Water level monitoring method of washing machine and full-automatic washing machine

A fully automatic washing machine and water level monitoring technology, which is applied in the field of washing machines, can solve problems such as misjudgment, over-protection, and floor damage, and achieve the effect of solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

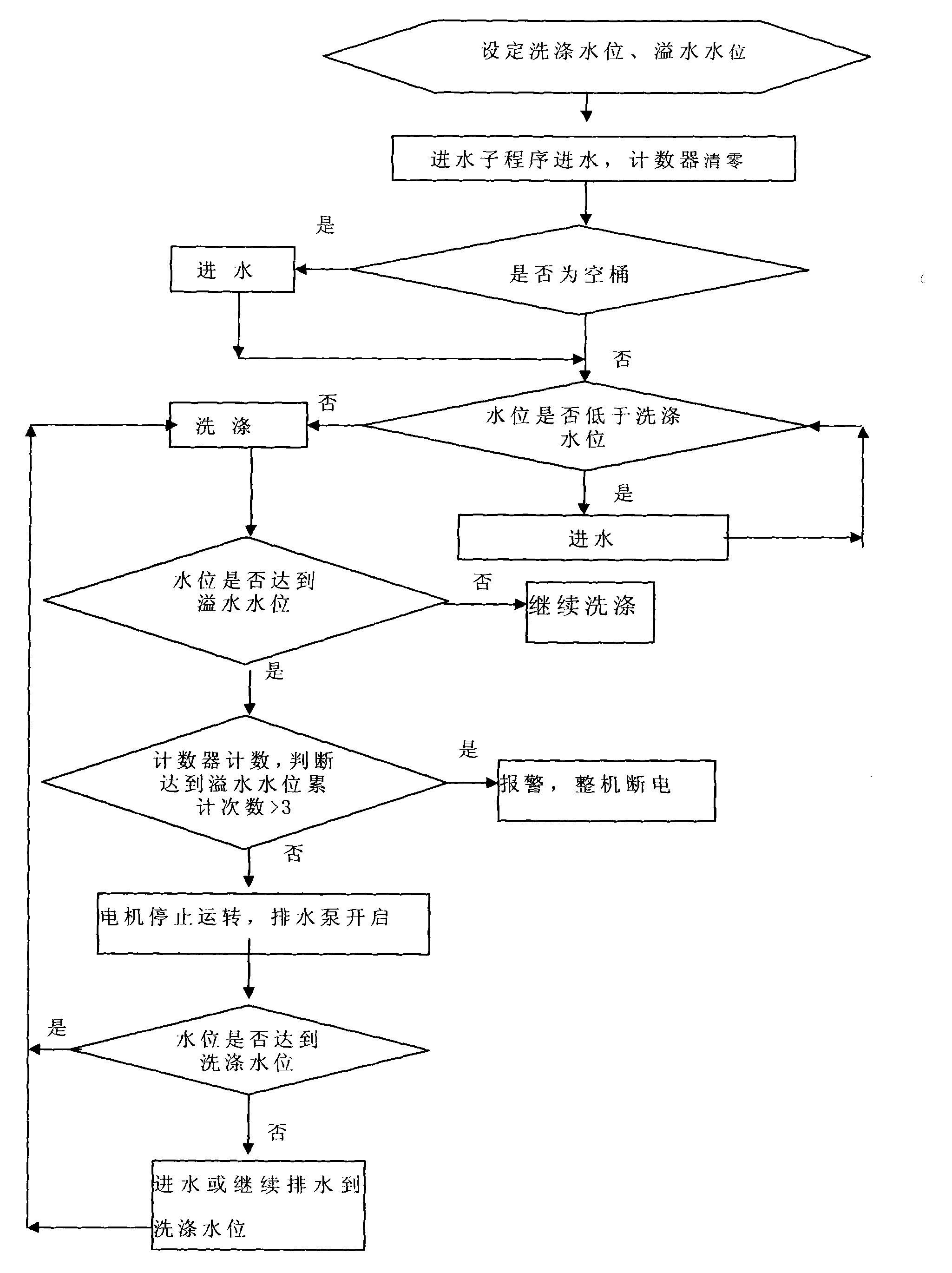

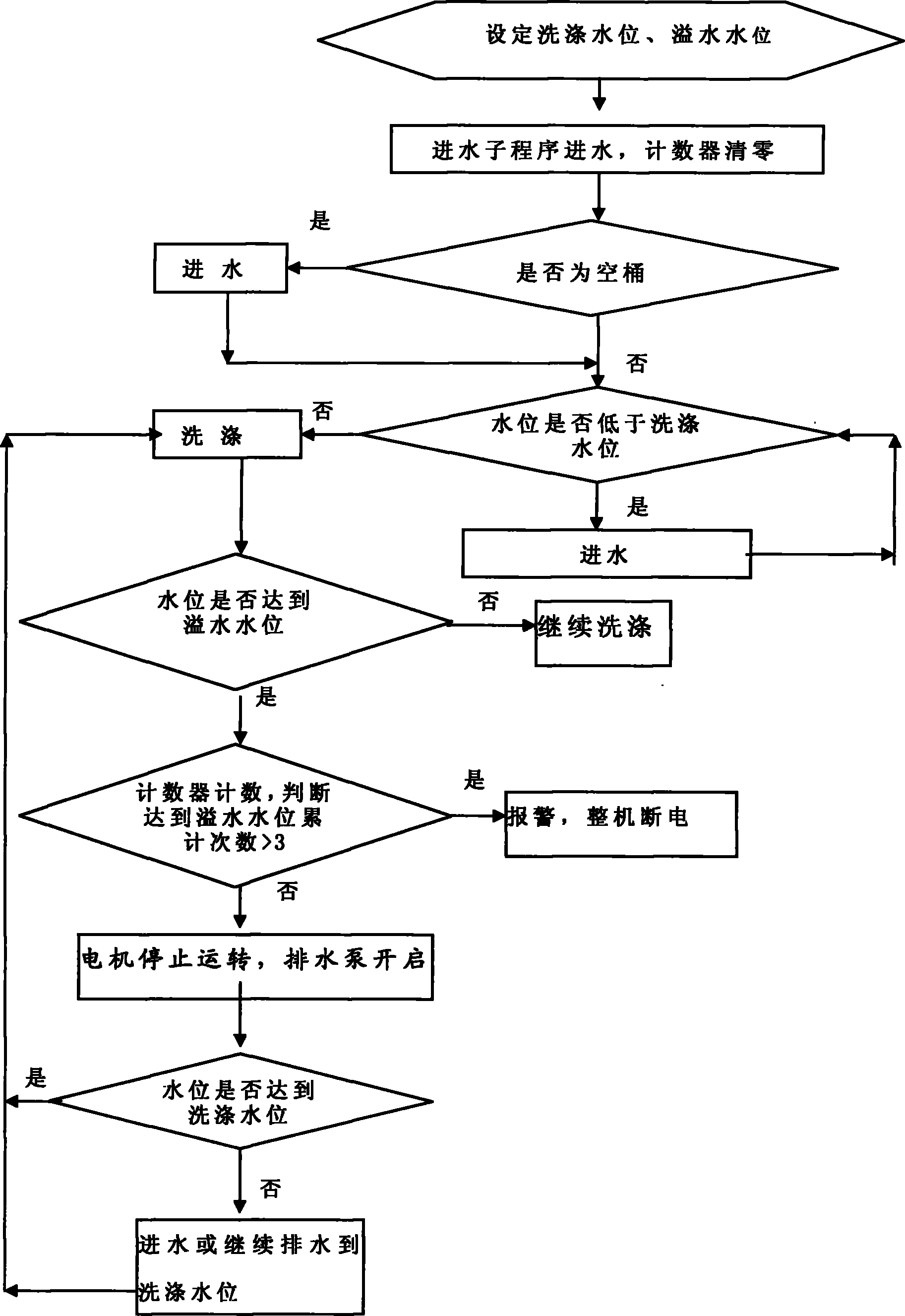

[0021] The water level monitoring method provided by the present invention and the fully automatic washing machine using the water level monitoring method will be described in detail below with reference to the accompanying drawings.

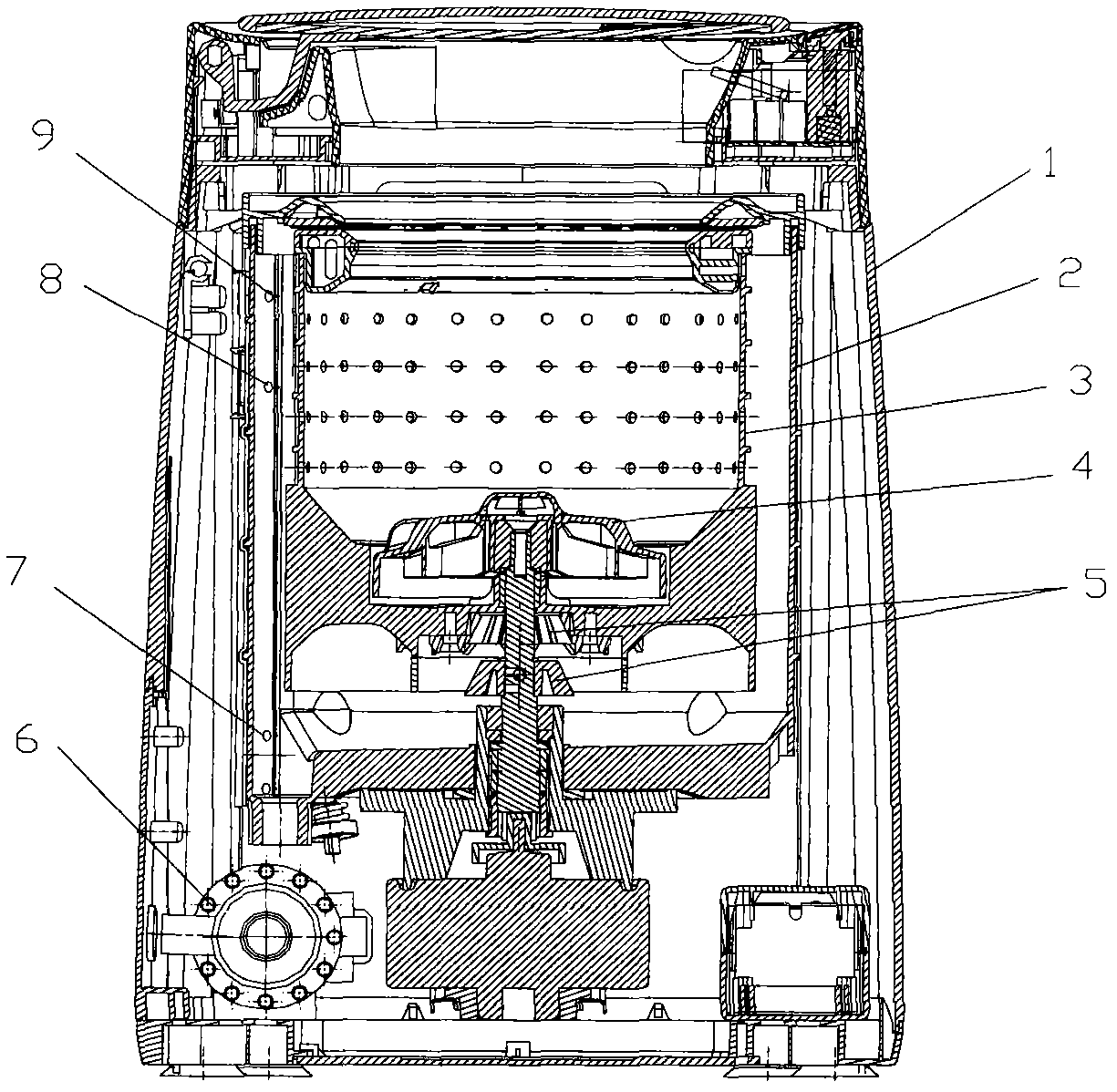

[0022] see figure 1 , shows a schematic structural view of the washing machine in this embodiment. The washing machine comprises a casing 1, an outer tub 2, an inner tub 3, a pulsator 4, a clutch device 5, a drainage pump 6, a reset water level 7, a washing water level 8, and an overflow water level 9. The motor shaft of the washing machine directly transmits power to the pulsator, and the clutch device is composed of internal and external splines. The internal splines are fixed on the bottom of the inner tub, and the external splines are fixed on the motor shaft. When the fully automatic washing machine is washing, the inner cylinder floats up under the buoyancy of the water, the clutch device is separated, and the power of the motor is only t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com