Gasholder load prediction equipment and method and gas scheduling system and method

A load forecasting and gas technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of unable to balance and schedule the gas system, and achieve the effect of improving the scheduling level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings.

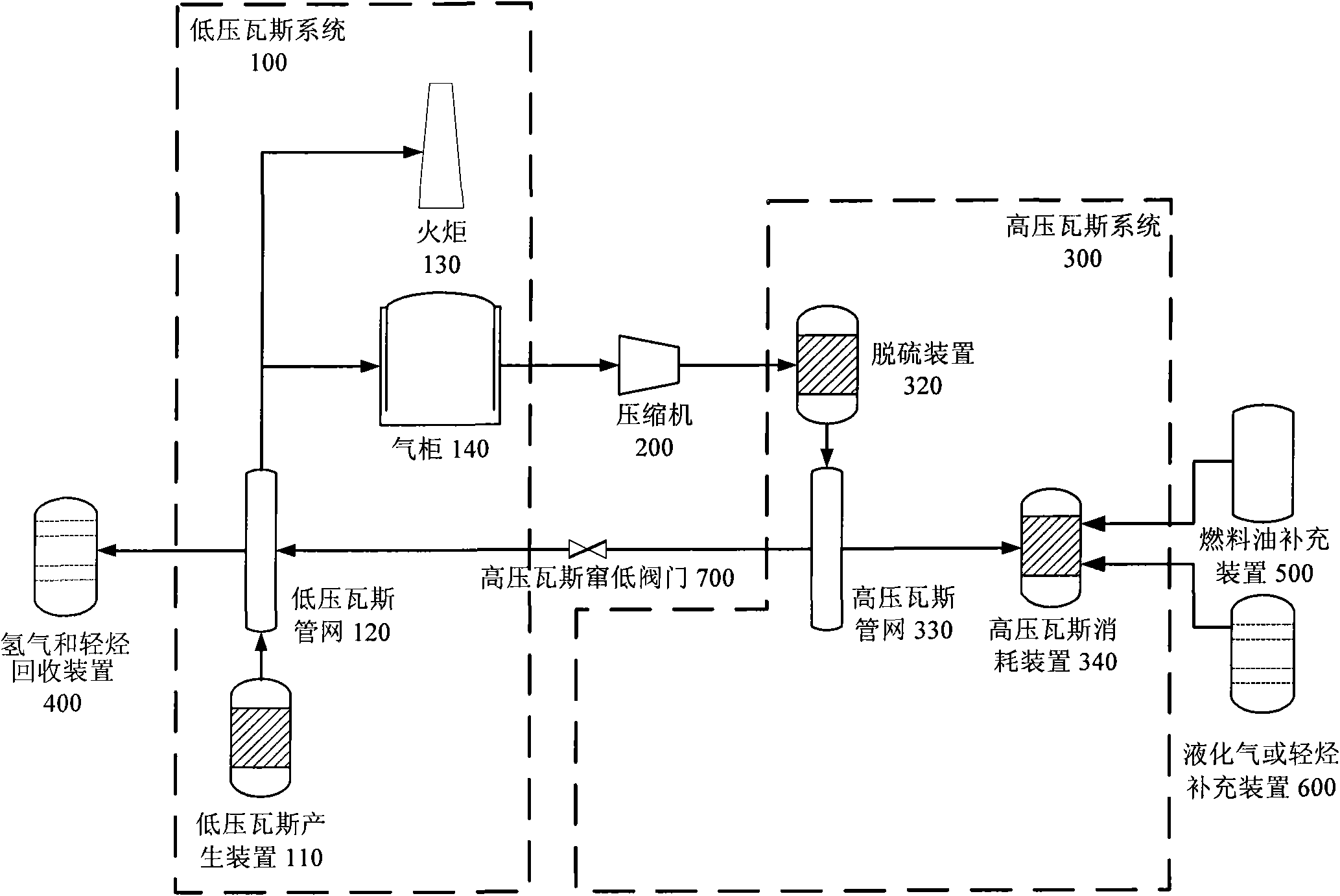

[0015] figure 1 The structure of the gas system is shown. Such as figure 1 As shown, the gas system includes a low-pressure gas system 100, a compressor 200, a high-pressure gas blow-down valve 700, and a high-pressure gas system 300. The low-pressure gas system 100 includes a low-pressure gas generator 110, a low-pressure gas pipeline network 120, a flare 130 and Cabinet 140, the low-pressure gas generating device 110, flare 130 and gas cabinet 140 are all connected to the low-pressure gas pipe network 120; the high-pressure gas system 300 includes a high-pressure gas pipe network 330 and a high-pressure gas consumption device 340, and the high-pressure gas consumption device 340 The high-pressure gas pipe network 330 is connected; the inlet end of the compressor 200 is connected with the gas cabinet 140, and the outlet end is connected with the high-pressure gas pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com