Product on-line detector

A technology for detectors and products, which is applied in the direction of optical testing for flaws/defects, etc., can solve problems such as prone to misjudgment, inconsistent testing standards, time-consuming and manpower consumption, and achieve the effect of saving manpower and testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

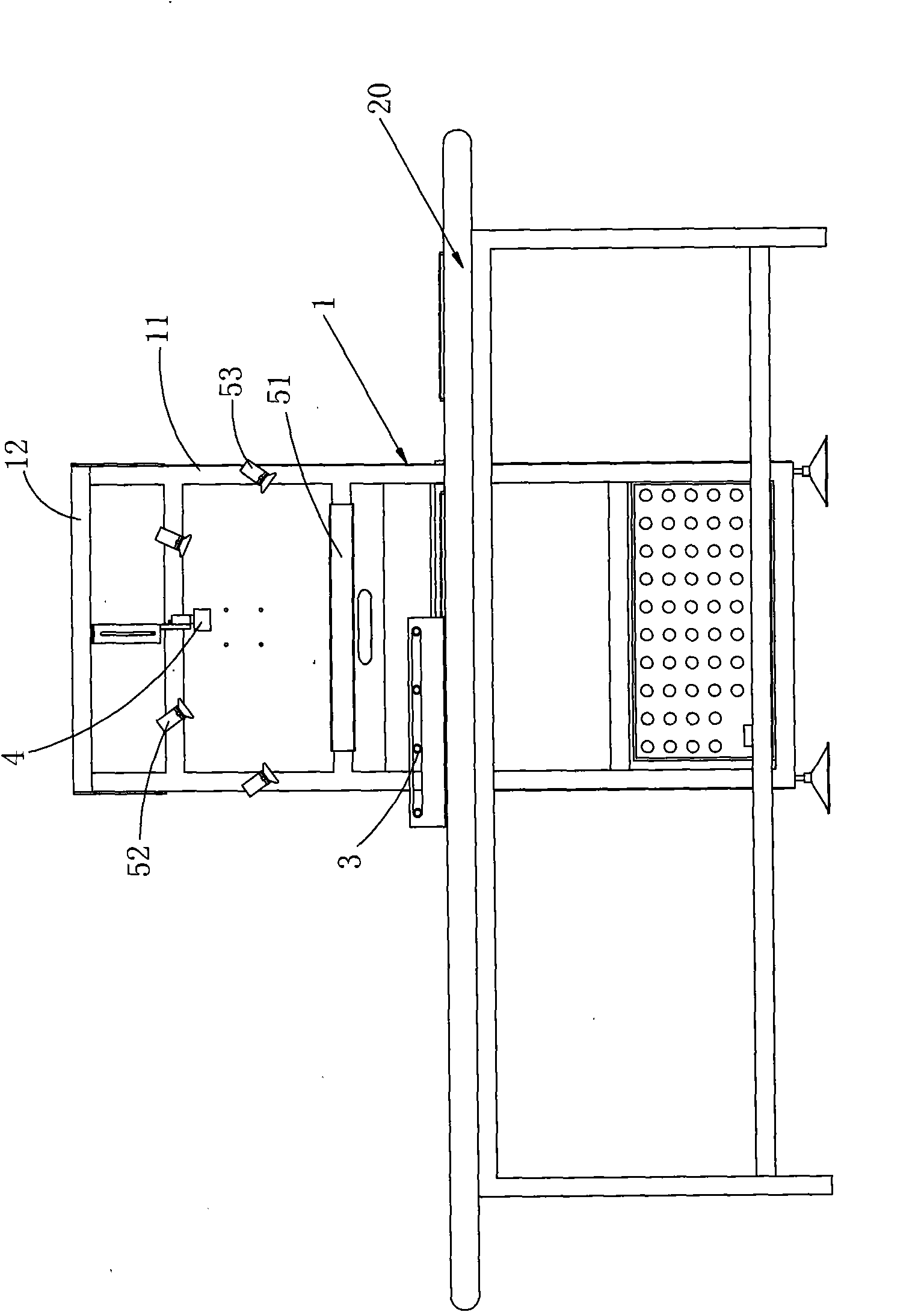

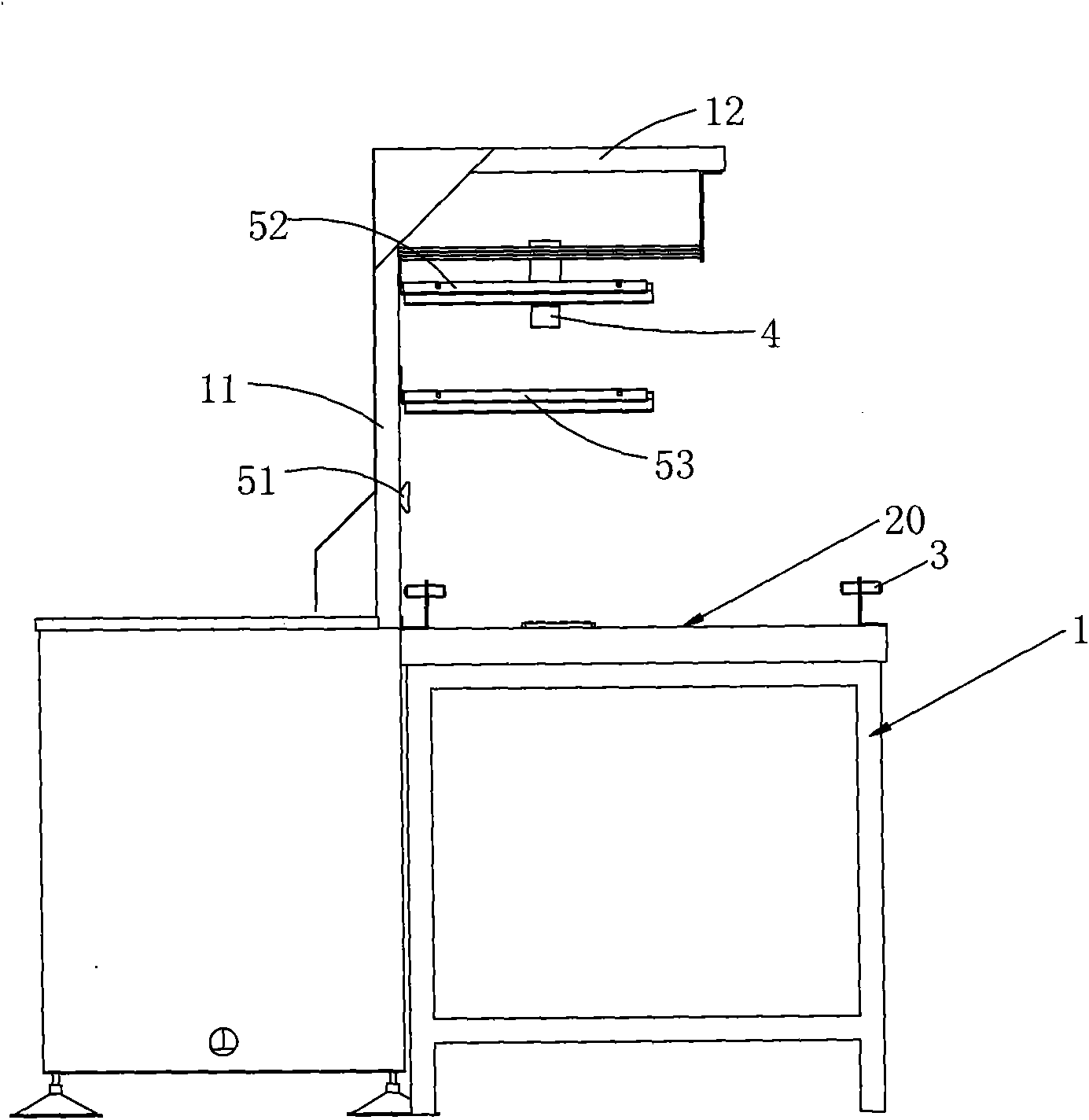

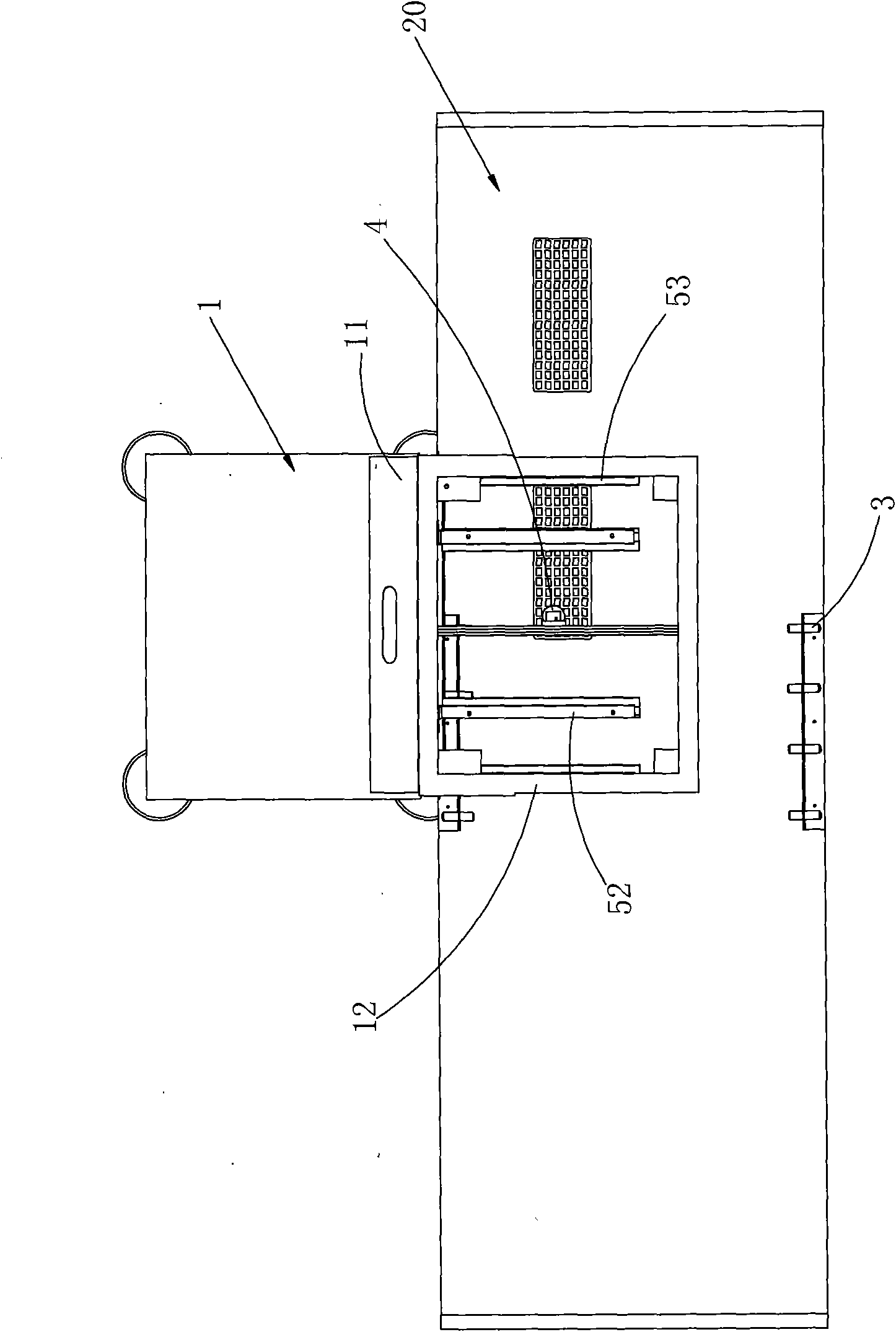

[0024] Embodiment: a kind of product online tester, this tester comprises:

[0025] Rack 1 is placed on one side of the production line 20: the side of the frame close to the production line 20 is provided with a mounting frame 11, and the top of the mounting frame 11 extends toward the production line to form a hanger 12 directly above the production line 20 ;

[0026] The camera 4 is fixedly positioned on the hanger 12: the camera port of the camera 4 faces the production line 20; the camera 4 is connected to the industrial computer through an image acquisition card, and is controlled by the industrial computer and transmits the captured image information to the industrial computer;

[0027] At least one lighting lamp is fixedly placed on the installation frame 11: the lighting light is irradiated on the production line area facing the camera port of the camera 4; the lighting lamp is connected to the COM port of the industrial computer through the optical coupling terminal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com