Online prediction system for terminal composition of low-carbon ferrochromium in silicothermic smelting

A technology of low-carbon ferrochromium and electric silicon thermal method, which is applied in the field of submerged arc furnace smelting, can solve the problems of long training time and error of large data volume data samples, improve learning efficiency and regression ability, improve online prediction accuracy, The effect of accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

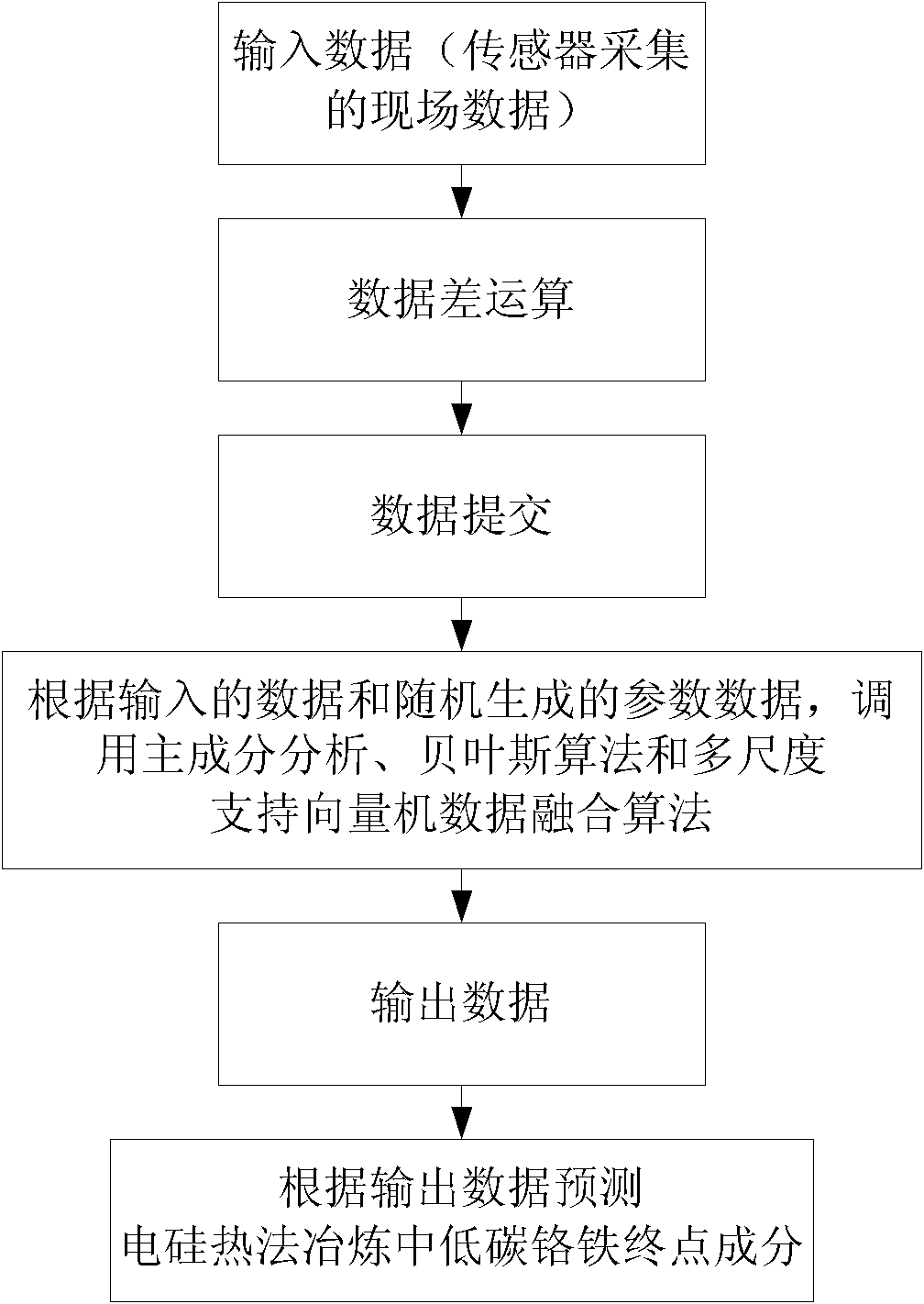

[0017] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

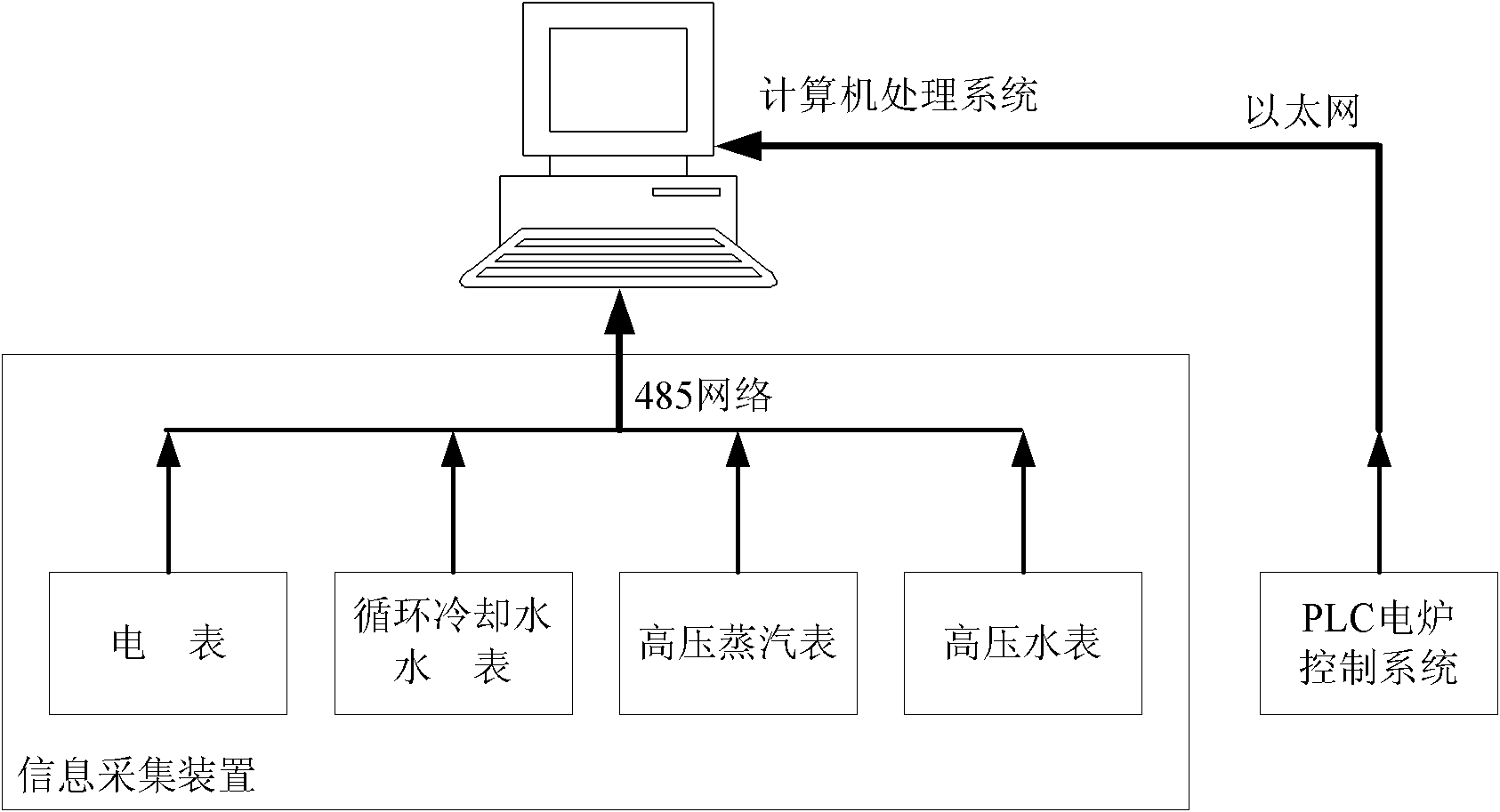

[0018] Such as figure 1 As shown, the on-line prediction system of low-carbon ferrochrome end-point composition in electro-silicothermal smelting of the present invention includes: an information acquisition device and a computer processing system composed of an electric meter, a water meter, a gas meter, and a PLC electric furnace control system. Among them, electricity meters, water meters, and gas meters communicate with the computer processing system through the 485 network, and the PLC electric furnace control system communicates with the computer processing system through Ethernet to realize data transmission.

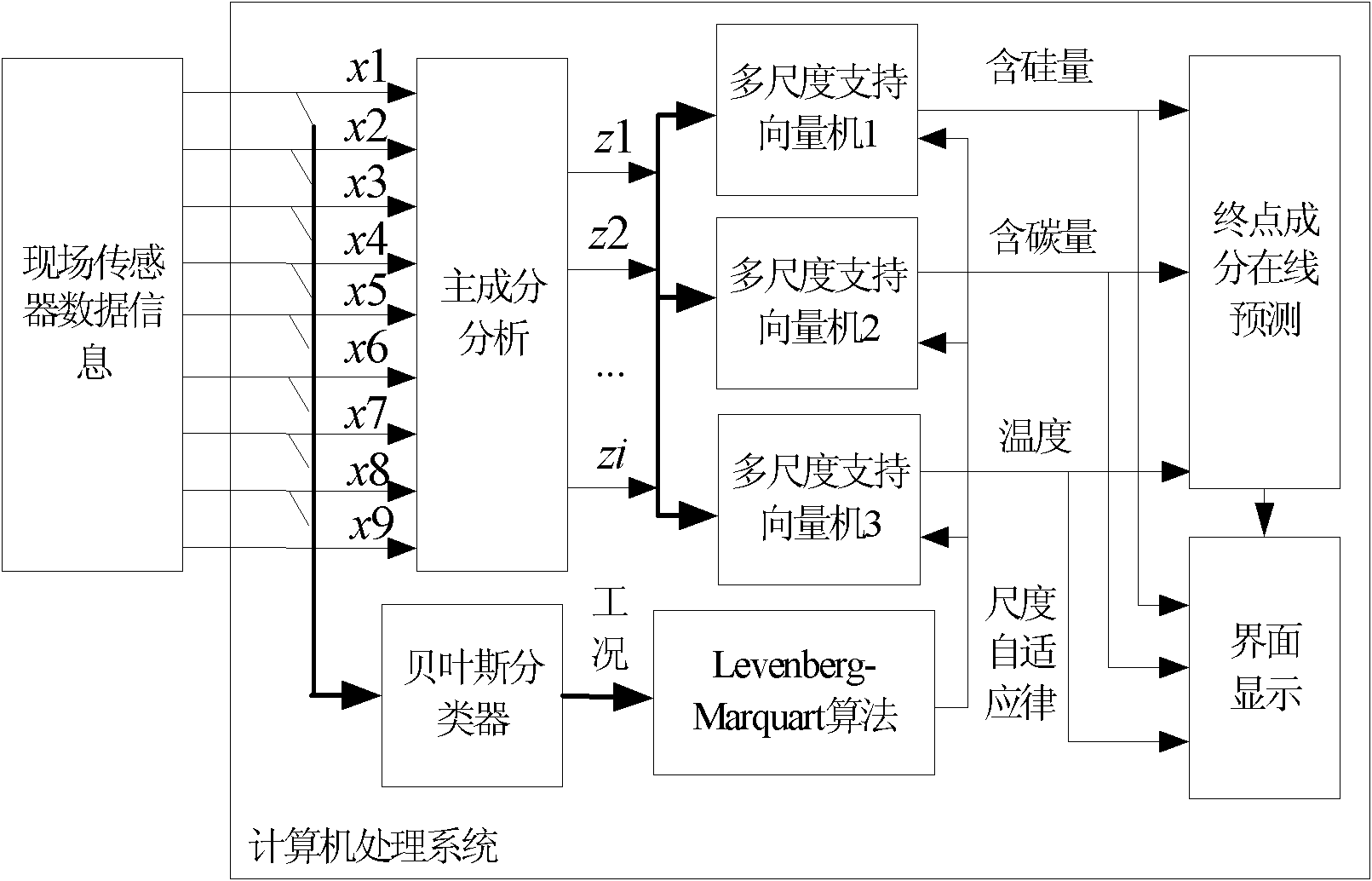

[0019] Such as figure 2 As shown, the online prediction system for the end-point composition of low-carbon ferrochrome in electro-silicothermal smelting of the present invention uses a computer processing system to complete the online end-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com