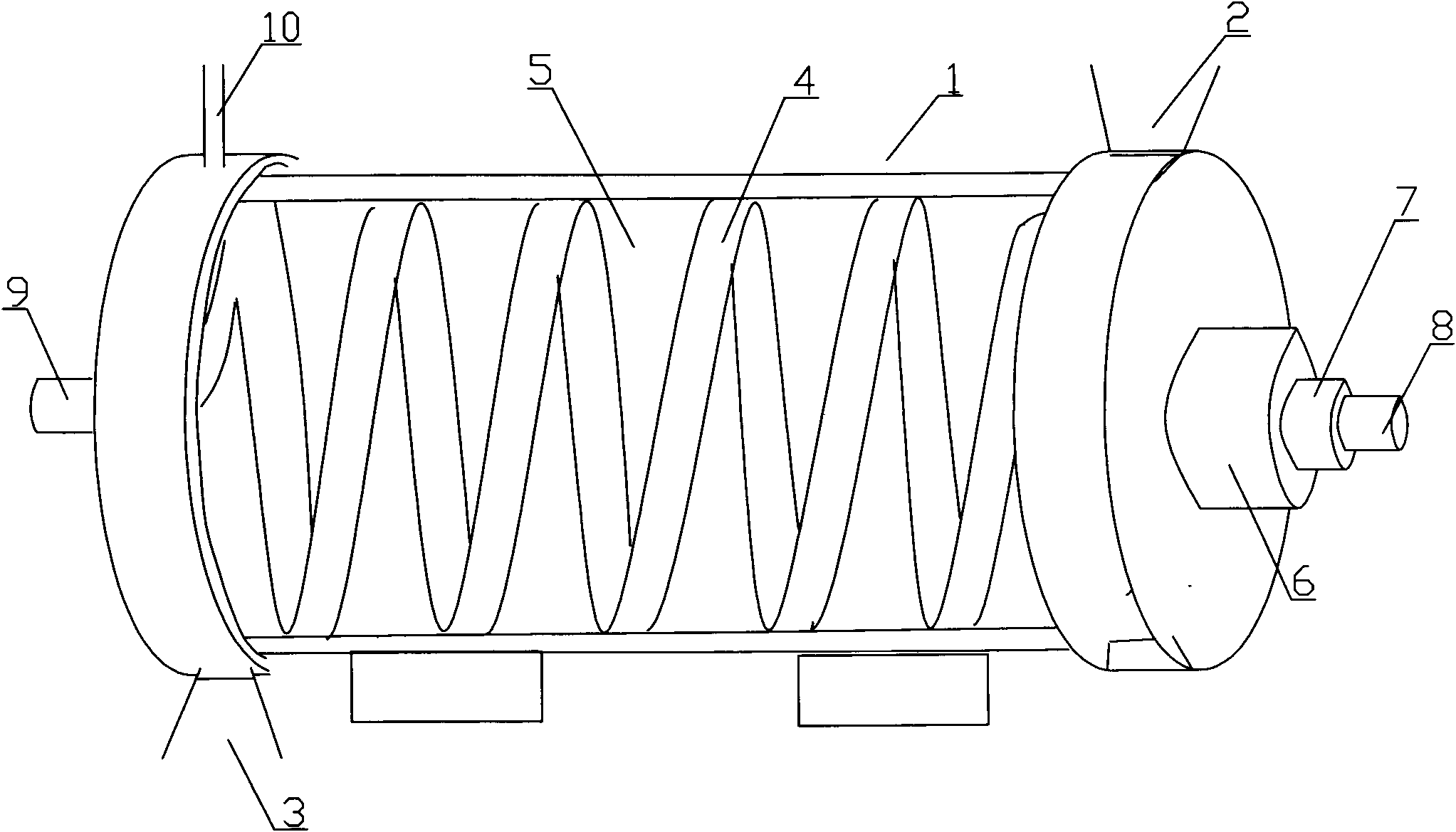

[0021] Such as image 3 Shown: a curved tube heating type coal decomposition device, including a closed rotary kiln body 1 with a feed port 2 and a discharge port 3, the kiln body 1 is provided with a flame gas pipeline heating mechanism 4, the The coal substance propelling decomposition channel formed between the flame gas pipeline heating mechanism 4 and the inner wall of the kiln body 1, the coal decomposition gas collection pipe 10 communicating with the coal substance propelling decomposition channel is arranged on the kiln body 1, and the flame gas pipeline heating mechanism Including flame heat dissipation pipe 5, said flame heat dissipation pipe 5 is connected with combustion chamber 6, fuel supply pipe 8 and air supply pipe 7 arranged outside kiln body 1, said flame heat dissipation pipe 5 is a spiral pipe, said The outer circumference of the spiral pipe is arranged on the inner wall of the kiln. The spiral pipe can be a plurality of close-packed pipes. The section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com