Steel pipe pile

A technology of steel pipe piles and steel plates, which is applied in the field of friction piles, can solve the problems of increased cost, low structural strength and reduced reliability of the connection between the eversion flange and steel pipe piles, and achieve the effect of improving the bearing capacity of single piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

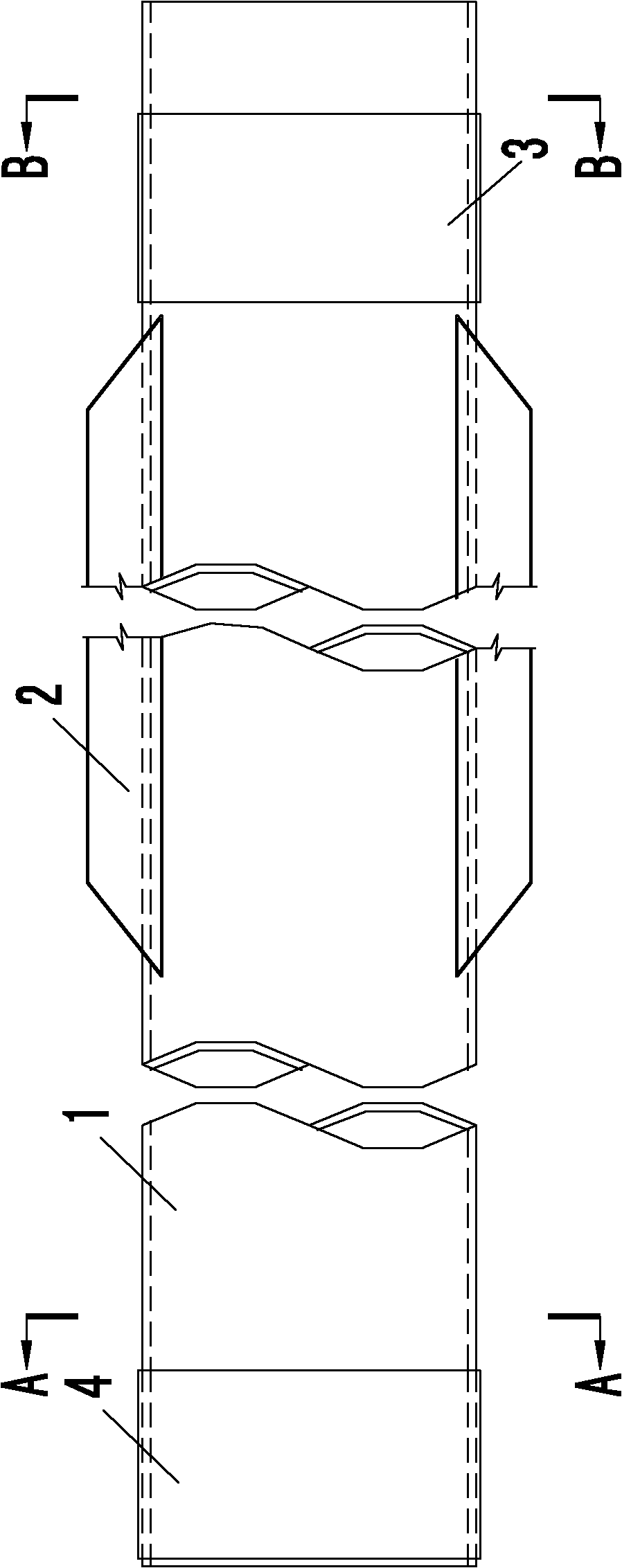

[0020] The selection of the bearing layer at the pile tip is an important control factor in pile foundation engineering. When there is a contradiction between the design of the bearing capacity of the single pile, the bearing layer at the pile tip and the pile sinking conditions, it is necessary to find a technical measure to solve the problem. Balance the contradictions among these three factors, and achieve the expected bearing capacity of single pile under the premise of satisfying the bearing layer at the pile end and pile sinking conditions.

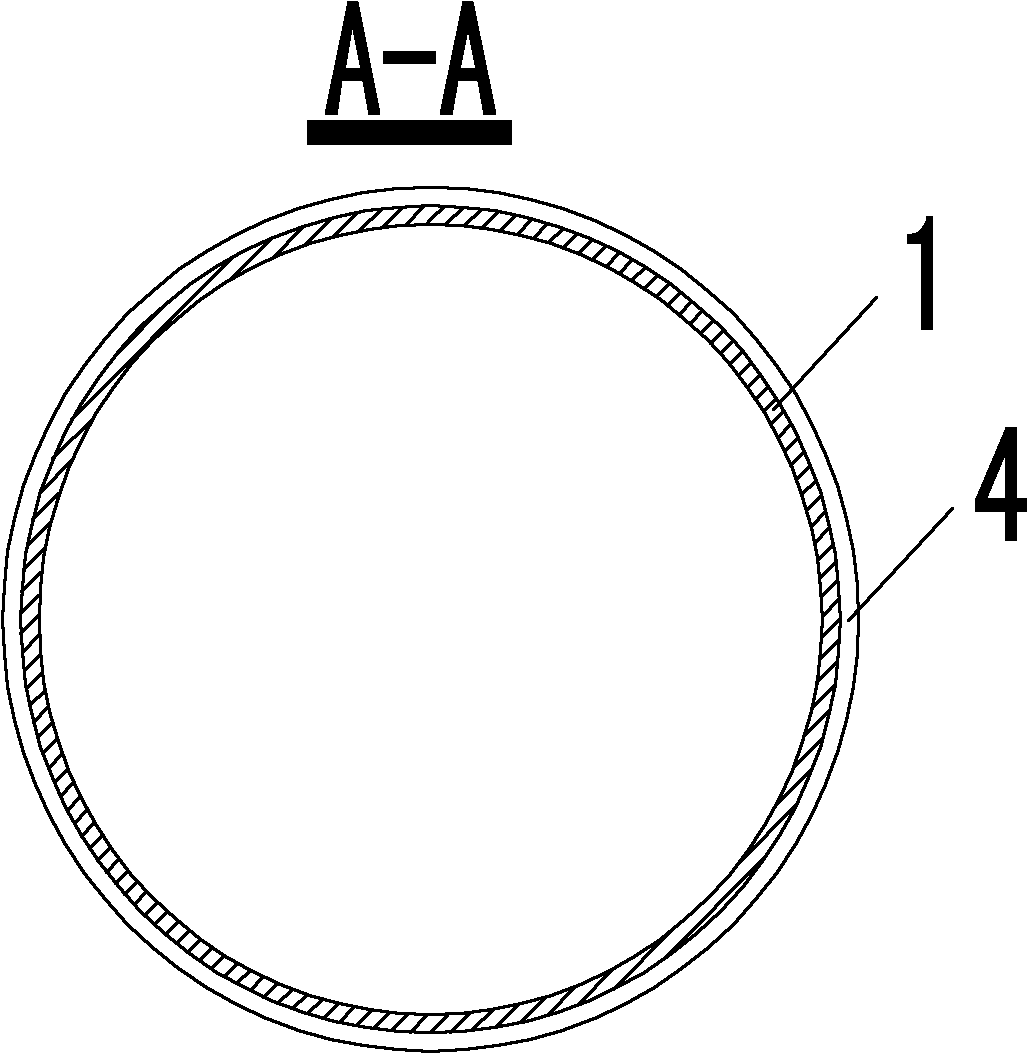

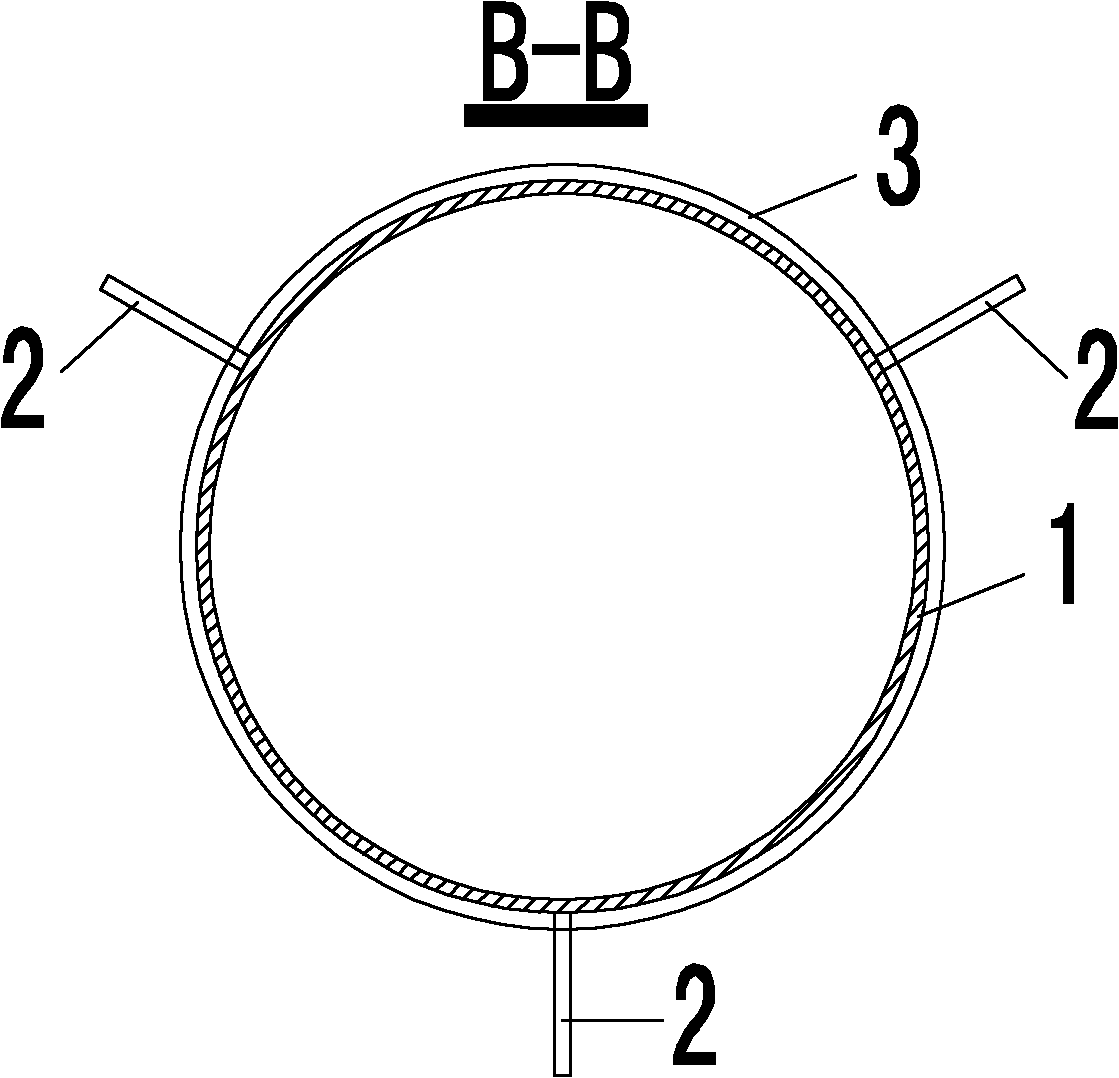

[0021] The single pile bearing capacity of the friction pile is mainly provided by the pile side friction resistance, which has two determining factors, one is the friction strength per unit area, and the other is the friction area. The frictional strength per unit area is determined by geological conditions and generally cannot be changed; while the pile side area can be improved by some measures. According to the material characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com