System for testing dynamic parameter of high-speed electromagnetic valve for knitting machine

A high-speed solenoid valve and dynamic parameter technology, applied in circuit breaker testing and other directions, can solve problems such as lack of detection, lagging detection methods, and inability to detect product dynamic response performance, and achieve the effect of convenient use and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

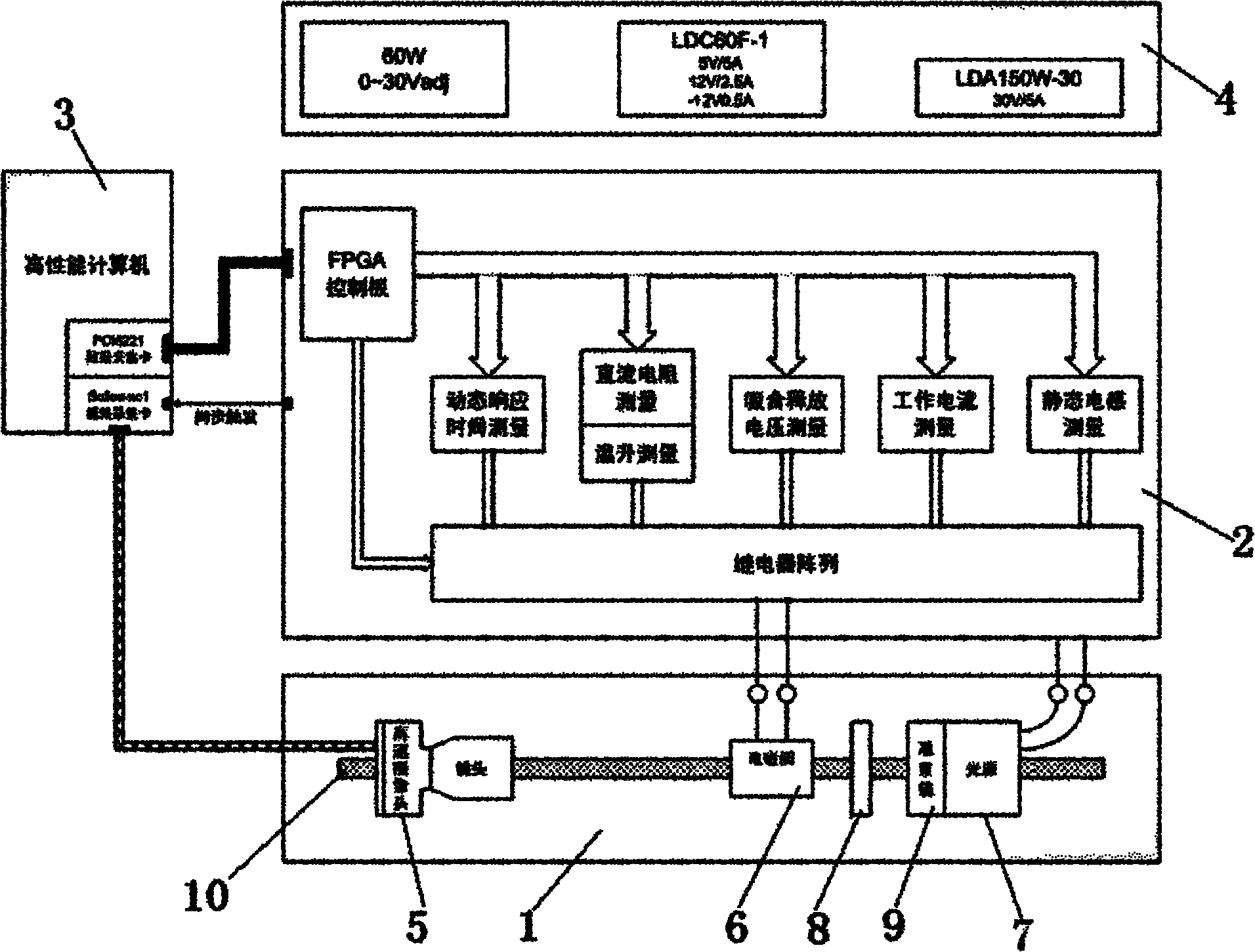

[0036] Such as figure 1 , 2 As shown, the test system of the present invention is composed of four parts: a test bench 1 , a measurement and control circuit board 2 , a host computer 3 and an external power supply module 4 .

[0037] The main body of the test bench 1 is an optical bench, which is equipped with a movable clamping mechanism for fixing the high-speed line array camera 5, the electromagnetic valve to be tested 6, the light source 7 and other related equipment. The high-speed line array camera 5 is coaxial with the spool of the solenoid valve 6 to be tested and the light source 7, and the camera 5 captures the action images of the spool of the solenoid valve 6 to be tested for analysis by the host computer. The test bench 1 provides measurement terminals for connecting the solenoid valve 6 to be tested and the measurement and control circuit board 2 .

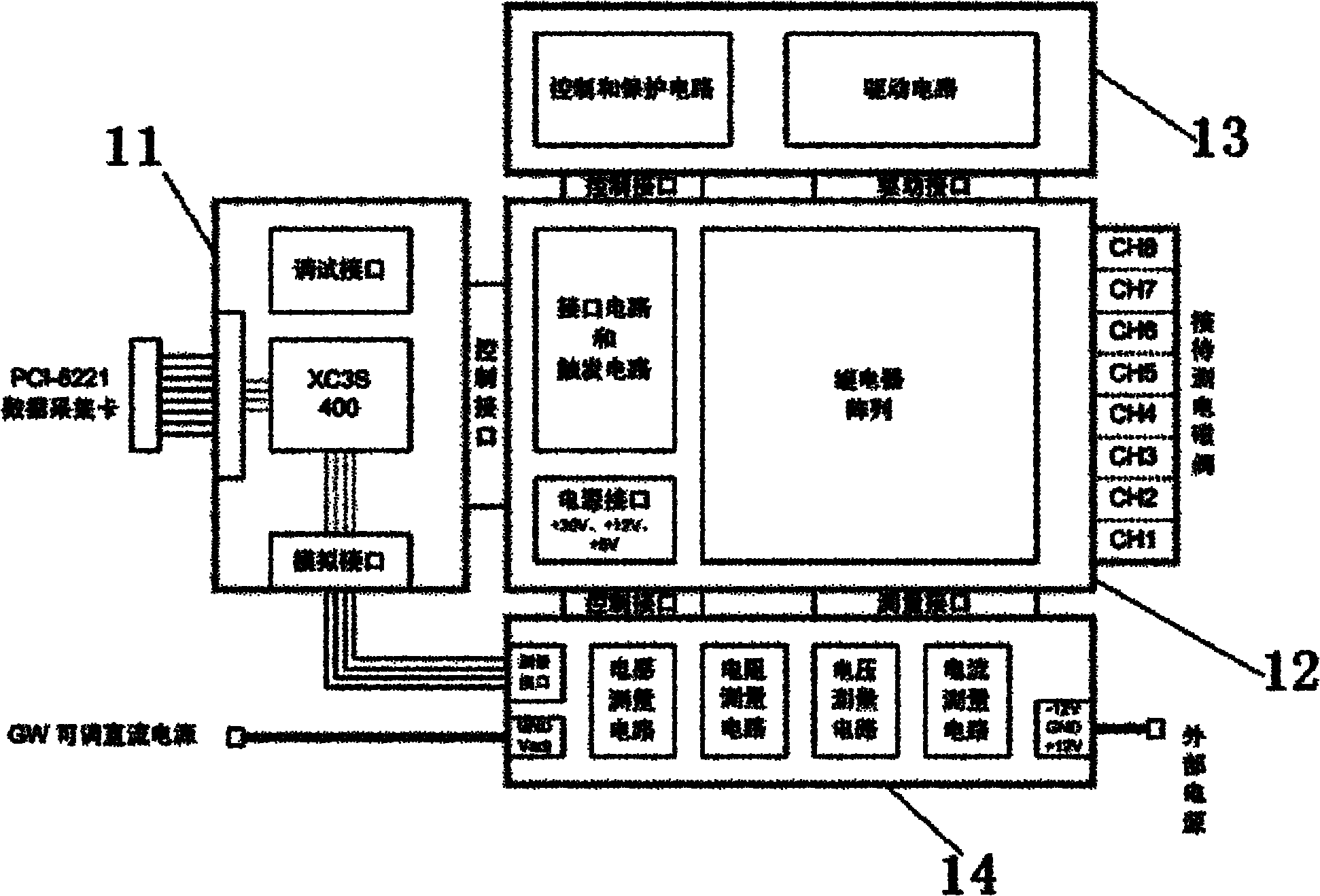

[0038] The measurement and control circuit board 2 takes FPGA as the control core, and includes the interface c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com