Optical unit and backlight unit using the same

A technology of optical unit and backlight unit, which is applied in the direction of optical components, optics, nonlinear optics, etc., and can solve the problems of general products without structure and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0118] Hereinafter, although this invention is demonstrated in full detail based on an Example, this invention is not limitedly interpreted based on description of this Example.

[0119]

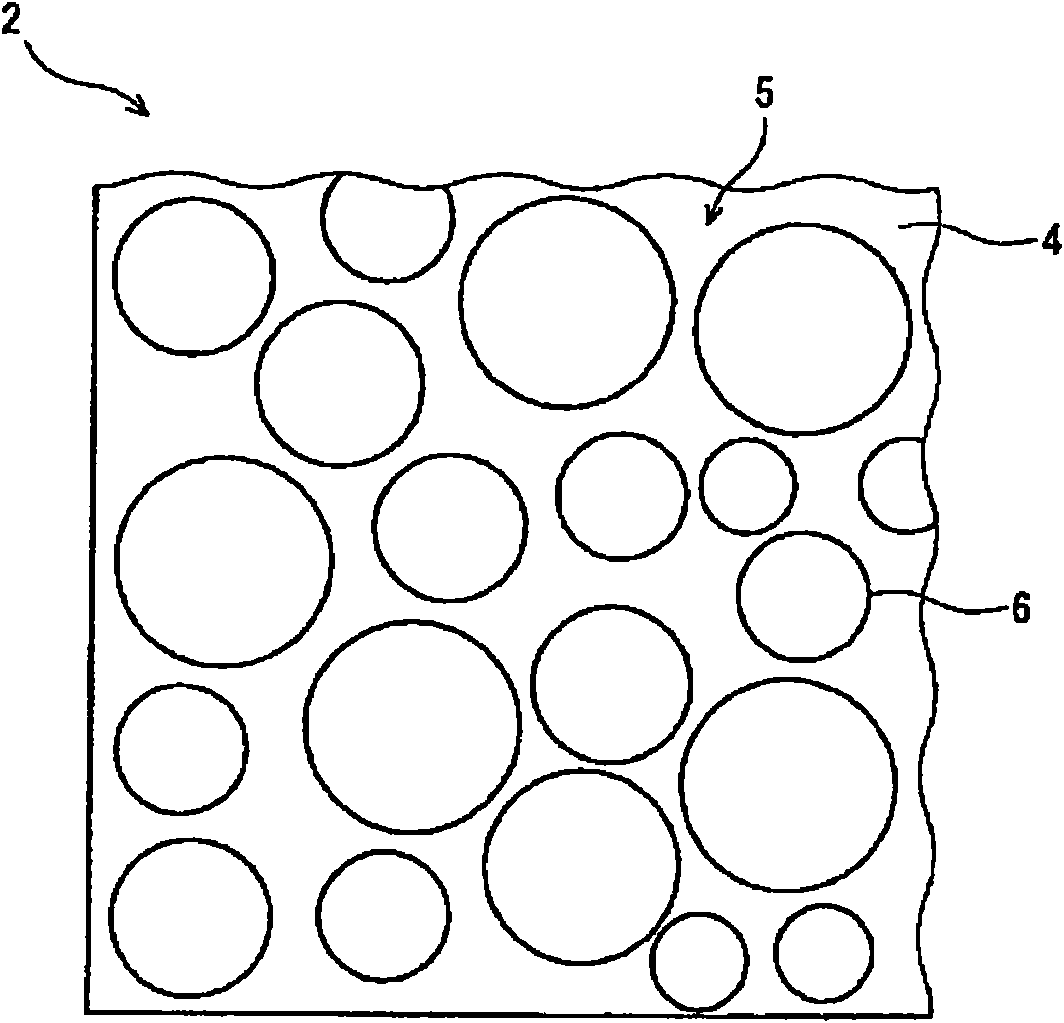

[0120] A microlens sheet is formed by laminating molten polycarbonate resin on a reverse-shaped sheet mold having a microlens array, and peeling off the sheet mold. The formed microlens sheet had an average thickness of 100 μm, an average microlens diameter of 60 μm, and a microlens diameter variation coefficient of 50%.

[0121]

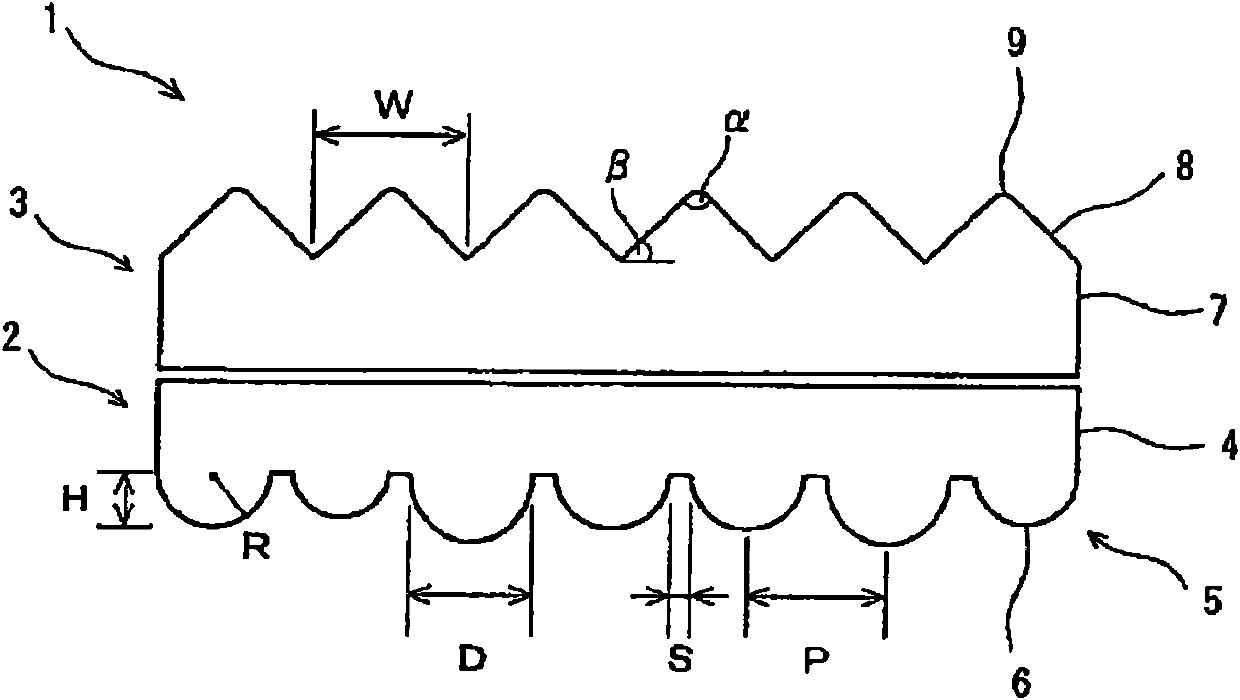

[0122] A prism sheet is formed by laminating molten polycarbonate resin on a sheet mold having a reverse shape of the prism sheet and peeling off the sheet mold. The formed prism sheet was formed with an average thickness of 100 μm and a width of the bottom surface of the rib prism portion of 100 μm.

[0123] [Example]

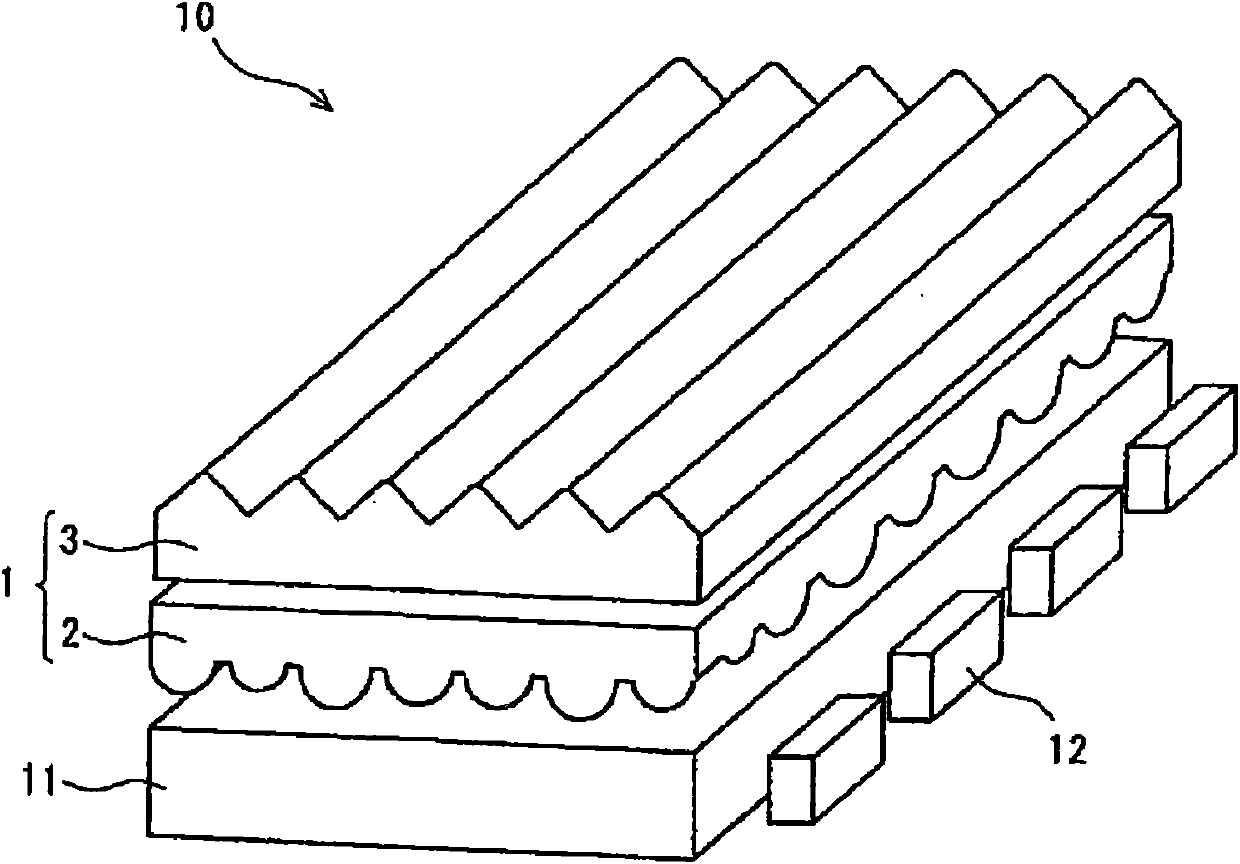

[0124] Light emitting diodes were arranged as light sources on the side end surfaces of the light guide plate with a thickness of 3 mm. On...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com